Method for producing low freezing point diesel oil with excellent quality by coked gasoline and diesel oil

A gasoline and diesel oil, high-quality technology, applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems of low cetane number of diesel oil, small freezing point depression, etc., to achieve the reduction of freezing point and freezing point Large and good pour point depressing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

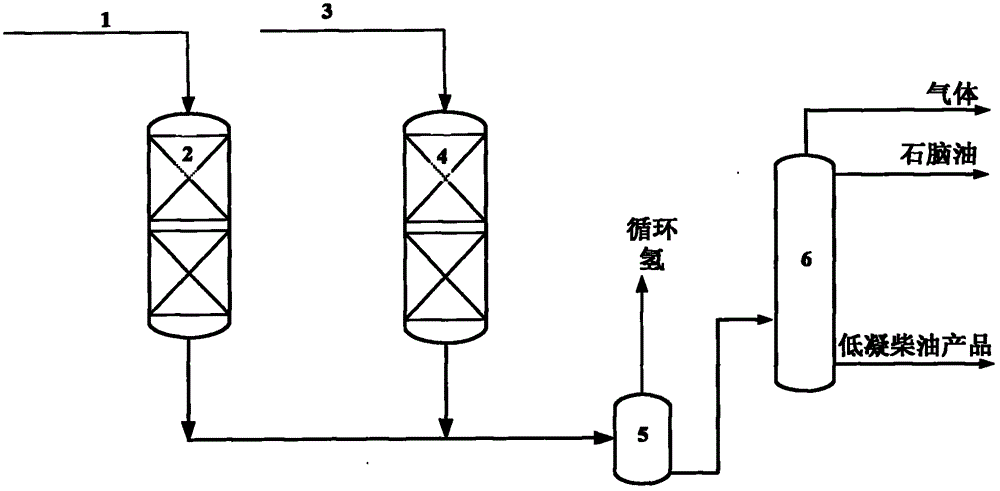

Method used

Image

Examples

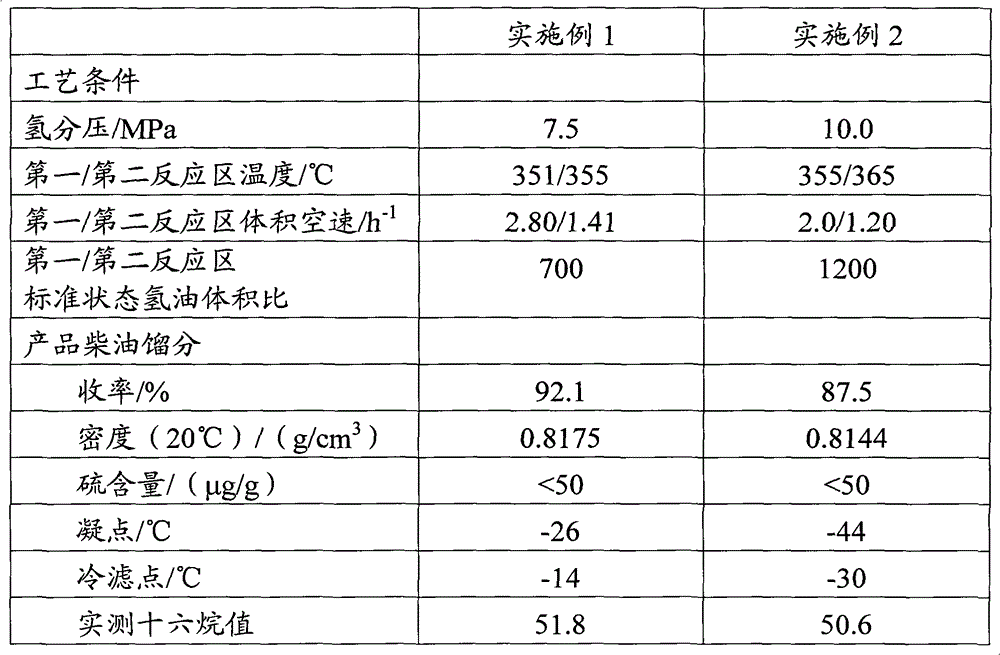

Embodiment 1

[0055] A coked gasoline A1 and a coked diesel A2 are used as raw materials. The first reaction zone is filled with hydrofinishing catalyst RS-1000; the second reaction zone is filled with hydrofinishing catalyst RS-1000, hydromodified decondensation catalyst D and hydrofinishing catalyst RS-1000 in sequence, and the catalyst in the second reaction zone The filling volume ratio is 60:40:5. In order to avoid coking, a small amount of protective agents RG-10A and RG-10B can be loaded on the upper part of the first and second reaction zones.

