Method for processing commutator strengthening ring

A processing method and technology of reinforcing rings, which are applied in the field of plastic molding processing, can solve the problems of unsatisfactory tensile strength and high temperature resistance, increased waste of materials and energy, and high scrap rate of finished products, so as to improve mechanical properties, reduce scrap rate, The effect of improving high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

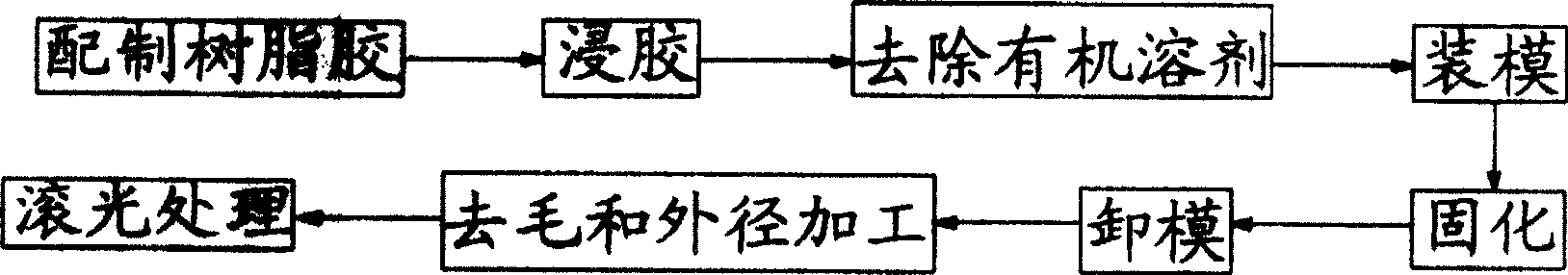

[0034] Embodiment 1, reference figure 1 .

[0035] The processing method of the commutator reinforcement ring in the present embodiment comprises the following steps:

[0036] ①Preparation of resin glue: Weigh 1 part by weight of E51 epoxy resin, 1 part by weight of phenolic resin, and 1 part by weight of organic solvent. The number is 0.06, and the aforementioned raw materials are mixed evenly and then poured into the glue tank of the dipping machine;

[0037] ②Dipping: take the S-glass fiber yarn and pass through the glue tank equipped with resin glue in step ①, and the S-glass fiber yarn accounts for 75% of the total resin weight after being dipped, and this proportion is controlled by the speed of winding yarn;

[0038] ③ Removal of organic solvents: drying in an oven, the temperature of the oven is controlled at 80-150°C, and the time is controlled at 2-6 minutes;

[0039] ④ Mold loading: take the dried product and wind it on the bobbin, then make the product pass throug...

Embodiment 2

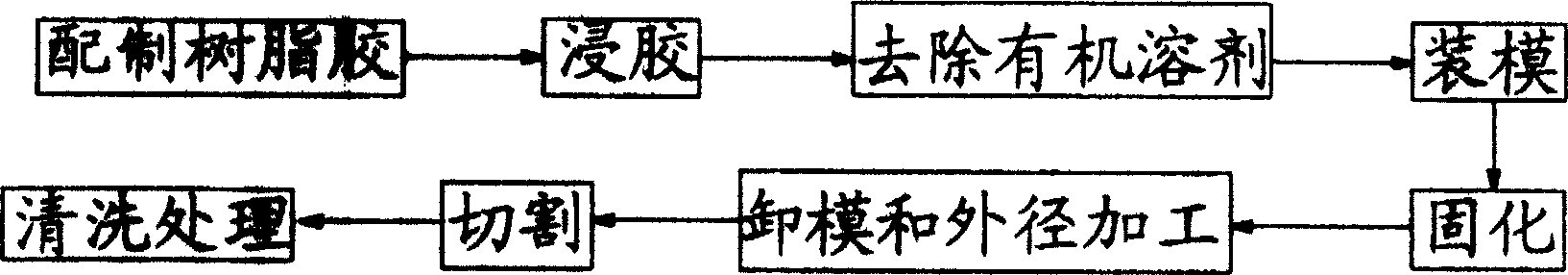

[0048] Embodiment 2, refer to figure 2 .

[0049] The processing method of the commutator reinforcement ring in the present embodiment comprises the following steps:

[0050] ① Preparation of resin glue: weigh E51 epoxy resin with a weight ratio of 1, phenolic resin with a weight ratio of 1, and organic solvent with a weight ratio of 3; mix the aforementioned raw materials evenly and pour them into the glue tank of the dipping machine;

[0051] ② dipping: take the S-glass fiber yarn and pass through the glue tank equipped with resin glue in step ①, and the S-glass fiber yarn accounts for 70% of the total resin weight after dipping;

[0052] ③ Removal of organic solvents: drying in an oven, the temperature of the oven is controlled at 50-150°C, and the time is controlled at 2-6 minutes;

[0053] ④ Mold loading: take the dried product and wind it on the bobbin, then make the product pass through the tension regulator, and wind the product on the mold rod with a winding machin...

Embodiment 3

[0060] The processing method of the commutator reinforcement ring in the present embodiment is characterized in that comprising the following steps:

[0061] ① Prepare resin glue: weigh E51 epoxy resin with a weight ratio of 0.7, phenolic resin with a weight ratio of 1.4, and an organic solvent with a weight ratio of 0.5. Mix the aforementioned raw materials evenly and pour them into the glue tank;

[0062] 2. Glue dipping: take the S-glass fiber yarn and pass through the glue tank equipped with resin glue in step ①, and the S-glass fiber yarn accounts for 80% of the total resin weight after dipping;

[0063] ③Remove the solvent and then pass through an oven for drying. The temperature of the oven is controlled at 50-150°C, and the time is controlled at 2-6 minutes.

[0064] ④Mould loading: take the dried product and wind it on the yarn bobbin, then make the product pass through the tension regulator, and wind the product on the metal rod with the winding machine;

[0065] ⑤ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com