Aluminium alloy solutionizing, aging gas-heating processing furnace

A technology of gas heating and aluminum alloy, which is applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of not being able to adapt to mass production, the production cycle cannot be synchronized, and the thermal efficiency is not high, and achieve compact structure, high production efficiency, and excellent performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

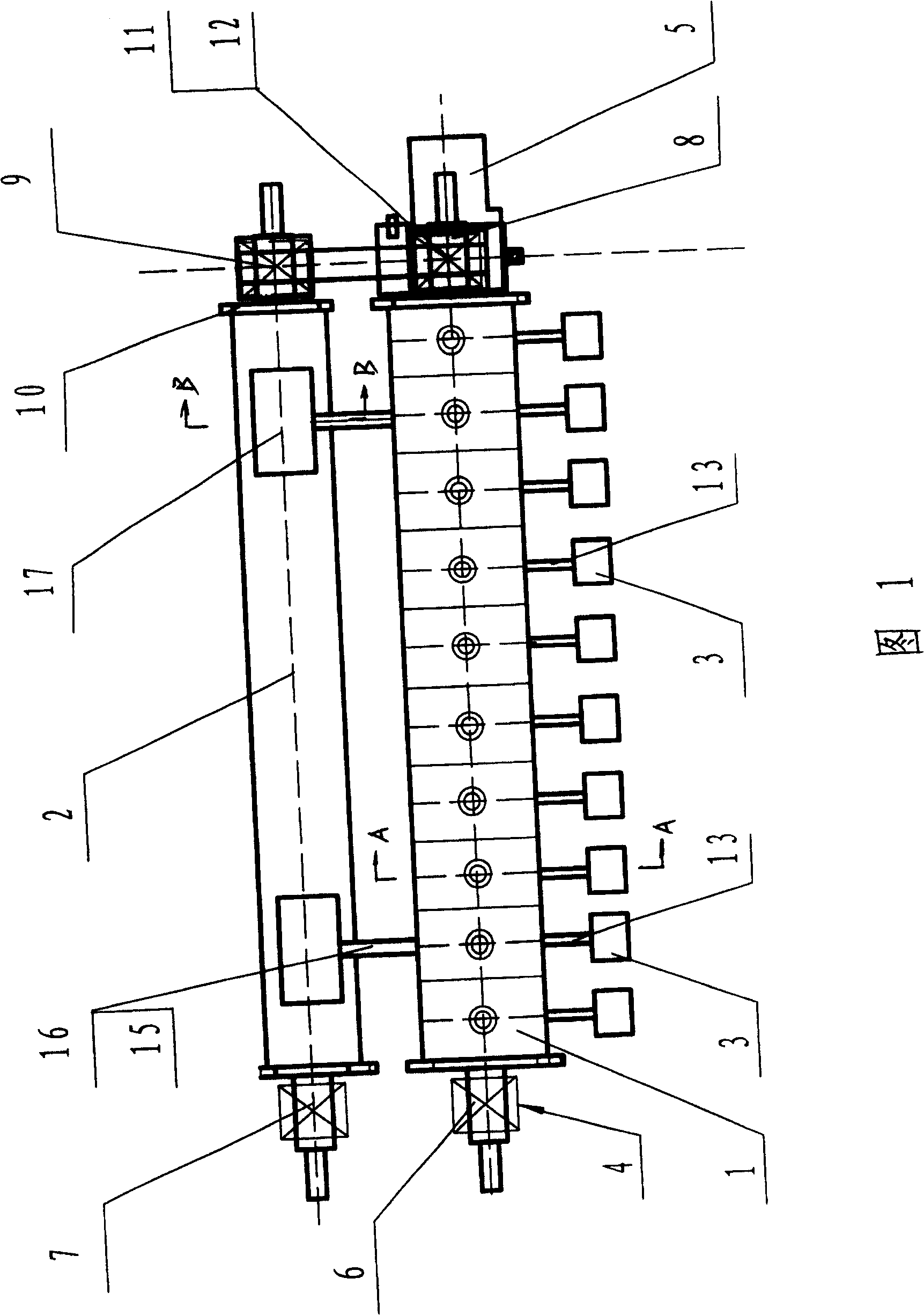

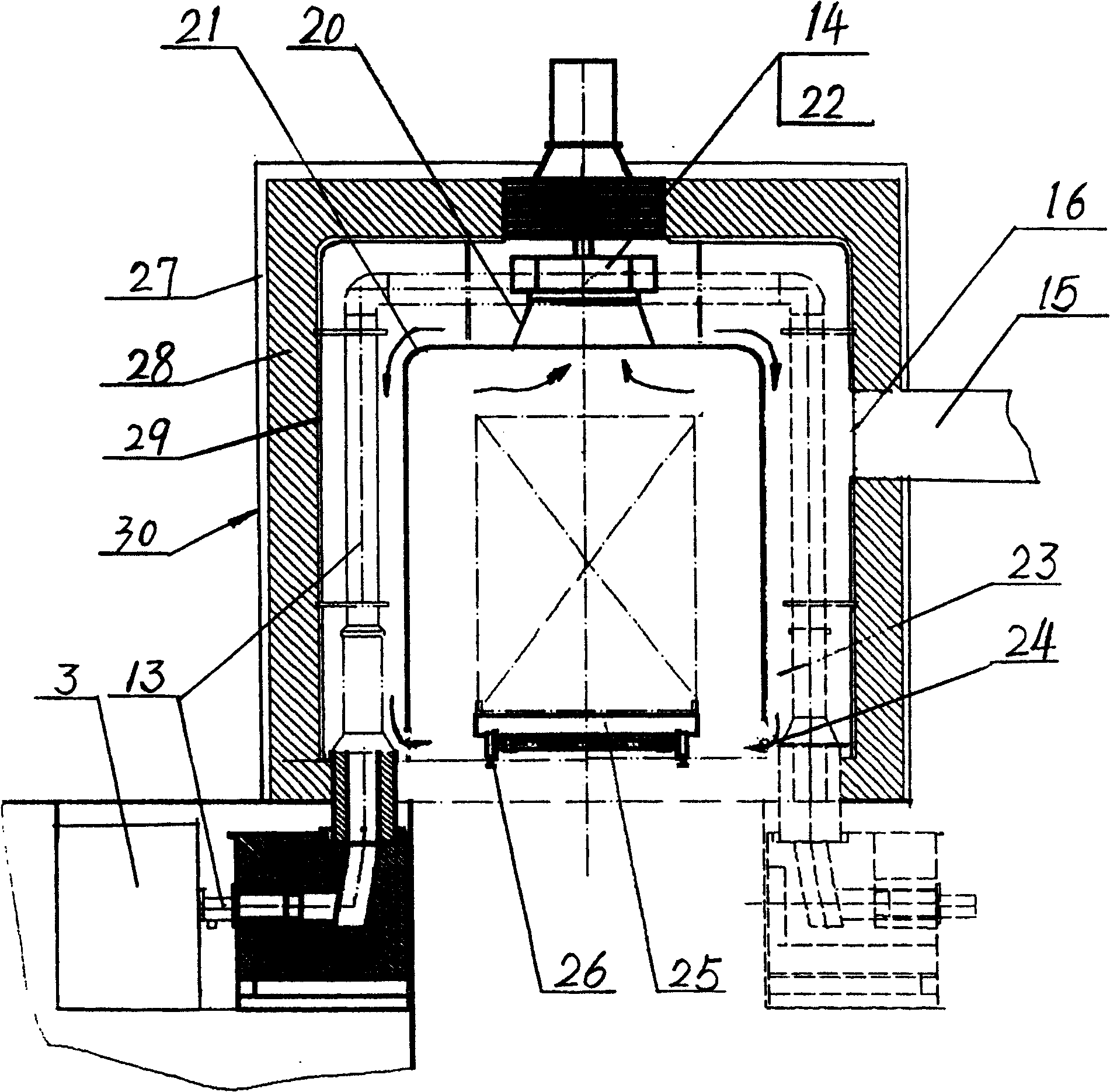

