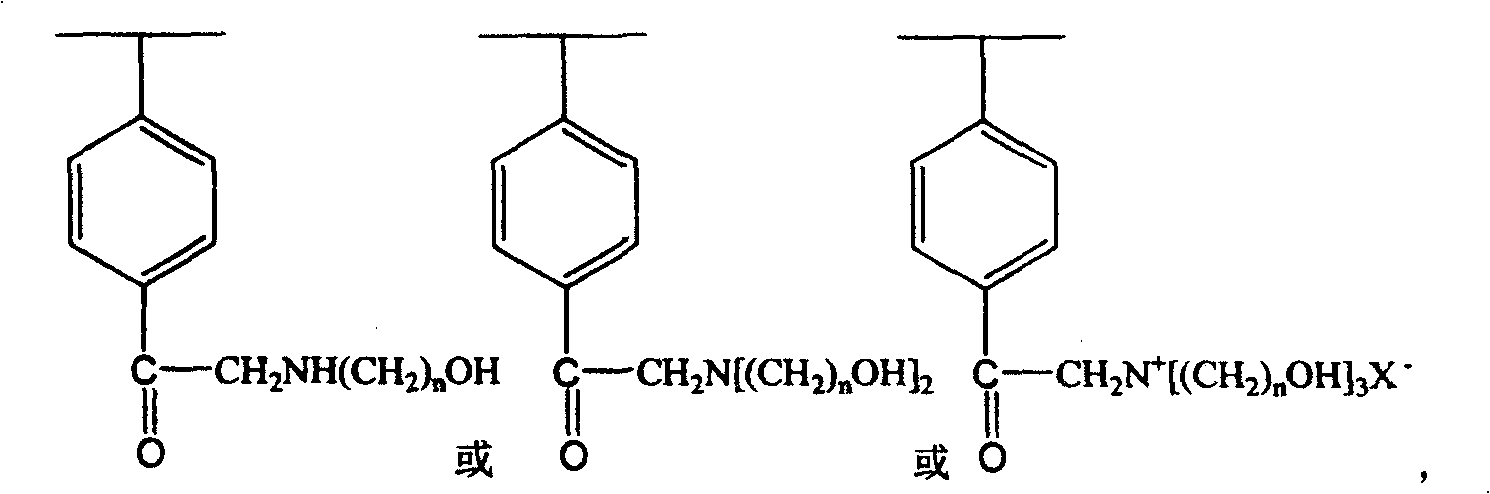

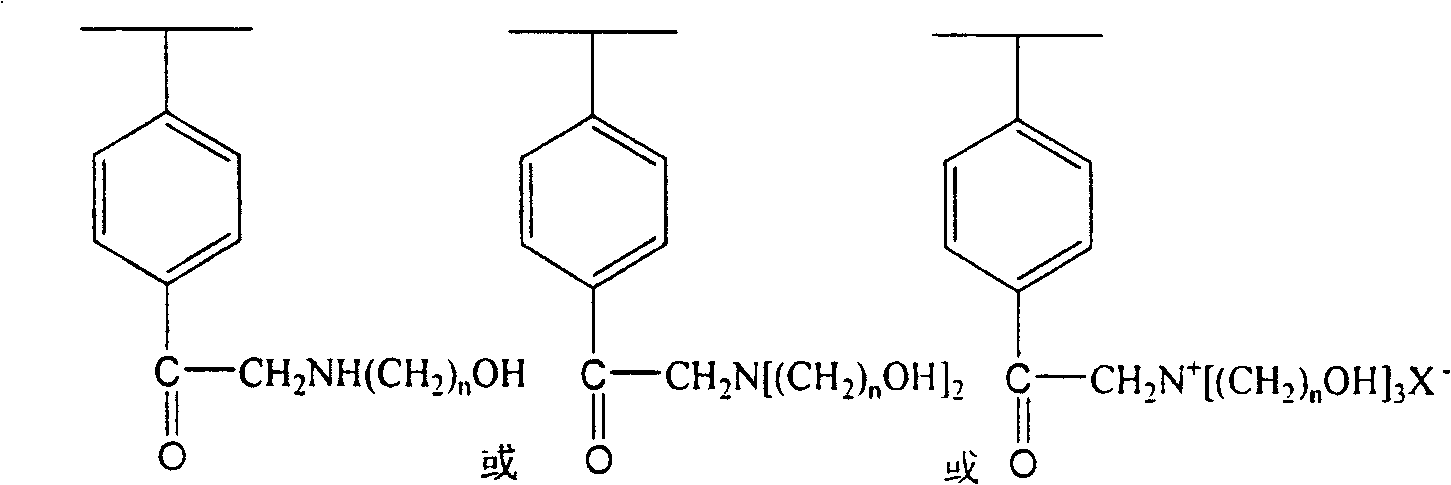

A hydroxylamine type chelating absorption resin and method for preparing the same

A chelation adsorption, polystyrene hydroxylamine-type technology, applied in the field of functional polymers, can solve problems such as the complex structure of chloromethylated resins, and achieve the effects of easy loading, high conversion rate, and definite adsorption resin structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Take 1g of PS-Ace-Cl resin (crosslinking degree: 7% (v / v) DVB; particle size 200μm) in a round bottom beaker, add 4ml of dioxane, swell for 12h, add 1ml of diethanolamine, stir to disperse Evenly, react at 110°C for 13h under normal pressure. That is, a hydroxylamine-type resin with a supported amount of 0.97meq / g was obtained.

Embodiment 2

[0019] Take 1g of PS-Ace-Cl resin (crosslinking degree: 1% (v / v) DVB; particle size 200μm) in a round bottom beaker, add 4ml of tetrahydrofuran, swell for 15h, add 2ml of dibutanolamine, stir to make it evenly dispersed , Reacted at 40°C for 6h under normal pressure. That is, a hydroxylamine-type resin with a supported amount of 1.15 meq / g was obtained.

Embodiment 3

[0021] Take 1g of PS-Ace-Br resin (crosslinking degree: 1% (v / v) DVB; particle size 200μm) in a round bottom beaker, add 4ml of tetrahydrofuran, swell for 12h, add 1ml of diethanolamine, stir to make it evenly dispersed, React at 110°C for 18h under normal pressure. That is, a hydroxylamine-type resin with a supported amount of 3.19 meq / g was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com