Mud phosphor recovery and refining method

A refining method and sludge phosphorus recovery technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of low phosphorus content, low yield of sludge phosphorus recovery, poor product color, etc., and achieve high phosphorus content , good chroma, reduce the effect of cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

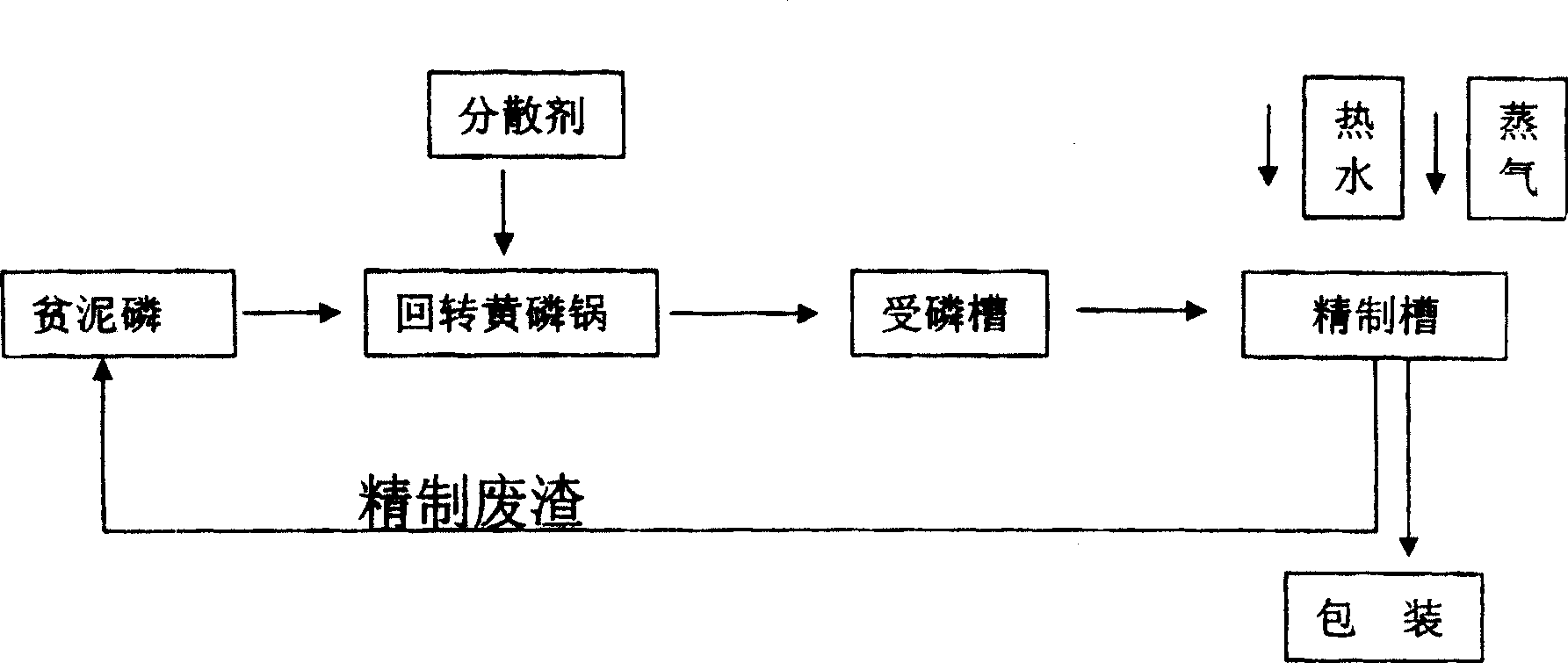

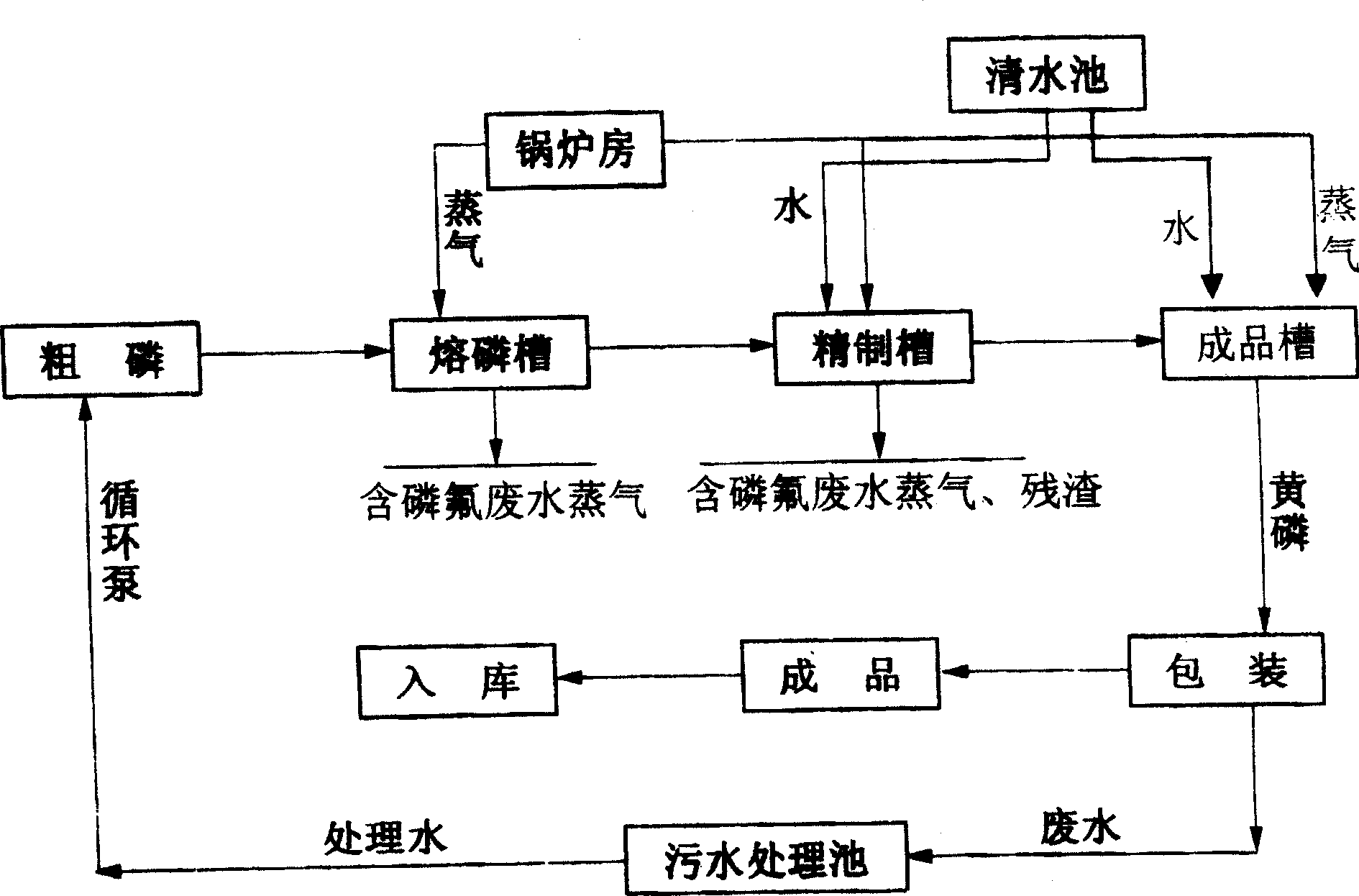

[0017] 1) Put the mud phosphorus into the rotary phosphorus steaming pot, the filling amount of the mud phosphorus accounts for 30% to 40% of the capacity of the rotary phosphorus steaming pot, add ammonium chloride with a weight of 2‰ of the mud phosphorus to the mud phosphorus, mix evenly, and start steaming , When steaming, the temperature in the furnace is 260℃~300℃, and the steaming time is 3 hours. After the elemental phosphorus is evaporated, it is collected in the phosphorus receiving tank. This is crude phosphorus, and the slag is removed after natural cooling for 2 hours. In this process, the heating furnace should be heated evenly to avoid the uneven temperature distribution leading to the agglomeration of sludge phosphorus and the conversion of yellow phosphorus into red phosphorus, which will affect the recovery rate and quality of phosphorus.

[0018] 2) Fill the water tank with water, input steam to heat the water to 60°C;

[0019] 3) Send the crude phosphorus c...

Embodiment 2

[0023] 1) Put the mud phosphorus into the rotary phosphorus steaming pot, the filling amount of the mud phosphorus accounts for 30% to 40% of the capacity of the rotary phosphorus steaming pot, add ammonium chloride with a weight of 5‰ of the mud phosphorus to the mud phosphorus, mix evenly, and