Multi-tube pass type heat exchanger

A heat exchanger and multi-tube technology, applied in heat exchange equipment, heat exchanger types, indirect heat exchangers, etc., can solve problems such as low heat exchange efficiency, high manufacturing cost, and complex heat exchanger structure, and achieve Enhance heat transfer, save manufacturing costs, and improve the effect of emission performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

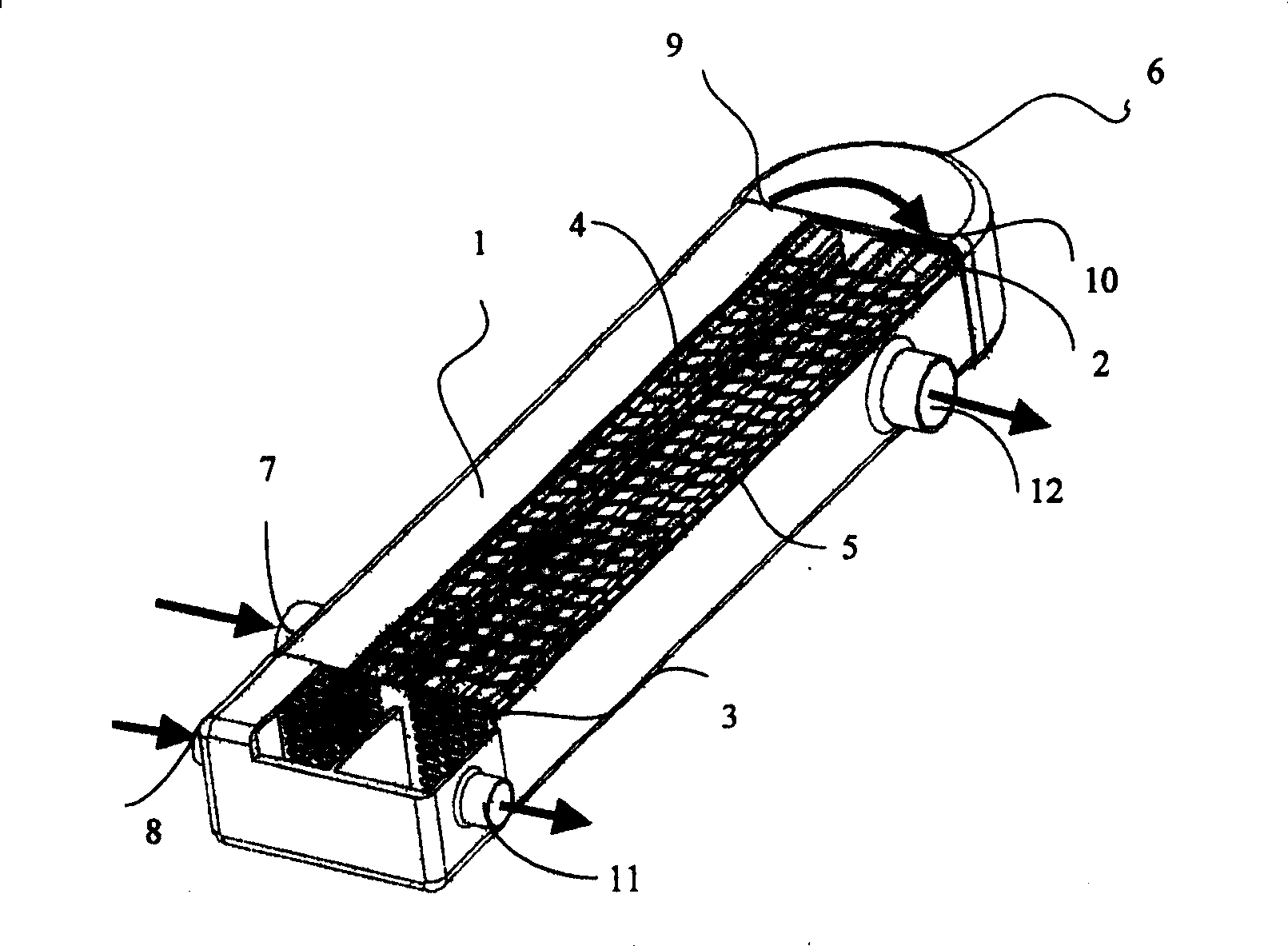

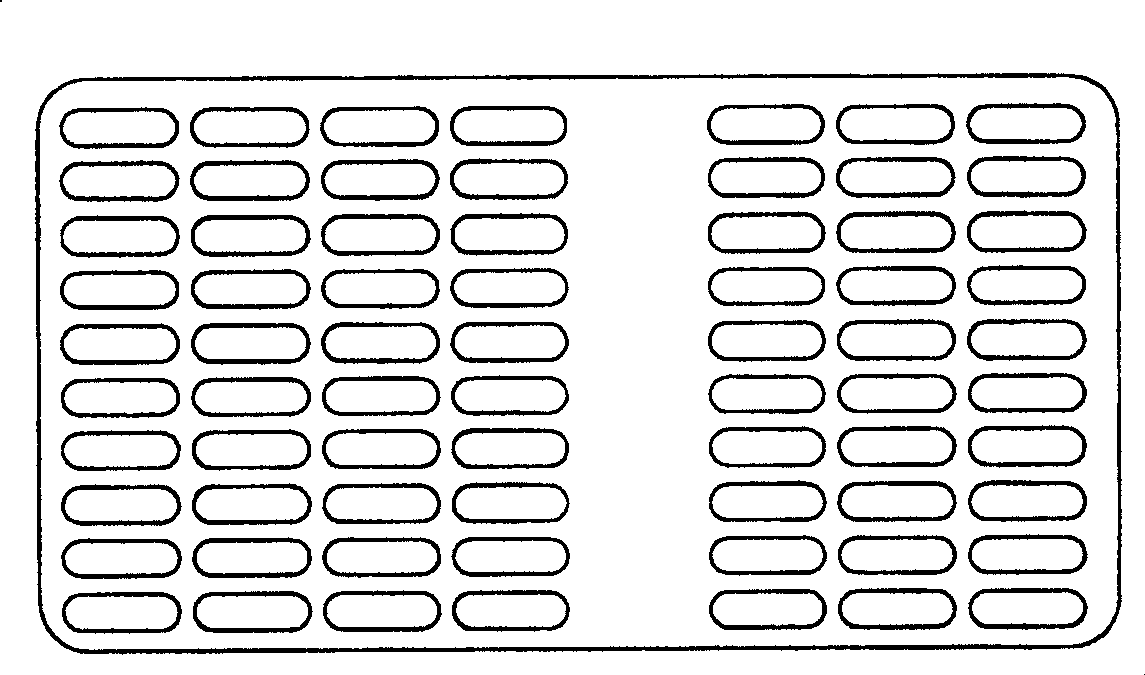

[0037] see figure 1 and figure 2 , is an embodiment in which the heat exchange tubes are divided into two tubes, wherein a fixed tube plate 3 is provided at both ends of the shell 1, and a fixed through hole for the heat exchange tube 2 is opened on the tube plate 3, and the heat exchange tube The nozzle ends of 2 are respectively welded in the corresponding holes on the tube sheet 3, and fixed in the shell 1 parallel to each other.

[0038] The heat exchange tubes 2 form the first tube pass 4 and the second tube pass 5, the exhaust gas outlet port of the engine is connected with the exhaust gas inlet port 8 of the first tube pass 4, the exhaust gas outlet port 9 of the first tube pass 4 is connected with the second tube pass The exhaust gas inlet port 10 of 5 is interconnected through the head 6 fixed on the casing 1, and the exhaust gas outlet port 11 of the second tube pass 5 is connected with the engine air inlet. The sealing head 6 has an arc-shaped curved surface to f...

