Cleaning foam fluid for fault detection and a preparation method thereof

A technology for penetrating flaw detection and cleaning liquid, which is applied in chemical instruments and methods, detergent materials, detergent compounding agents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

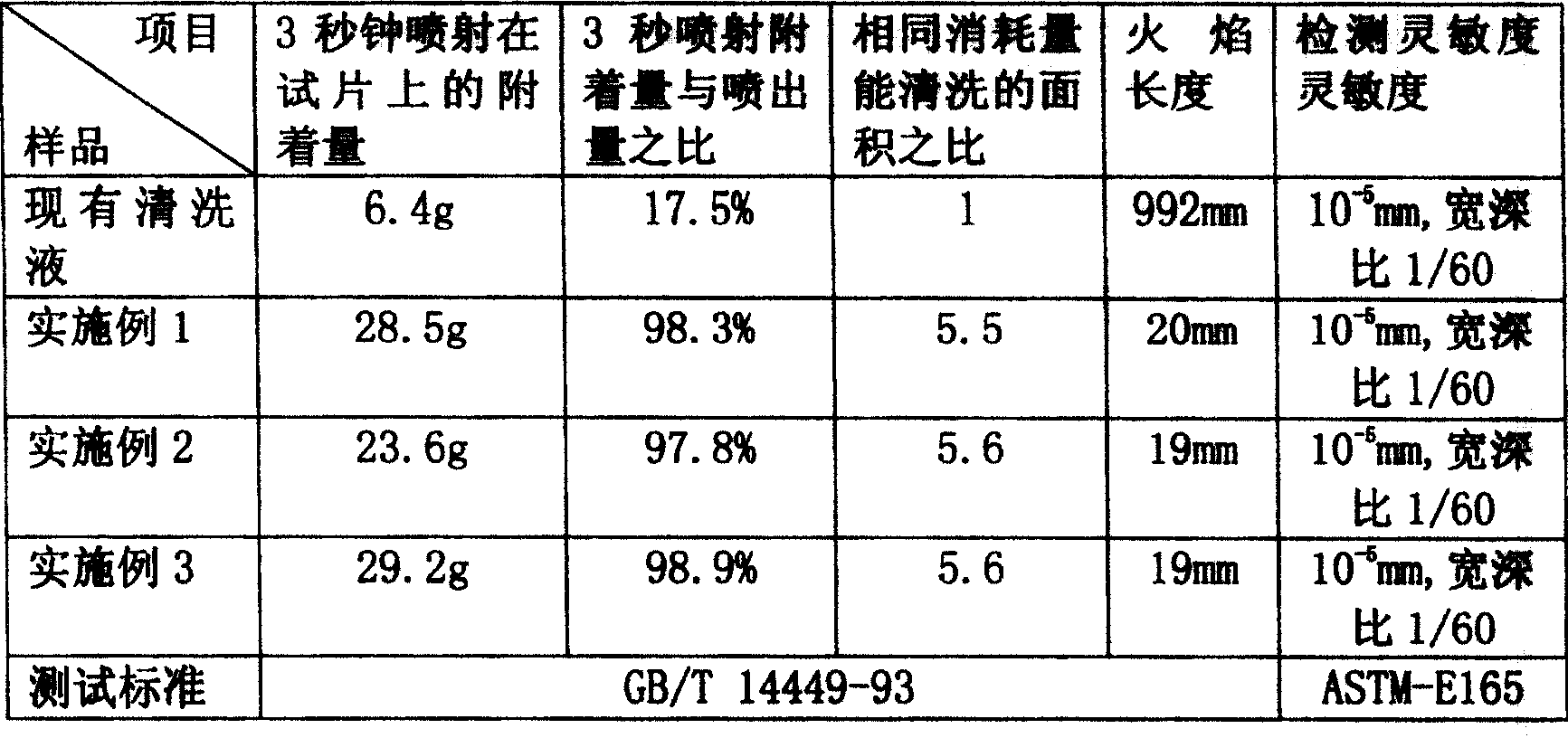

Examples

Embodiment 1

[0054] Example 1 The composition ratio of the foam-type penetrant flaw detection cleaning solution is as follows:

[0055] Composition wt%

[0056] Existing cleaning solution 80

[0057] Precipitated Magnesium Aluminum Silicate 10

[0058] Polyvinyl acetal 6

[0059] Potassium Acylsarcosinates 4

[0060] Wherein the composition ratio of existing cleaning solution is as follows:

[0061] Composition wt%

[0062] denatured alcohol 45

[0063] Ethylene glycol monobutyl ether 18

[0064] Propanol 12

[0065] Hydrogenated kerosene 18

[0066] Fatty alcohol polyoxyethylene ether 3

[0067] Alkylbenzenesulfonic acid 4

[0068] Its preparation steps are as follows:

[0069] ① Use industrially pure raw materials;

[0070] ② Prepare the required amount of existing cleaning solution according to the composition ratio of the existing cleaning solution;

[0071] ③ Weigh each raw material according to the ratio of the selected foam-type coloring flaw detection cleaning solution...

Embodiment 2

[0078] Example 2 The composition ratio of the foam type penetrant flaw detection cleaning solution is as follows:

[0079] Composition wt%

[0080] Existing cleaning solution 50

[0081] Precipitated Magnesium Aluminum Silicate 30

[0082] Polyvinyl acetal 12

[0083] Potassium Acylsarcosine 8

Embodiment 3

[0084] Embodiment 3 The proportioning of the ingredients of the foam type penetrant flaw detection cleaning solution is as follows:

[0085] Composition wt%

[0086] Existing cleaning solution 61

[0087] Precipitated Magnesium Aluminum Silicate 26

[0088] Polyvinyl acetal 8

[0089] Potassium Acylsarcosine 5

[0090] The preparation steps of embodiment 2 and embodiment 3 are the same as embodiment 1, and the proportioning of the existing cleaning agent selected is also the same, but the proportioning amount of each component is different during configuration, and the fifth step in embodiment 2 in the configuration process The beating time was 2.5 hours, and the stirring time of the 6th step was 3 hours; the beating time of the 5th step was 3 hours in the embodiment 3, and the stirring time of the 6th step was 3.5 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com