start steaming , When steaming, the temperature in the furnace is 260℃~300℃, and the steaming time is 4 hours. After the elemental phosphorus is evaporated, it is collected in the phosphorus receiving tank. This is crude phosphorus, and the slag is removed after natural cooling for 2 hours. In this process, the heating furnace should be heated evenly to avoid the uneven temperature distribution leading to the agglomeration of sludge phosphorus and the conversion of yellow phosphorus into red phosphorus, which will affect the recovery rate and quality of phosphorus.

[0024] 2) Fill the water tank with water, input steam to heat the water to 75°C for later use;

[0025] 3) Send the crud...

Embodiment 3

[0029] 1) Put the mud phosphorus into the rotary phosphorus steaming pot, the filling amount of the mud phosphorus accounts for 30% to 40% of the capacity of the rotary phosphorus steaming pot, add diatomite with a weight of 4‰ of the mud phosphorus to the mud phosphorus, mix evenly, and start steaming , The temperature in the furnace is 260°C to 300°C during steaming, and the steaming time is 3.5 hours. After the elemental phosphorus is evaporated, it is collected in the phosphorus receiving tank. This is crude phosphorus, and the slag is removed after natural cooling for 2 hours. In this process, the heating furnace should be heated evenly to avoid the uneven temperature distribution leading to the agglomeration of sludge phosphorus and the conversion of yellow phosphorus into red phosphorus, which will affect the recovery rate and quality of phosphorus.

[0030] 2) Fill the water tank with water, input steam to heat the water to 70°C for later use;

[0031] 3) Send the crud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com