Thick core optical fibre laser welder and welding method

A welder and core fiber technology, applied in lasers, laser parts, phonon exciters, etc., to achieve the effects of precise heating power control, simple structure, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the scope of the present invention should not be limited thereto.

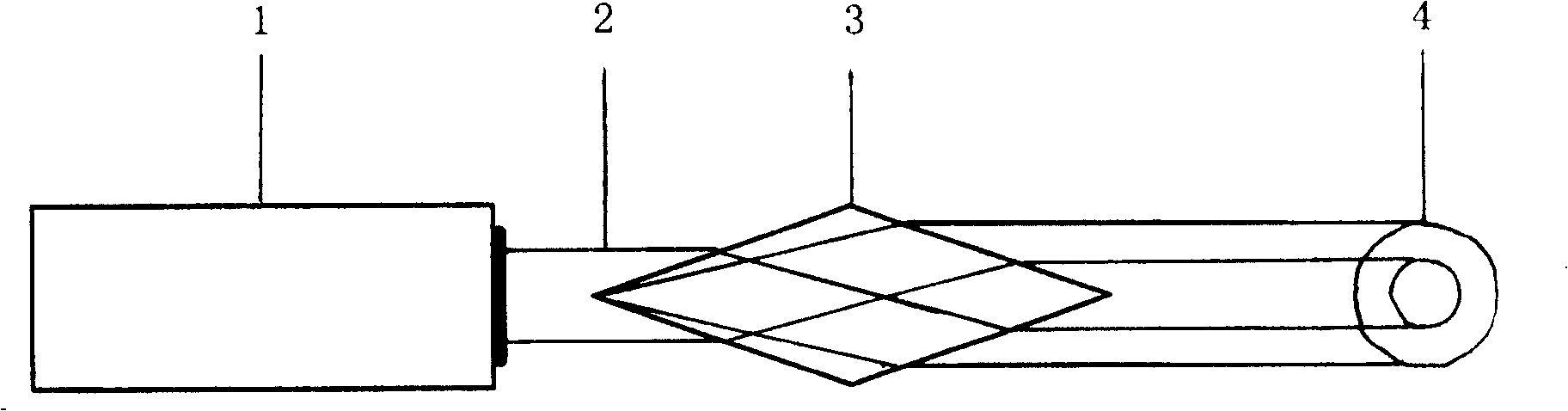

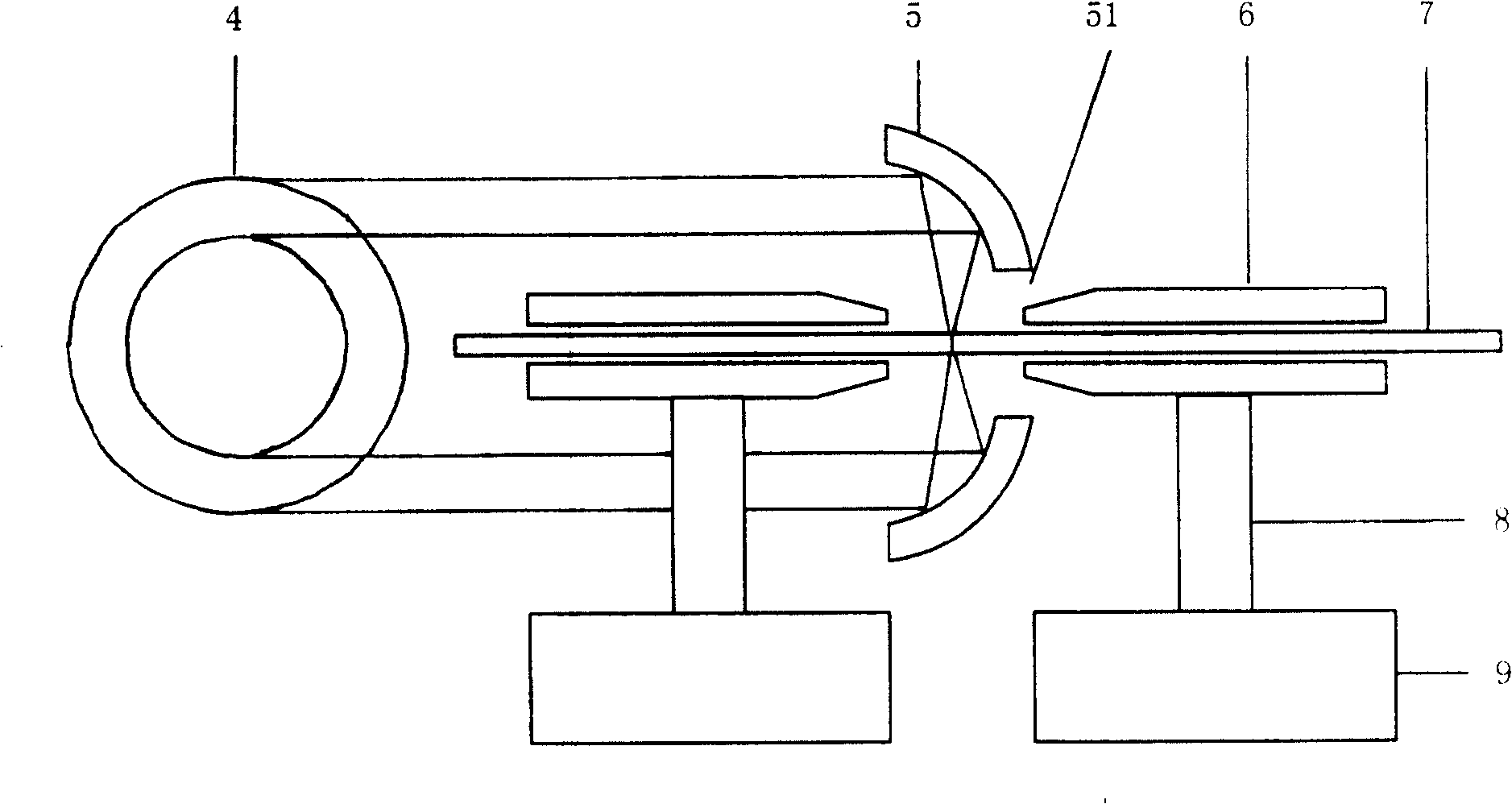

[0022] see figure 1 with figure 2 As shown, it can be seen from the figure that the thick-core fiber laser welder of the present invention includes a CO 2 Laser 1, where the CO 2 The forward direction of the output beam 2 of the laser 1 is provided with a jujube-shaped biconical lens 3 and a bowl-shaped reflective focusing mirror 5 with a circular hole 51 in the center of the bowl bottom. Two optical fiber clamps 6 clamp two sections of optical fibers 7 to be welded. The support 8 of the fiber clamp 6 is placed on the three-dimensional mobile device 9, and the CO 2 The laser beam 2 output by the laser 1 is irradiated on the bowl-shaped reflective focusing mirror 5 by the said date-shaped biconical lens 3 to shape the annularly distributed laser beam 4, and is focused on the bowl-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com