Longitudinal inductor and scanning quenching technology for stepped axle longitudinal inductor

A technology of inductors and stepped shafts, which is applied in the field of scanning quenching process of longitudinal guide sensors and stepped shaft longitudinal guide sensors, can solve the problems of high cost and complicated process, and achieve the improvement of utilization rate, production efficiency and equipment cost economy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

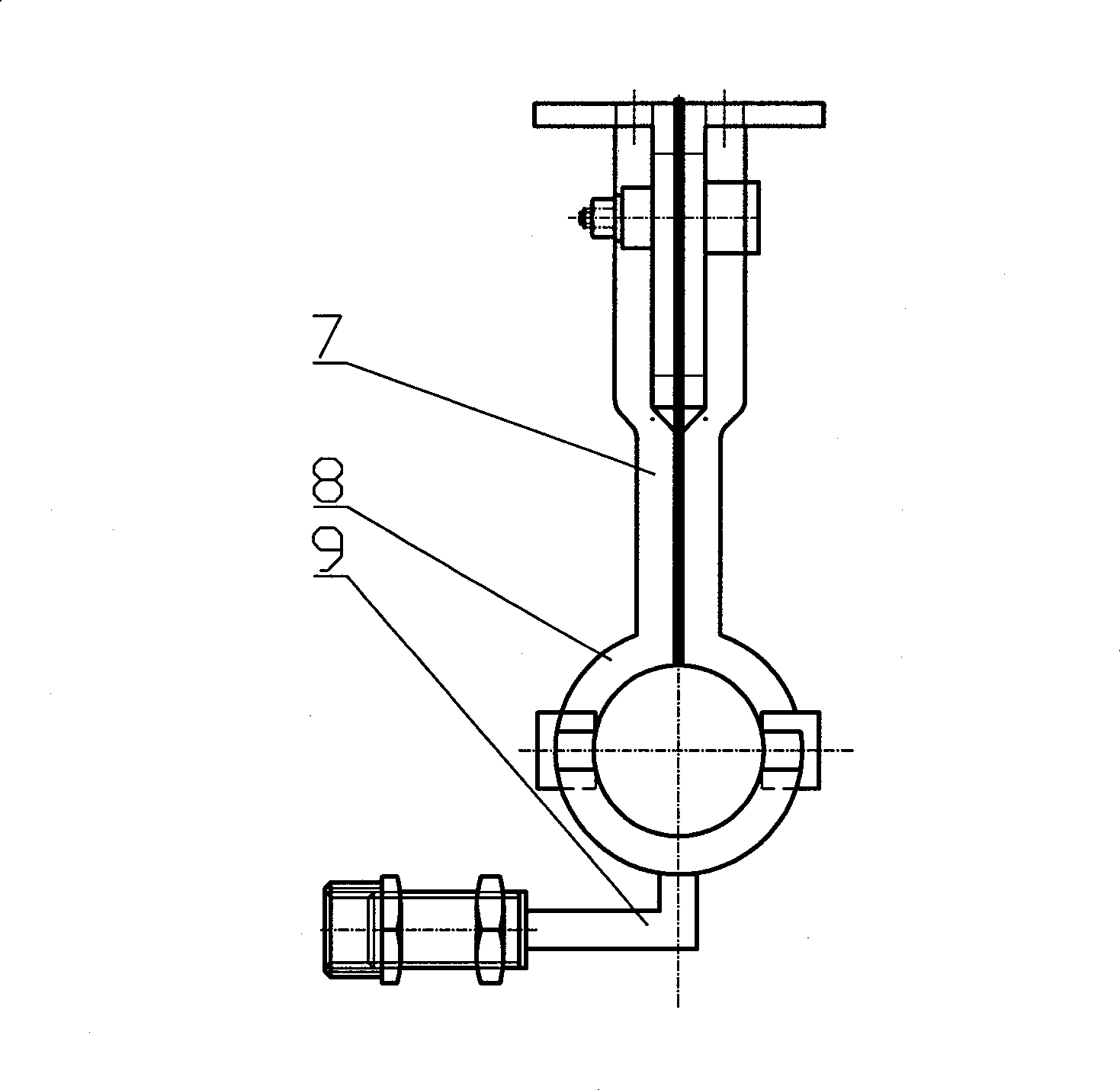

