V type coupling cavity wavelength switchable semiconductor laser

A technology of lasers and semiconductors, applied in the structure of semiconductor lasers, optical waveguide semiconductors, lasers, etc., can solve the problems of poor single-mode selection performance, and achieve the effect of low cost and high side mode suppression ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below according to the drawings and embodiments.

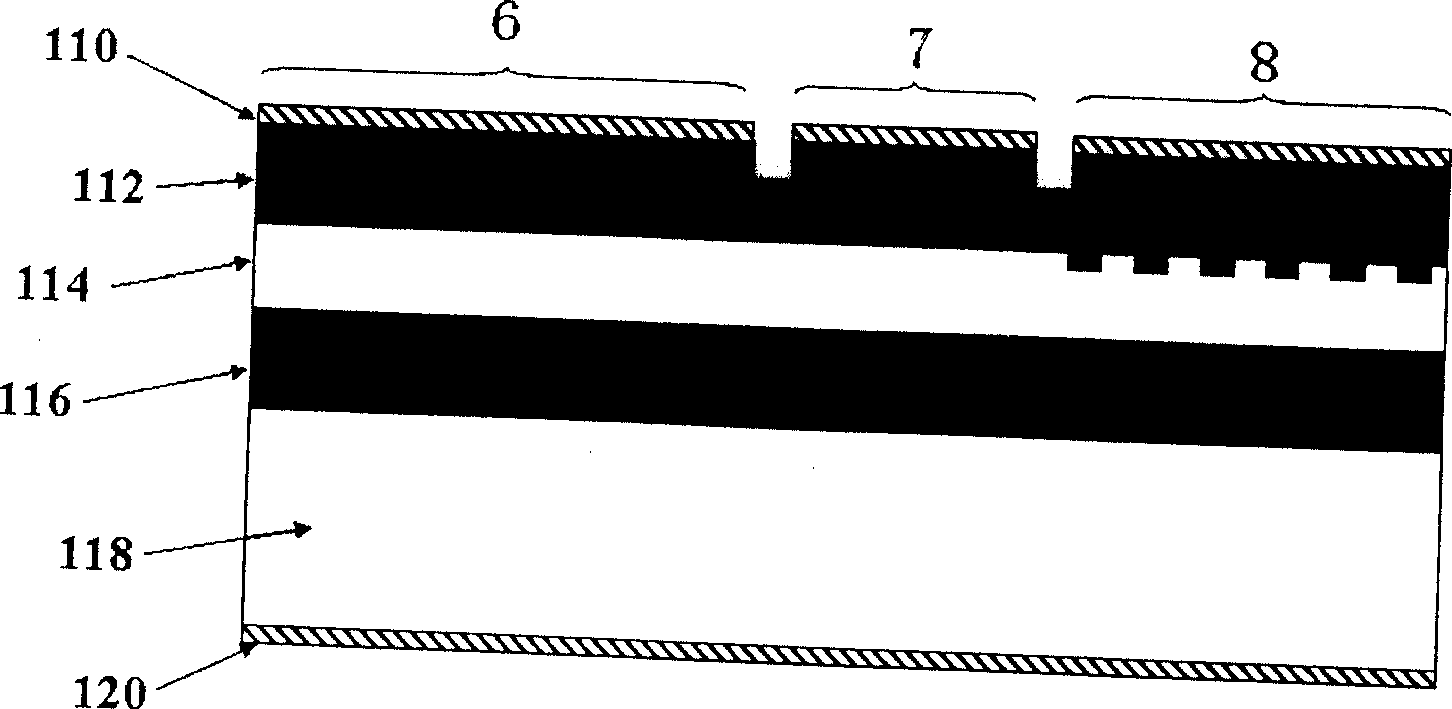

