Device for processing cold internal hole of tube blanks

A processing device and hole processing technology, applied in the field of mechanical devices, can solve problems such as low production efficiency, and achieve the effects of compact equipment, good processing consistency, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

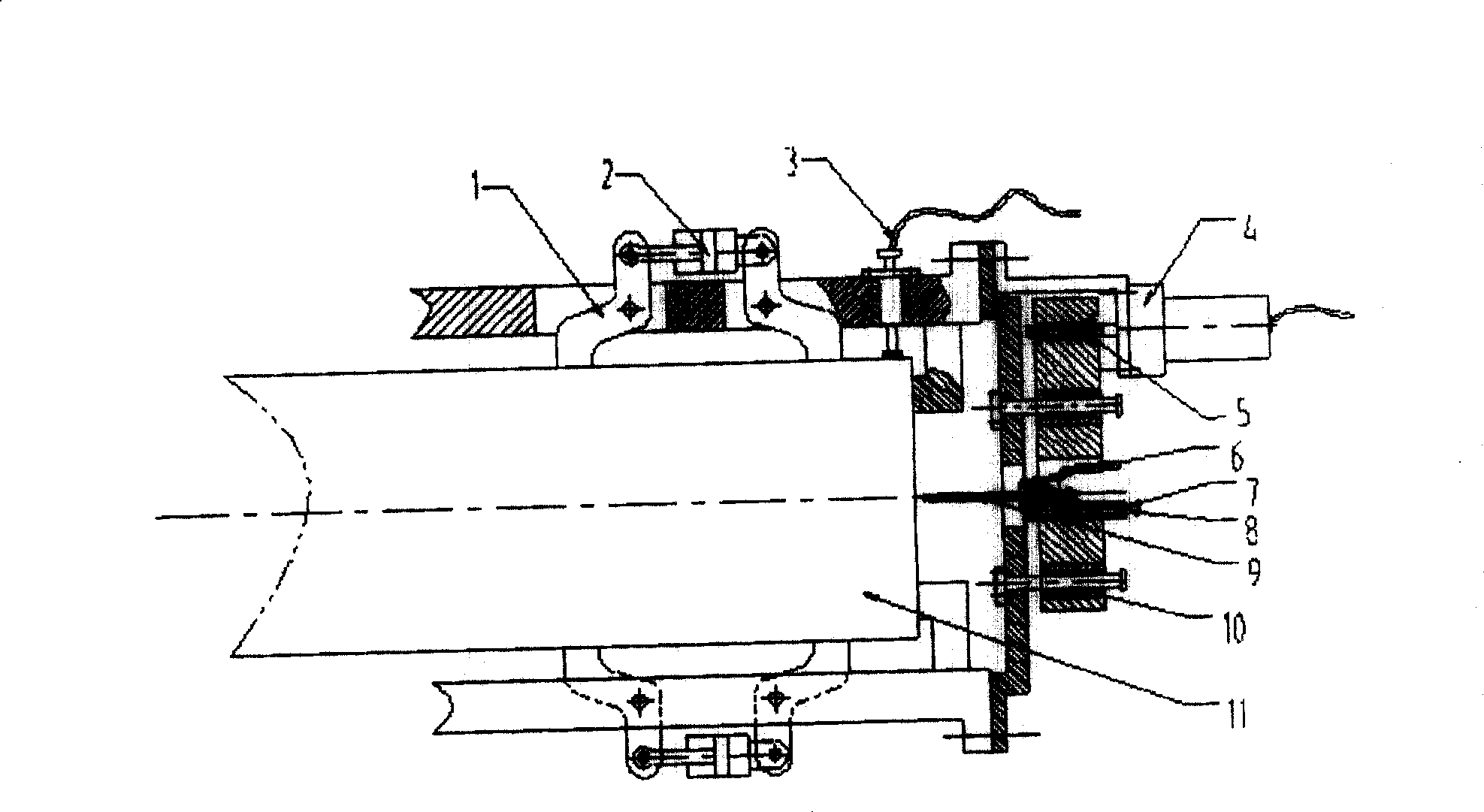

[0010] Example: This tube blank cold centering hole processing device includes a clamp 1 that controls and clamps the tube blank 11 through a cylinder 2; a carbon rod 9 that generates an arc with the tube blank 11; a cathode power source 3 that makes the tube blank 11 carry a negative electrode ; The anode power supply 7 with the positive electrode of the carbon rod 9; The cathode power source 3 is connected to the tube blank 11 through a copper rod. The feeding mechanism includes a servo motor 4 , a screw rod 5 and a guide rail 10 .

[0011] The function of the clamp 1 driven by the cylinder is to fix the carbon arc gas cutting equipment on the tube blank 11 to be processed, and to align the carbon rod 9 with the center of the processing surface of the tube blank. According to the size of the tube blank 11, the alignment of the carbon rod 9 can be adjusted by changing the collet.

[0012] The copper rods add electrodes to the tube blank 11 so as to generate an electric arc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com