No programming method for machining of numerically controlled gear hobbing machine

A programming method and hobbing machine technology, applied in the direction of program control, computer control, general control system, etc., can solve the problems of long production cycle, high professional technical requirements, high professional requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0127] The present invention will be further described below in combination with specific embodiments.

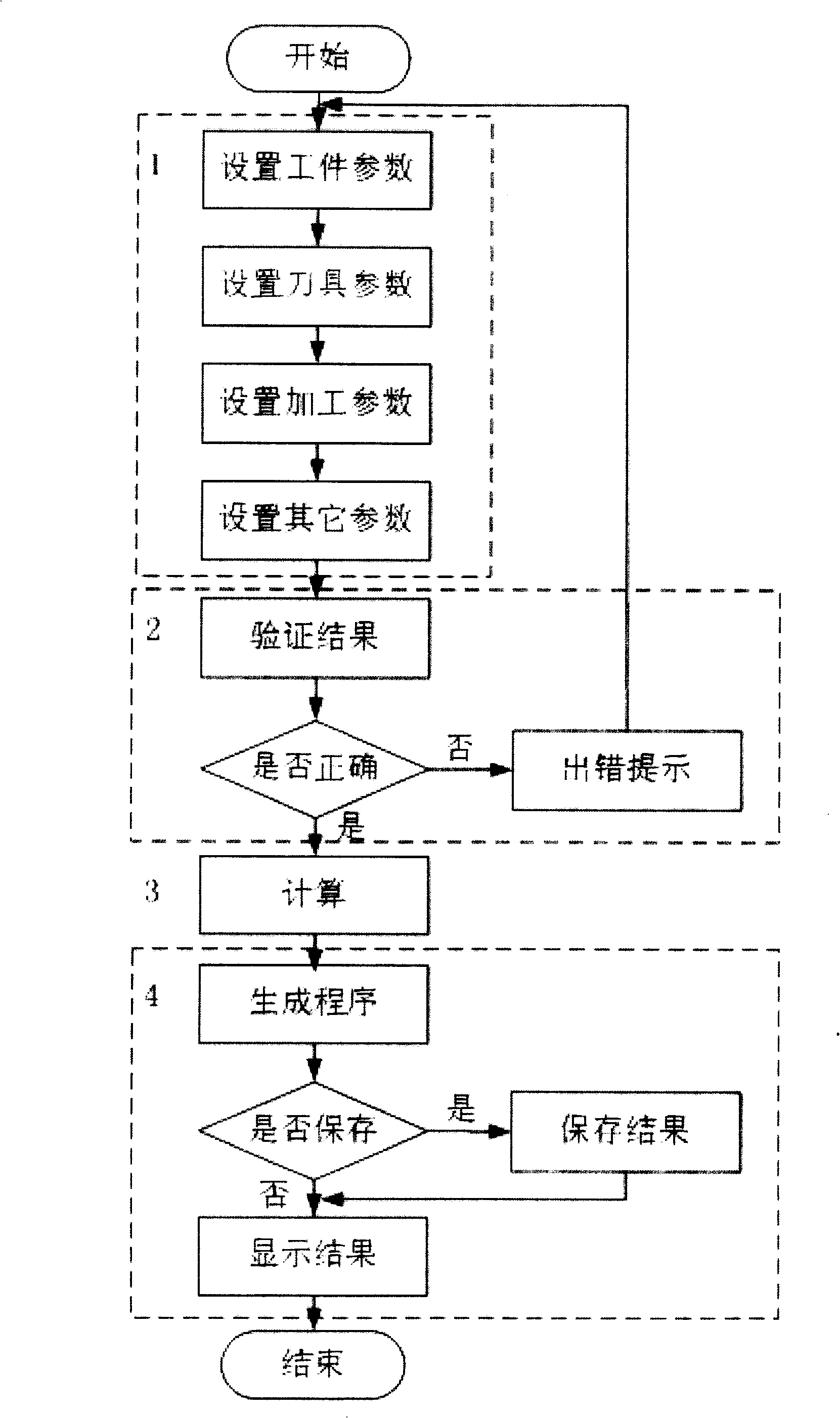

