Equipment management network monitoring system

A technology for network monitoring and equipment management, applied in general control systems, control/regulation systems, computer control, etc., can solve problems such as factory economic losses, difficulty in ensuring accuracy, and rough data, and improve the level of informatization and production. process, the effect of optimizing the manufacturing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

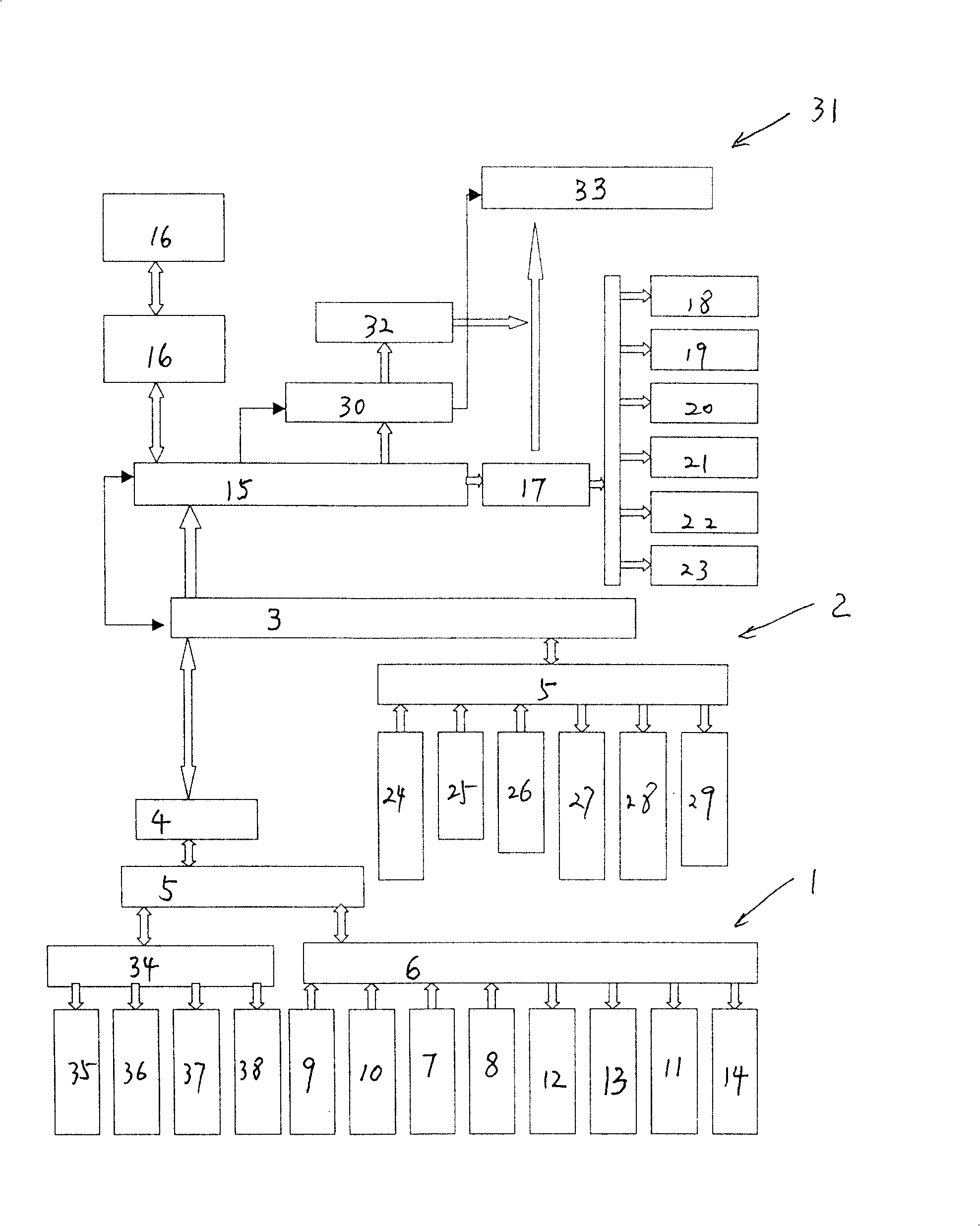

[0015] The standard configuration of the present invention takes 15 devices as a group, 16 constitutes 1 system unit, and a system unit can monitor up to 240 devices; multiple systems can share a database to monitor thousands or even tens of thousands of devices, the specific quantity It depends on the performance of the enterprise computer network and the capacity of the data server.

[0016] The present invention is mainly composed of a field device bus network system 1 and a computer device monitoring system 2. The field device bus network system 1 uses a high-performance programmable logic controller PLC or an industrial computer 3 to cooperate with an intelligent remote module, and connects remotely through an industrial bus 4. The I / O module 5 samples data and connects with the terminal adapter 6 on the device side to realize the detection and display of the device status.

[0017] The terminal adapter in the field device bus network system mainly inputs the start signal 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com