Embodiment 2

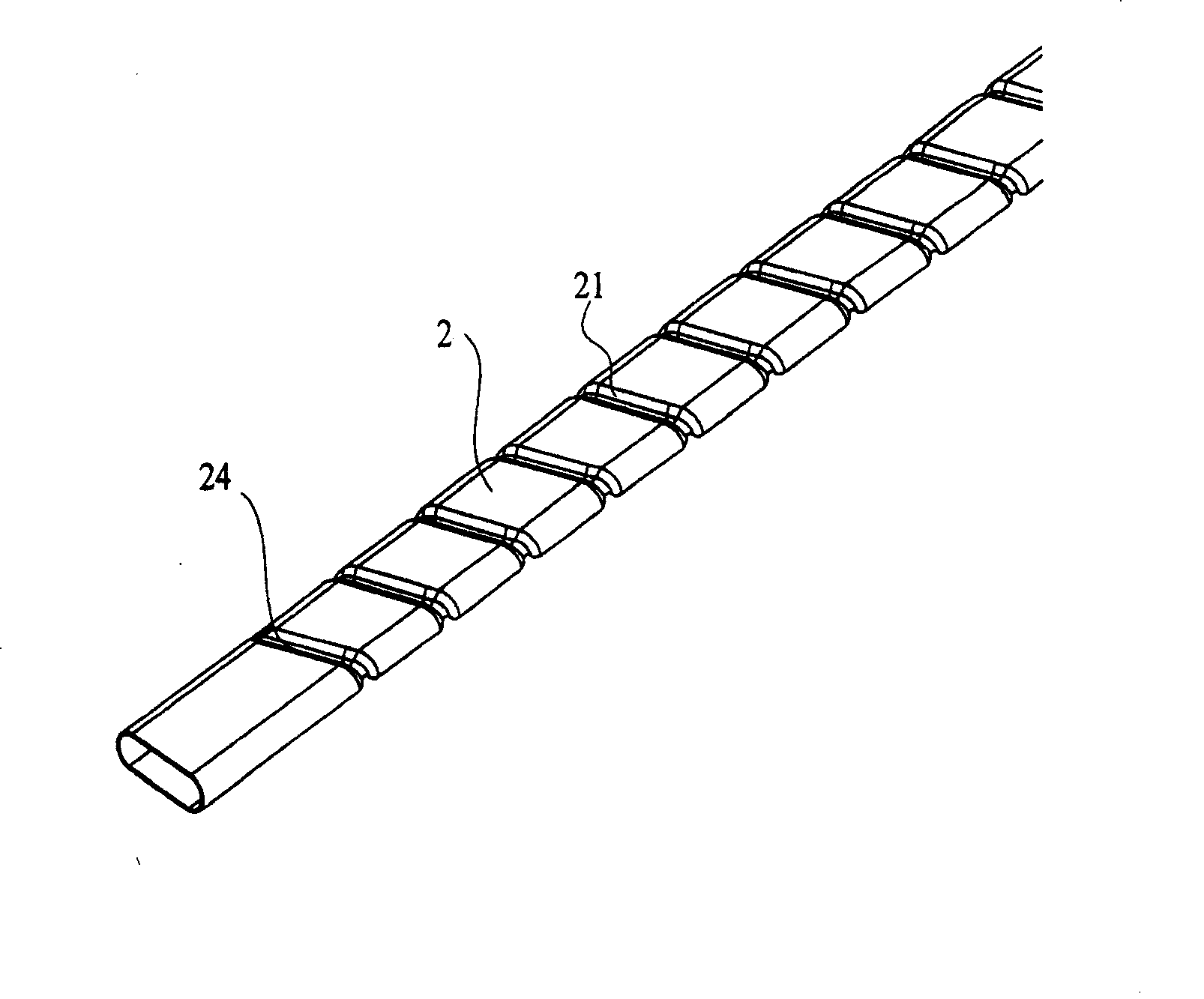

[0048] see figure 1 and Figure 4 , the fixed heat exchange tube 2 in the shell 1 is Figure 4 For the heat exchange tube with the first cross-sectional shape shown, the cross-section of the heat exchange tube 2 is flat, the two relatively long sides 23 are straight lines, and the two opposite short sides 22 are arc-shaped convex from the inside to the outside, and are in line with the The long side 23 is an arc-shaped transition connection, which makes full use of the surface of the heat exchange tube to achieve heat exchange with maximum efficiency, and is easy to produce and process.

Embodiment 3

[0050] see figure 1 and Figure 5 , the fixed heat exchange tube 2 in the shell 1 is Figure 5 For the heat exchange tube with the second cross-sectional shape shown, the cross-sectional shape of the heat exchange tube 2 is approximately rectangular, and a circular arc-shaped transition connection is set between the adjacent two sides; such a setting is convenient for production and processing, and can also improve the heat exchange tube. heat transfer efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com