[0056] First, the raw material A1 is contacted with the RS-1000 catalyst in the first reaction zone to carry out hydrodesulfurization, hydrodenitrogenation, saturation reaction of olefins and aromatics. Raw material A2 first contacts with RS-1000 catalyst in the second reaction zone to carry out hydrodesulfurization, hydrodenitrogenation, hydrogenation and saturation reaction of olefins and aromatics; then it contacts with hydrogenation modif...

Embodiment 2

[0059] Using a kind of coked gasoline A1 and coked diesel oil A2 as raw materials, adopt the method of the present invention to depress the point, the first reaction zone is filled with hydrofinishing catalyst RS-1000; the second reaction zone is filled with hydrofinishing catalyst RS-1000, plus The filling volume ratio of the hydrogen-modified decondensation catalyst D and the hydrofinishing catalyst RS-1000 in the second reaction zone is 40:60:10. The properties of raw oil are listed in Table 1, and the reaction conditions and product properties are listed in Table 3.

[0060] It can be seen from the data in Table 3 that the freezing point of the diesel product was reduced to -44°C, the cold filter point was reduced to -30°C, the yield reached 87.5%, the cetane number increased to 50.6, and the sulfur content was greatly reduced.

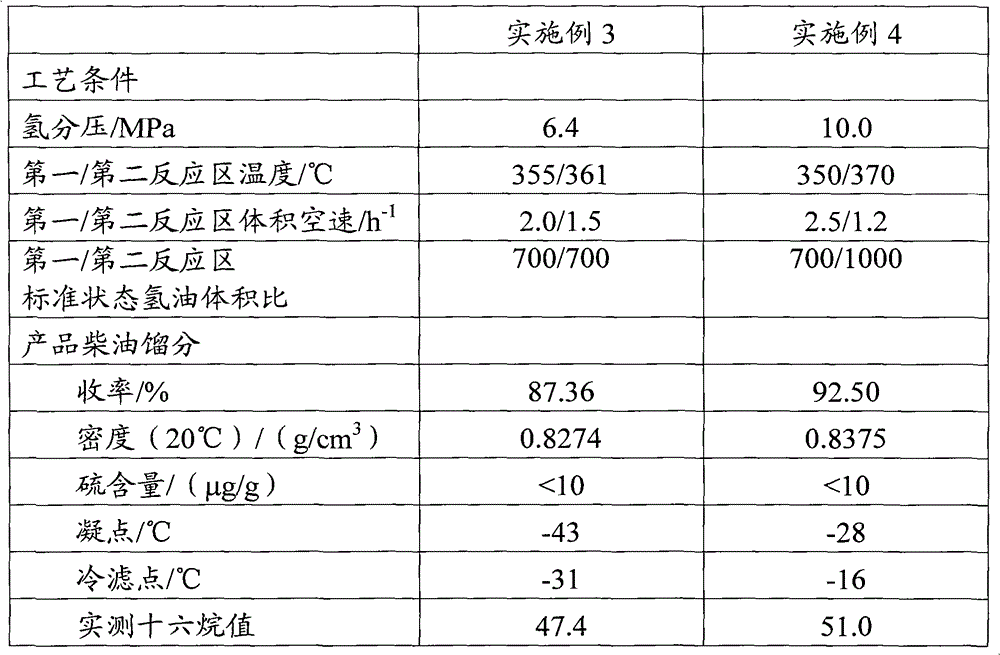

Embodiment 3

[0062] A kind of coked gasoline B1 and coked diesel oil B2 are used as raw materials, and the method of the present invention is used for depressing. The first reaction zone is filled with a hydrofinishing catalyst RS-1000; the second reaction zone is filled with a hydrofinishing catalyst RS-1000, plus The loading volume ratio of the hydrogen-modified decondensation catalyst D and the hydrofinishing catalyst RS-1000 in the second reaction zone is 50:50:30. The properties of raw oil are listed in Table 2, and the reaction conditions and product properties are listed in Table 4.

[0063] It can be seen from the data in Table 4 that the freezing point of the diesel product is reduced to -43°C, the cold filter point is reduced to -31°C, the yield reaches 87.36%, the cetane number increases to 47.4, and the sulfur content is greatly reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com