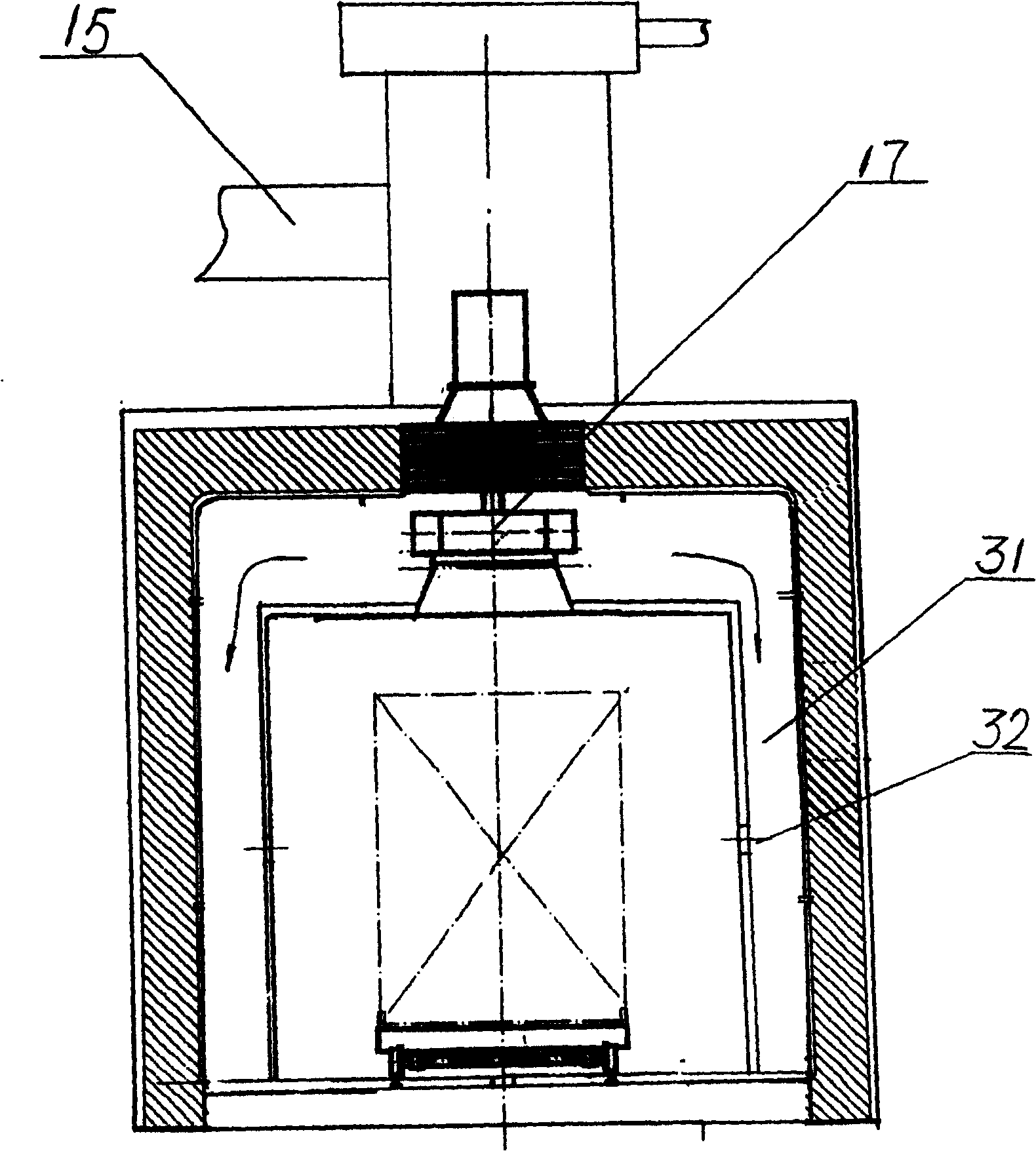

[0015] As shown in Figures 1 and 2, 1-solid solution furnace, 2-aging furnace, 3-combustion device, 4-hydraulic system, 5-quenching tank, 6-solid solution furnace pushing cylinder, 7-aging furnace discharging cylinder, 8-solid solution furnace discharge cylinder, 9-aging furnace push cylinder, 10-furnace door cylinder, 11-hydraulic hoist, 12-mobile flat car, 13-hot air pipe, 14-hot air mixed flow chamber, 15- Outer exhaust hot air pipe, 16-smoke exhaust port, 17-hot air generating room.

[0016] The heat treatment device of the present invention includes a furnace body part composed of a solid solution furnace 1 and an aging furnace 2, a combustion device 3 for providing high-temperature hot gas, and a hydraulic system 4 for causing displacement (forward, downward, upward, etc.) of the workpiece, using In the quenching tank 5 of the quenching process, the hydraulic system 4 mainly includes the solid solution furnace pushing cylinder 6, the aging furnace discharging cylinder 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com