Hydrogenation cracking method of high-output diesel oil from high-nitrogen content heavy raw material

A technology of hydrocracking and high nitrogen content, applied in the field of hydrocarbon oil cracking, can solve the problems of increasing the load of the hydrotreating reactor, and achieve the effects of improving the efficiency of hydrodenitrogenation, increasing the yield, and avoiding the cracking reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

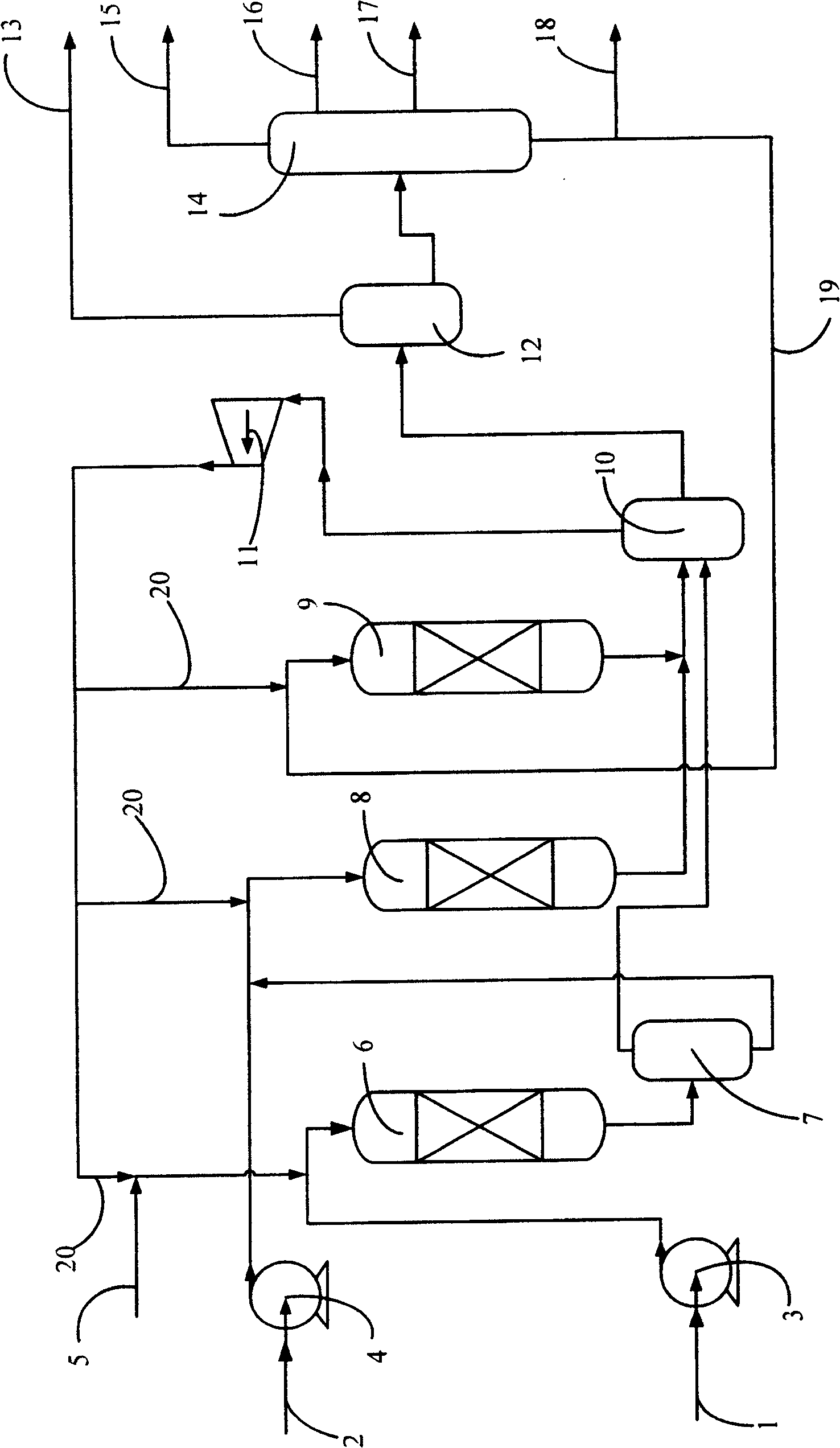

[0031] The feed oil A used in the embodiment is a heavy feed with high nitrogen content, and the feed oil B is a heavy feed with low nitrogen content. The difference is that the nitrogen content of feedstock oil A is 3100 μg / g, and the nitrogen content of feedstock oil B is 810 μg / g.

[0032] The trade names of the hydrorefining catalyst and the hydrocracking catalyst used in the examples are RN-2 and RT-30, respectively, produced by Changling Catalyst Factory of Sinopec Catalyst Company.

[0033] The raw material oil A enters the first hydrofinishing reactor, and the reaction product enters the hot flash tank, and the liquid phase stream at the bottom of the hot flash tank and the raw material oil B are mixed with hydrogen and enter the second hydrofinishing reactor for hydrogenation For the refining reaction, the weight ratio of feed oil A to feed oil B is 1:1. After the effluent of the second hydrofinishing reactor is mixed with the effluent of the hydrocracking reactor, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com