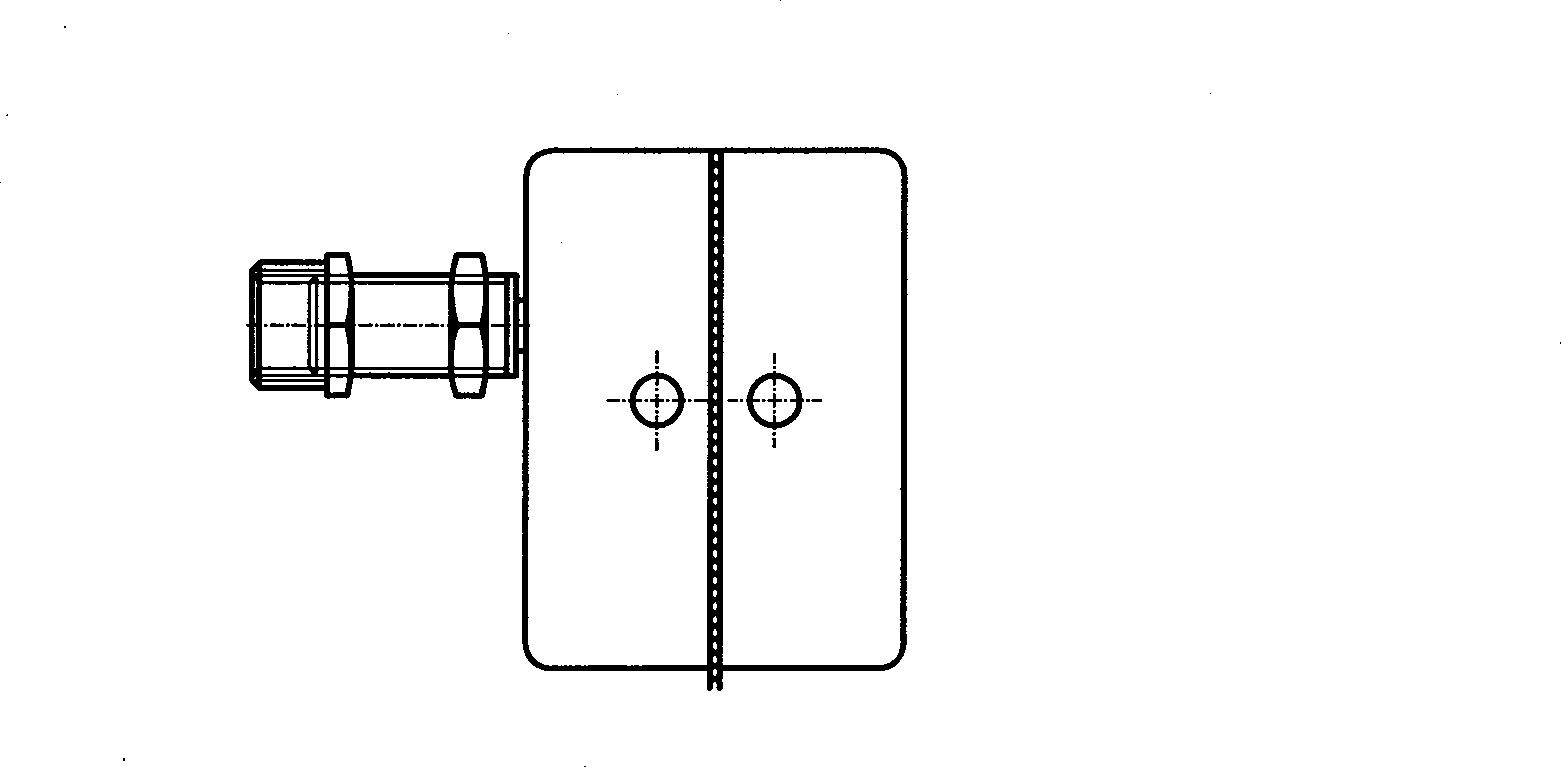

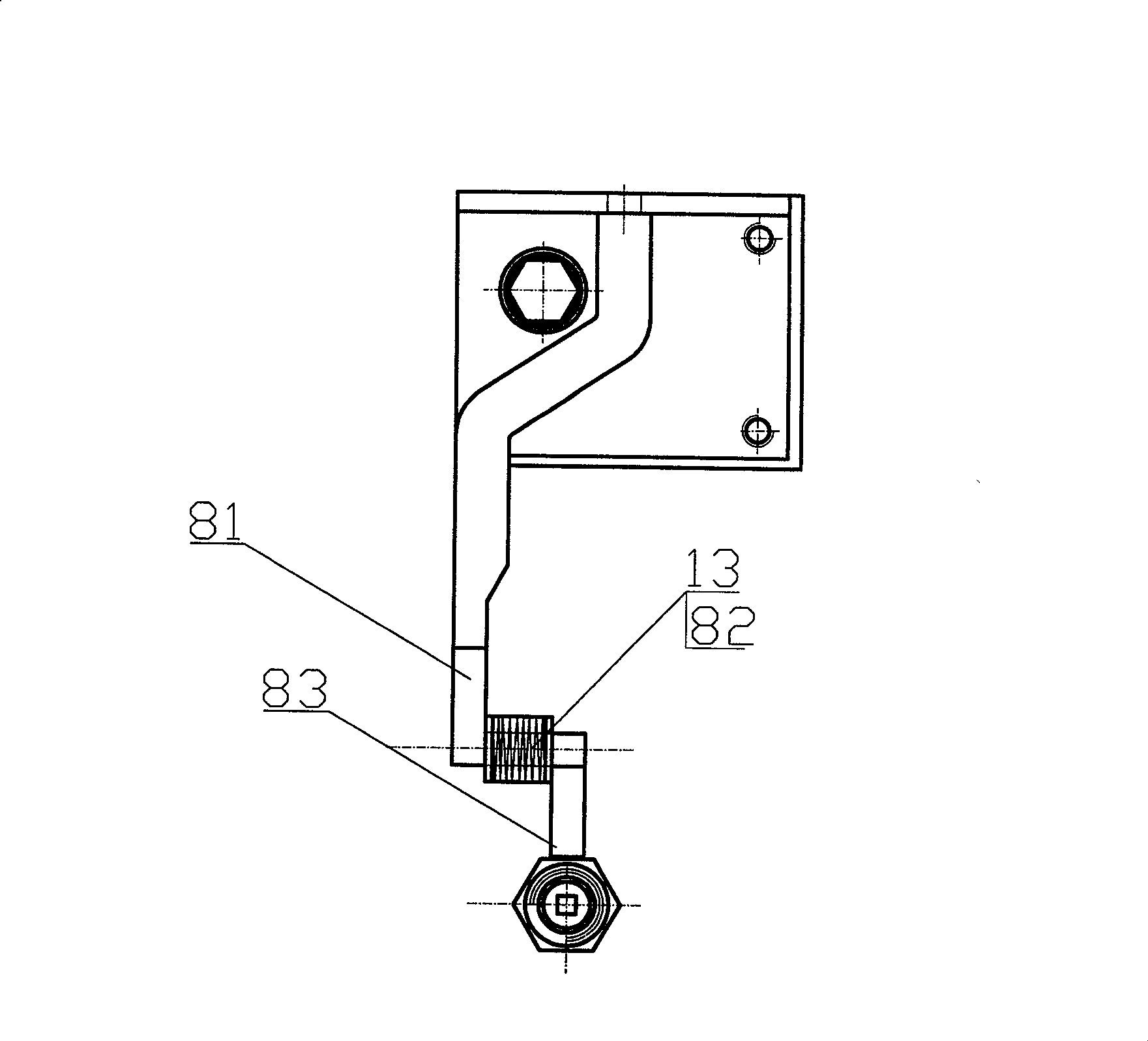

[0022] Longitudinal sensor: as attached Figure 1-3 As shown, it includes a coil body 8 connected to the lifting mechanism and connected to the intermediate frequency induction power supply through a power line, and a high-flux silicon steel sheet 13 fixed on the coil body. The coil body 8 is bent from a copper tube. Body 81, lower semicircular coil body 83 and two sections of straight pipe coil body 82 connected with upper semicircular coil body 81 and lower semicircular coil body 83 form an approximately closed space, and the stepped shaft passes through upper semicircular coil body 81 and lower semicircular coil body 81. The space formed by the semicircle coil body 83; the straight tube coil body 82 is perpendicular to the plane where the upper semicircle coil body 81 and the lower semicircle coil body 83 are located, and the straight tube coil body 82 is fixed with a U-shaped high-flux silicon steel sheet 13, U The open end of shaped high-flux silicon steel sheet 13 is clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com