Carriage assembly manufacturing method in welding production line

A technology of welding production line and welding trolley, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of adding auxiliary processes and frame deformation, so as to avoid frame deformation, ensure welding quality, and guarantee accessibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

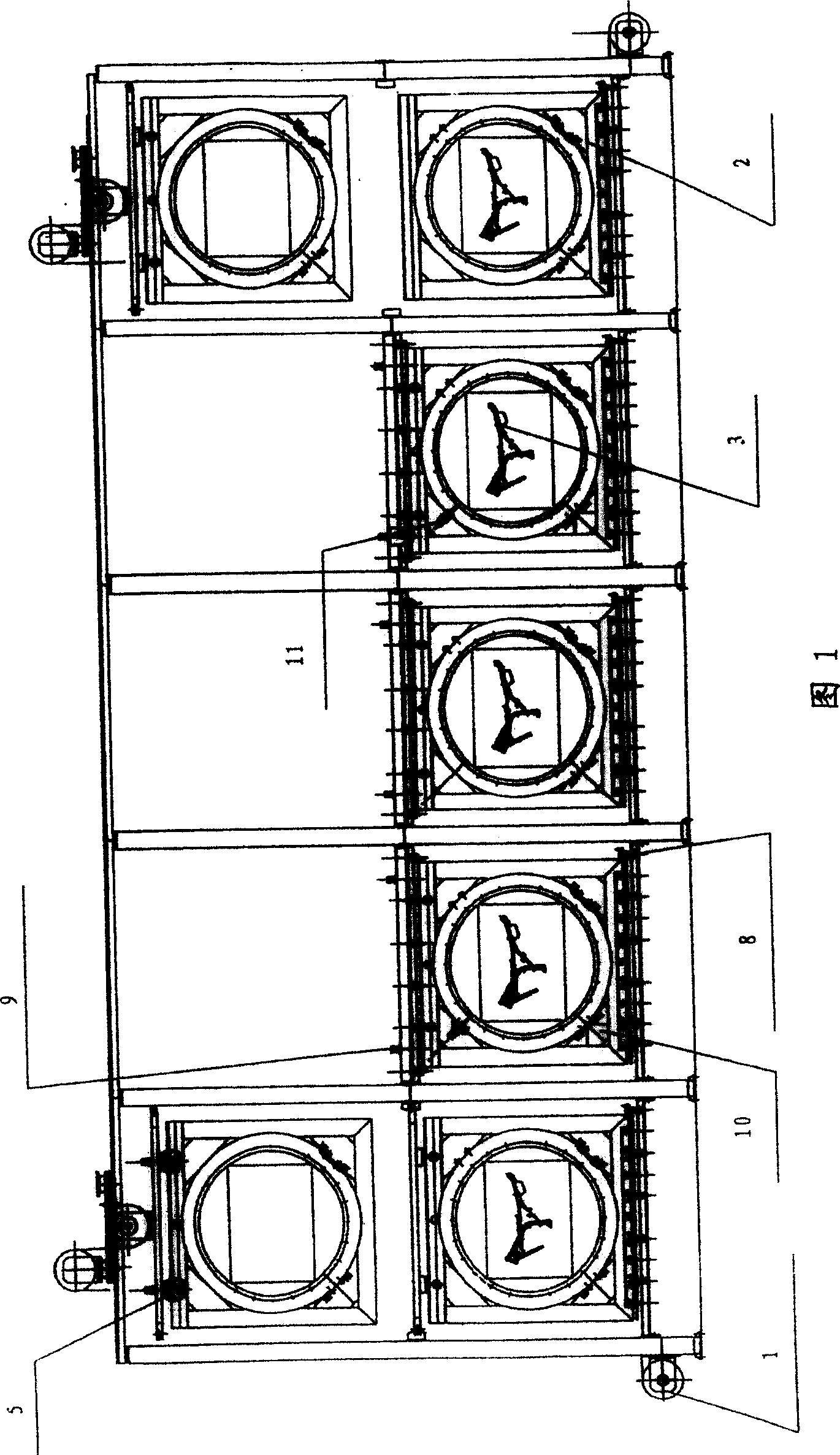

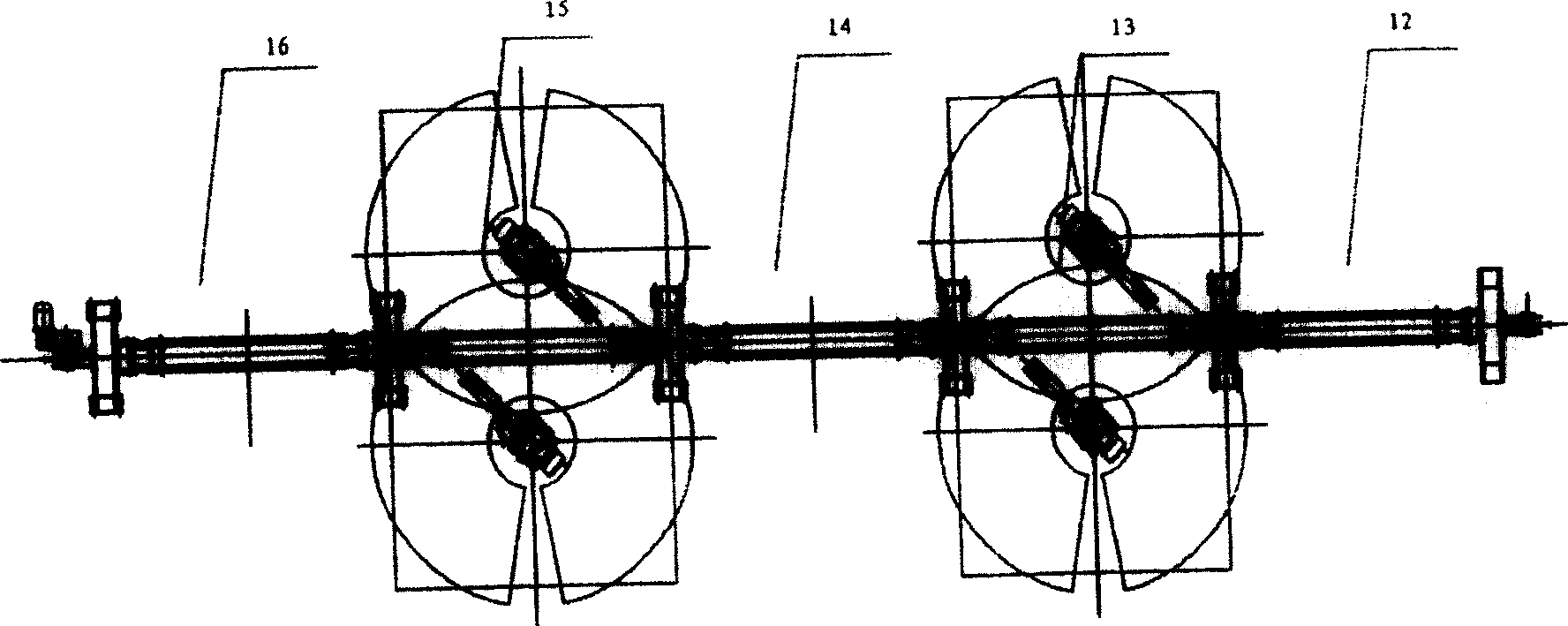

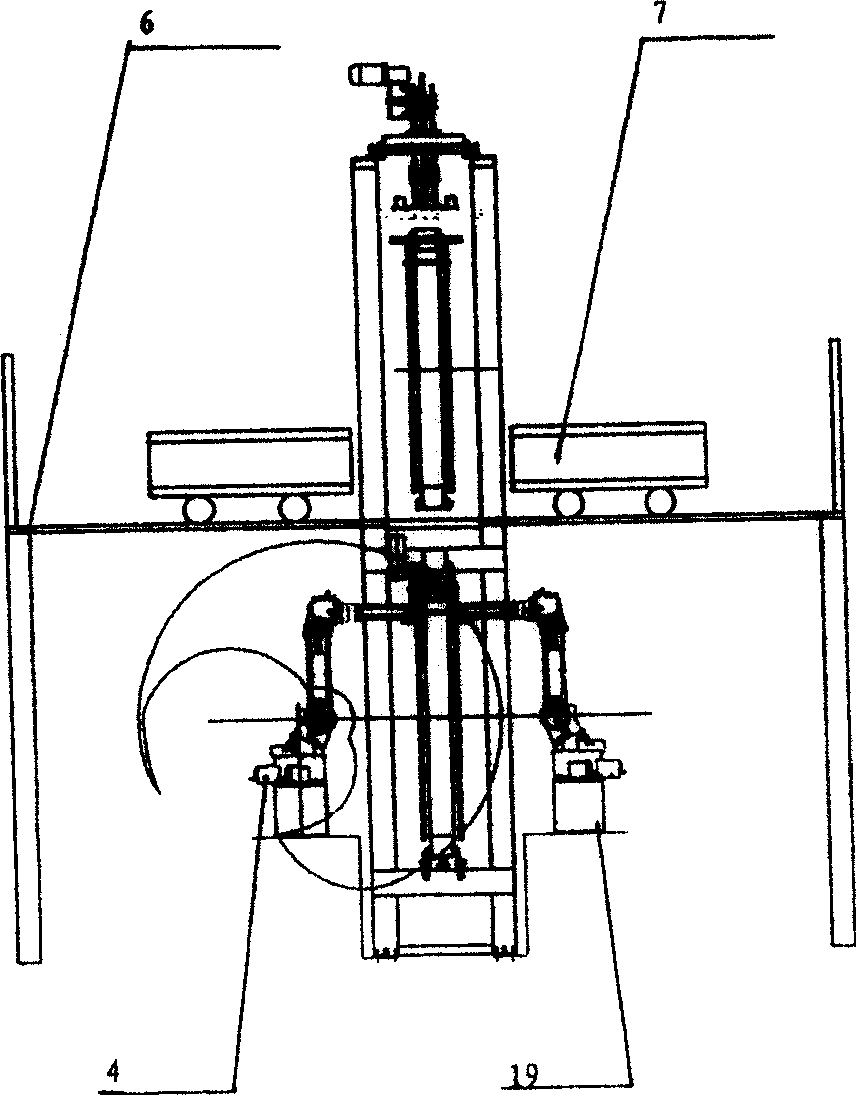

[0036] See Figure 1~ Figure 4 , the welding production line is equipped with five stations, which are respectively in order: assembling the frame parts 12, welding 13, assembling the rest of the accessory parts of the frame 14, welding 15, and finished product off-line 16, of which two welding stations use four welding Robot 4, performing symmetrical welding.

[0037] Main components: welding robot 4, welding trolley 2, welding fixture transmission line 1, lifting equipment 5, welding station stop device 8, fixture positioning and clamping mechanism 9, servo motor 10, coupling, fixture platform 6, fixture replacement trolley 7. There is also a control system. The welding trolley is composed of a large ring gear 17 with an inner diameter of 2500mm, bearings, RV reducer, frame, etc., and five stations are equipped with electric and pneumatic quick-plug interfaces.

[0038] work process:

[0039] 1. Assemble the frame frame parts station 12 to complete the assembly of the fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com