Nickel aluminium alloy and preparation method thereof

A nickel-aluminum alloy and production method technology, applied in the field of alloys, can solve problems such as health injuries and pollution of on-site workers, and achieve the effects of good anti-corrosion performance, wide application range, and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

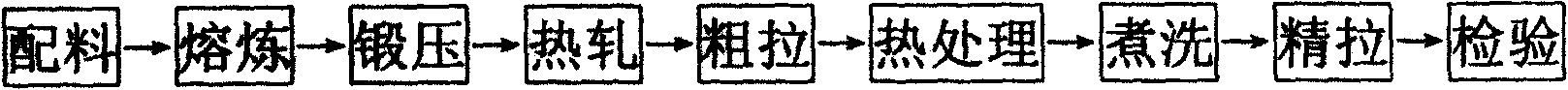

[0032] Embodiment of the present invention production process step process:

[0033] (1) Ingredients

[0034] Raw material composition weight ratio: 95% of nickel, 4.55% of aluminum, 0.15% of manganese, 0.15% of titanium sponge, and 0.15% of rare earth are equipped with raw materials;

[0035] The invention changes the relatively simple formula of the existing nickel-aluminum alloy wire, and adds trace elements, especially rare earth elements, into the formula, which plays a very important role in improving the performance of the product. At the same time, in the above-mentioned ingredients, the ratio of various ingredients is also very important. Adding aluminum and titanium elements to the nickel-based alloy can improve the bonding strength between the coating and the substrate. Aluminum element has a strong self-passivation effect, so it can improve the surface quality and corrosion resistance of the coating. Titanium has the characteristics of high strength, good corros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com