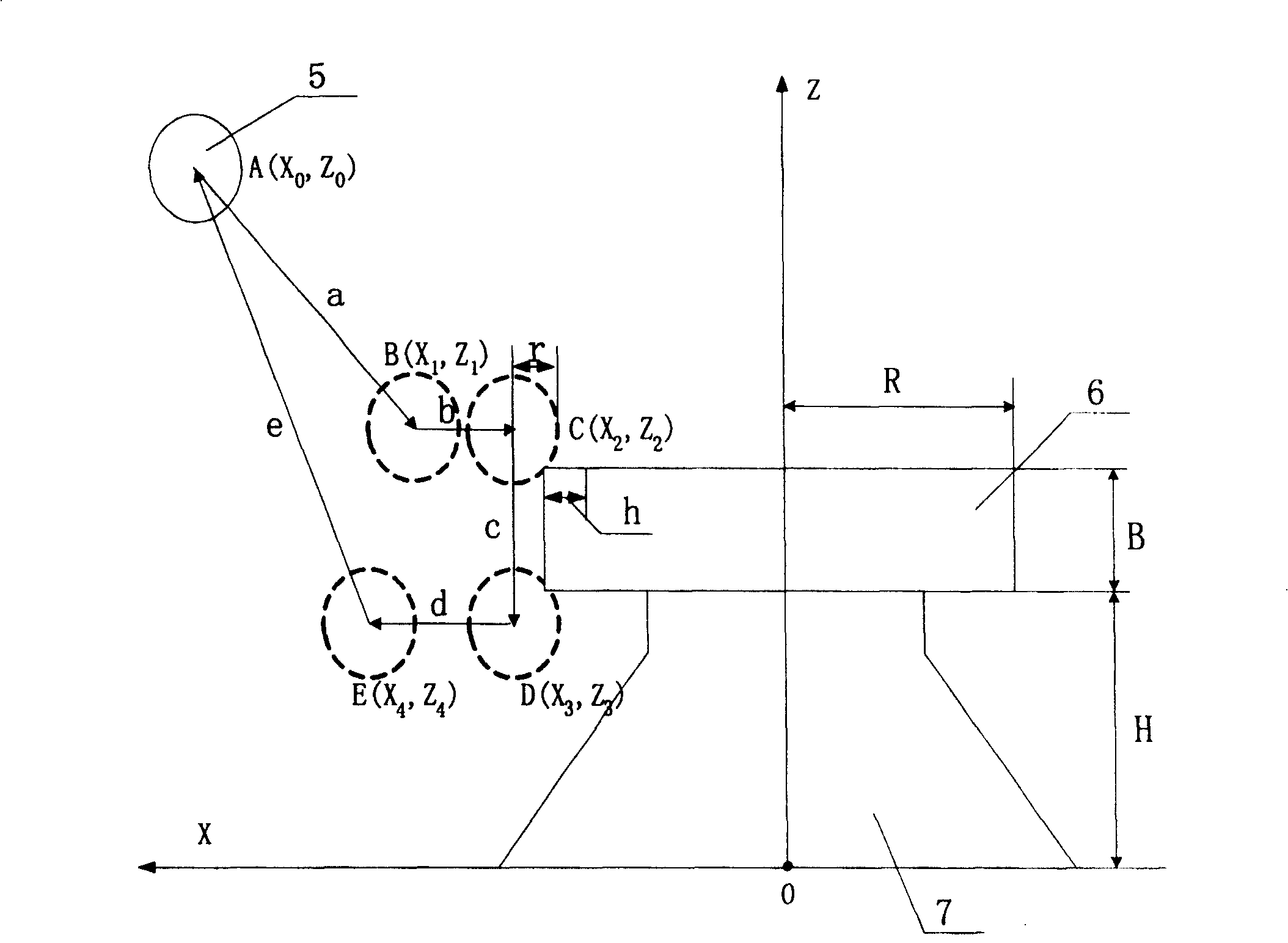

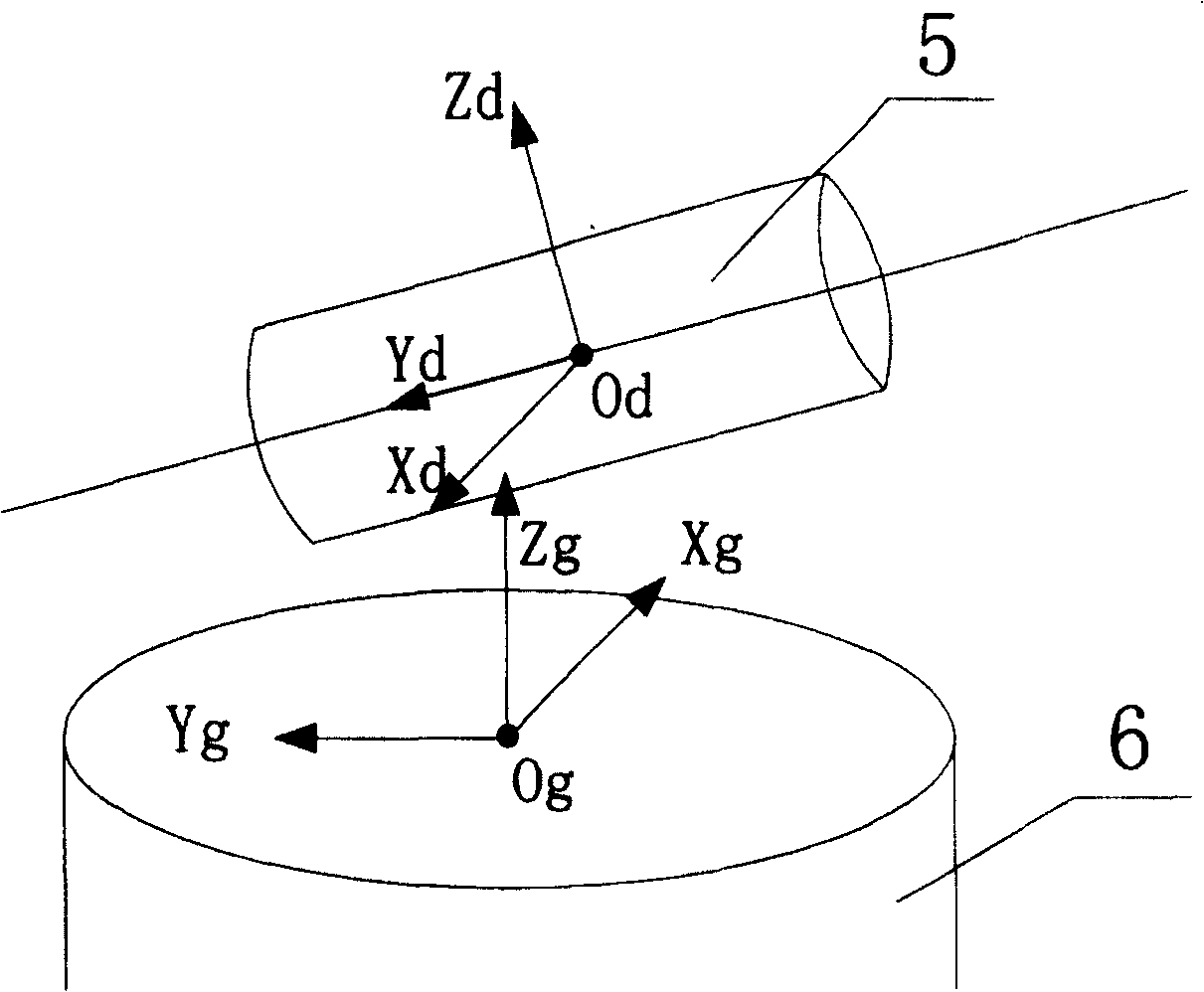

[0128] like Figure 1-Figure 7 As shown, the present embodiment utilizes the keyboard and numerical control system carried by Siemens (SINUMERIK 840D) numerical control system, and develops and embeds the program of the present invention into the SINUMERIK 840D numerical control software in combination with the Siemens HMI-OEM development platform, and automatically generates the gear processing NC through the control of the program of the present invention. code. A zero-programming method for CNC gear hobbing machine processing single-joint cylindrical spur gear / up milling processing / one-time feed method, the method steps are as follows:

[0129] (1) Setting parameters

[0130] In the parameter setting module, use the keyboard that comes with the CNC system to set the following parameters of the single spur gear:

[0131] ①Set workpiece parameters

[0132] The setting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com