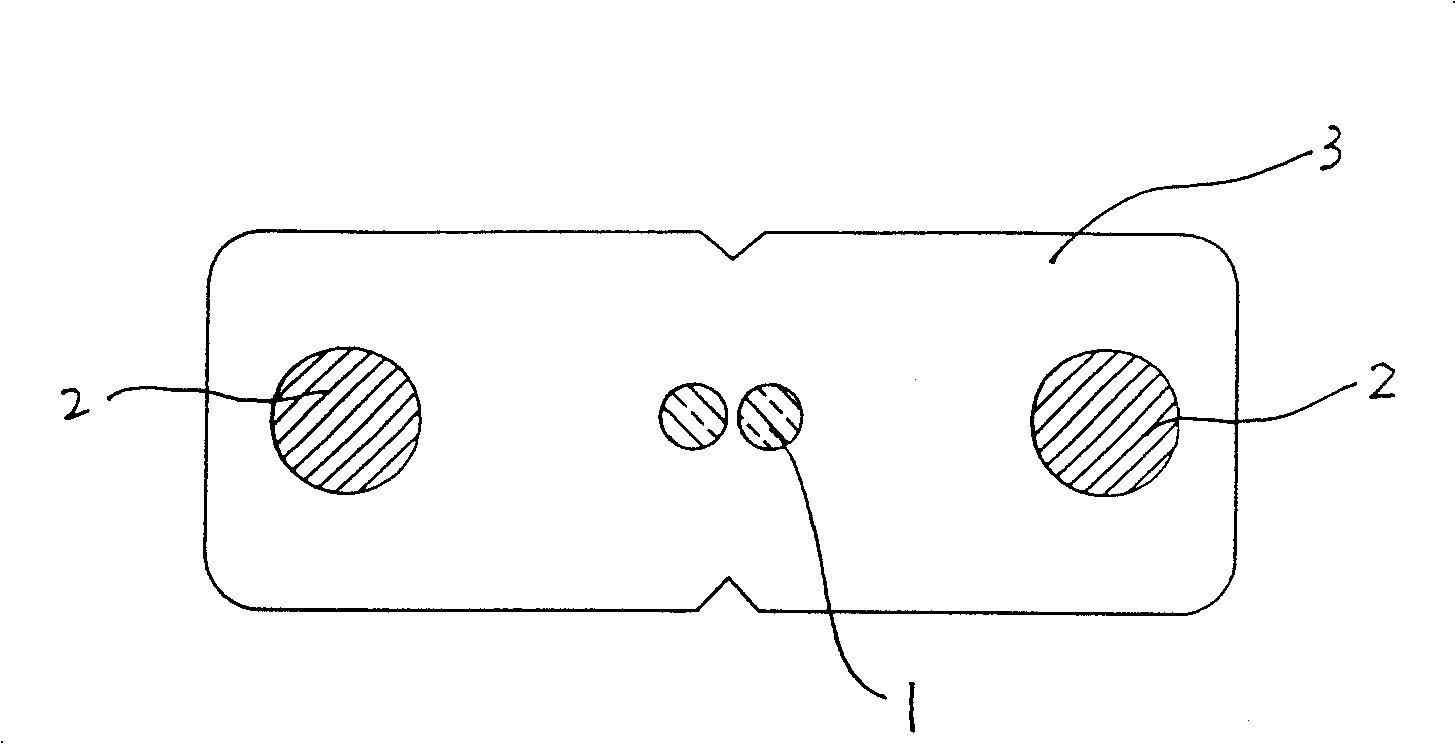

Aramid fiber reinforced plastic reinforcement, and its preparing process and use

A kind of aramid fiber and reinforced plastic technology, applied in the field of all-dielectric indoor optical cable, can solve the problem that the tensile strength cannot be maximized and utilized, restrict the development process of flat shaped special-shaped indoor optical cable, and the aramid yarn is not easy to the outer sheath of the optical cable. problems such as tight integration, to achieve the effect of small size, compact structure and stable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] A preparation process of an aramid fiber reinforced plastic reinforcement adopts a pultrusion molding process, and the preparation process is as follows:

[0039] Step 1: Use O 2 The plasma is used to modify the aramid yarn. The equipment is an atmospheric pressure low-temperature plasma treatment device, the current frequency is 15KHz-20KHz, the voltage is 3KV, and the gas flow rate is 2L / min;

[0040] The second step: enter the solution tank and impregnate the vinyl resin;

[0041] Step 3: Enter the mold, form in the mold and heat and cure completely to obtain aramid fiber reinforced plastic. The temperature in the mold curing area is 200°C, the temperature in the shaping area is 140°C, and the curing traction speed is 6m / min;

[0042] Step 4: Preheat the fiber-reinforced plastic, and the preheating temperature is 320°C;

[0043] Step 5: After preheating, enter the extrusion mold for coating, and the coating traction speed is 450m / min;

[0044] Step 6: Rapid coolin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com