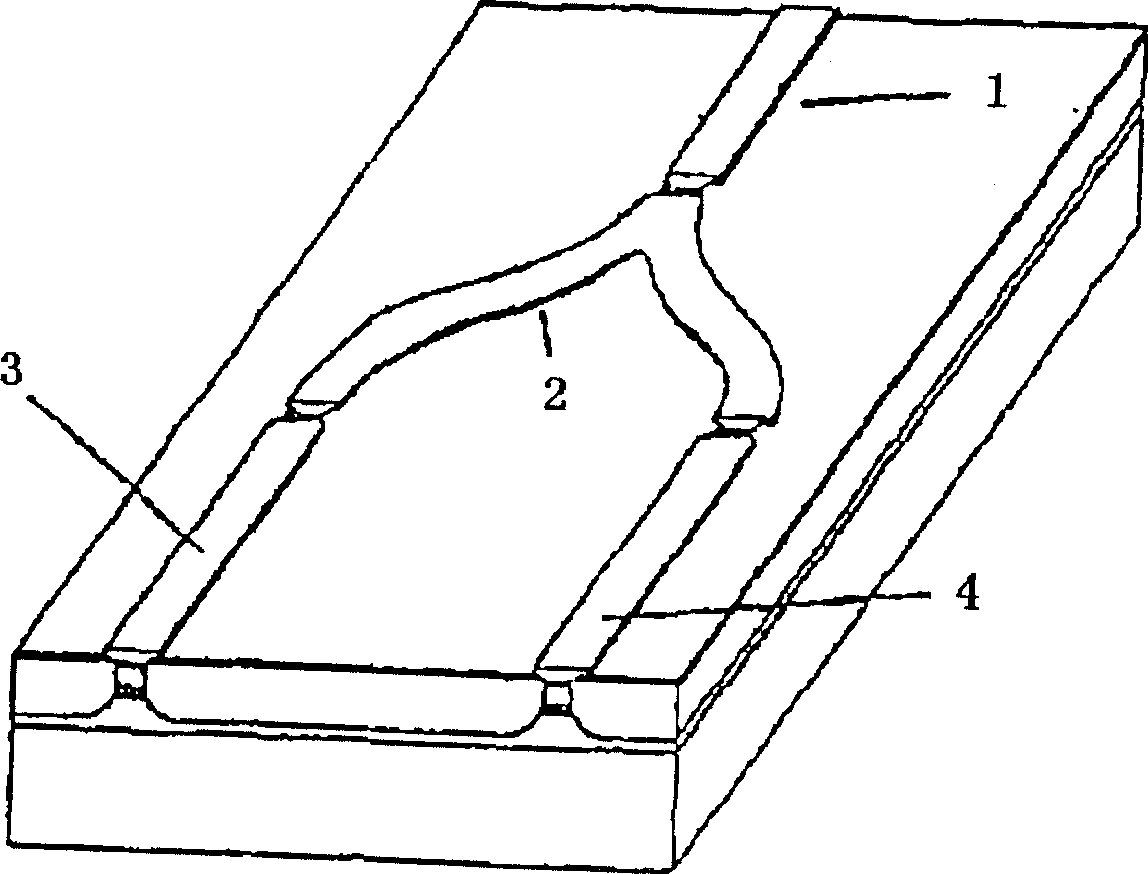

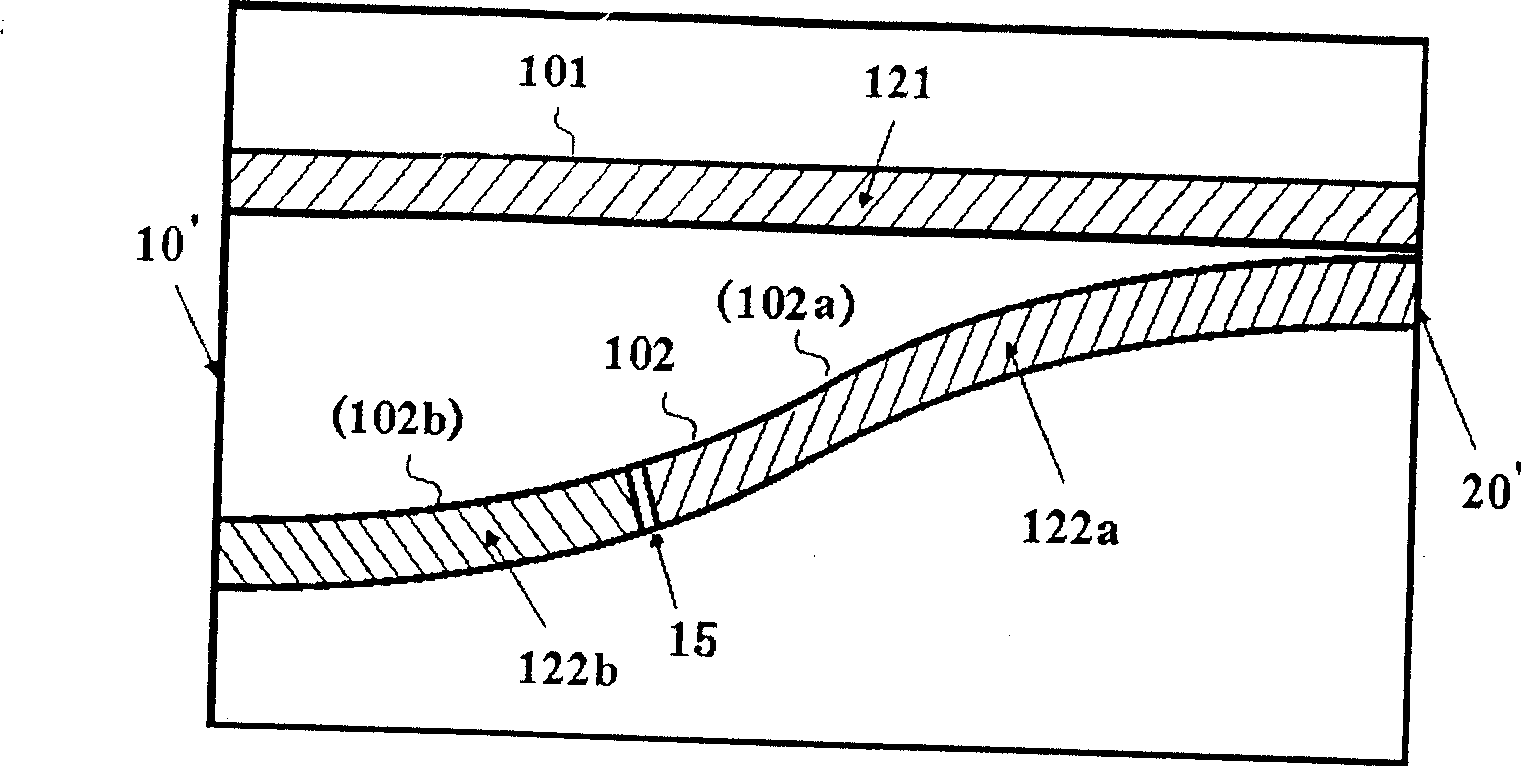

[0049] image 3 It is a schematic diagram of the first embodiment of the monolithic integrated wavelength variable V-coupled cavity laser of the present invention, which includes two optical waveguide arms (respectively optical waveguides 101 and 102 in the figure), arranged side by side on the semiconductor chip Make a V shape. The two optical waveguides are close together at one end (closed end), but far apart at the other end (open end). There is a reflective element at both ends of each optical waveguide, which can be a cleavage reflective surface (respectively image 3 The end face 10' and the end face 20') or rectangular deeply etched grooves (such as 10 and 20 in Figures 14, 16, 17 and 18). Each optical waveguide and the reflective elements at its ends form a Fabry-Perot cavity. Near the end face 20', because the two waveguides are very close or in contact, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com