Ultrasonic auxiliary headspace liquid-phase microextraction method

An ultrasonic-assisted, headspace liquid technology, applied in the direction of solvent extraction of liquid solution, chemical/physical/physicochemical process of energy application, preparation of test samples, etc. Eliminate problems such as shedding, achieve the effects of shortening the equilibrium time, prolonging the extraction time, and increasing the extraction volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

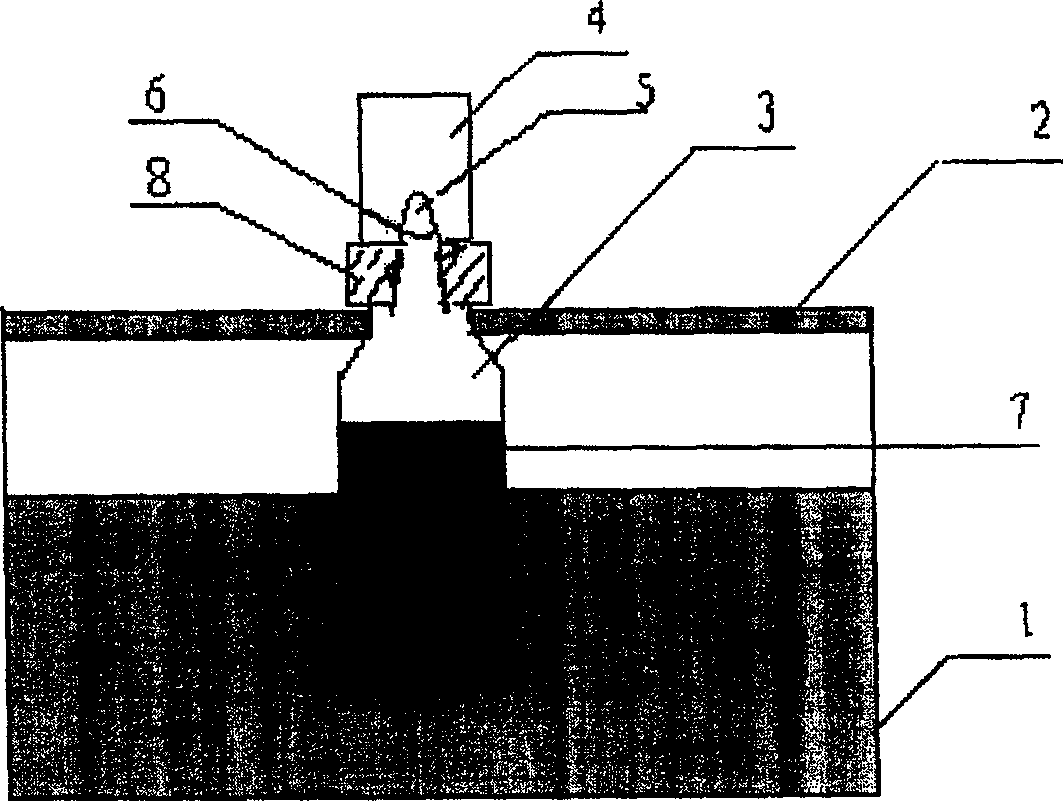

[0030] The example structure of the present invention is as figure 1 As shown, it consists of an ultrasonic cleaner 1 , a heat shield 2 , a 0.2 ml PCR tube 6 , a sample bottle 7 , a bottle stopper 8 ; and an ice bath 4 . The central part of the heat shield fixes the sample bottle, the lower part of the sample bottle is immersed in the ultrasonic cleaner water bath, and the bottom of the 0.2 ml PCR tube is filled with 20 microliters of extraction solution 5 . Insert the mouth of the PCR tube containing the extract upwards into the small hole of the bottle stopper 8 of the sample bottle 7, the bottle stopper 8 is inserted into the sample bottle 7 containing the sample and the bottom of the PCR tube 6 faces upwards, seal, and the sample bottle The upper part is placed in ice bath 4 together with the 0.2 ml PCR tube. Utilize the present invention to measure the chlorophenol in the water sample

[0031] Mix 10 mL of 1 μg / mL sample (2-chlorophenol, 2.4-dichlorophenol, 2.6-dichloro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com