Speed differential mechanism of winching grinder

A technology of differential mechanism and winch mill, applied in the direction of spring mechanism, hoisting device, etc., can solve the problem of aggravated deformation, fracture, machining accuracy, assembly process constraints, gear pin shaft 211 can not well reflect synergy, etc. problem to ensure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

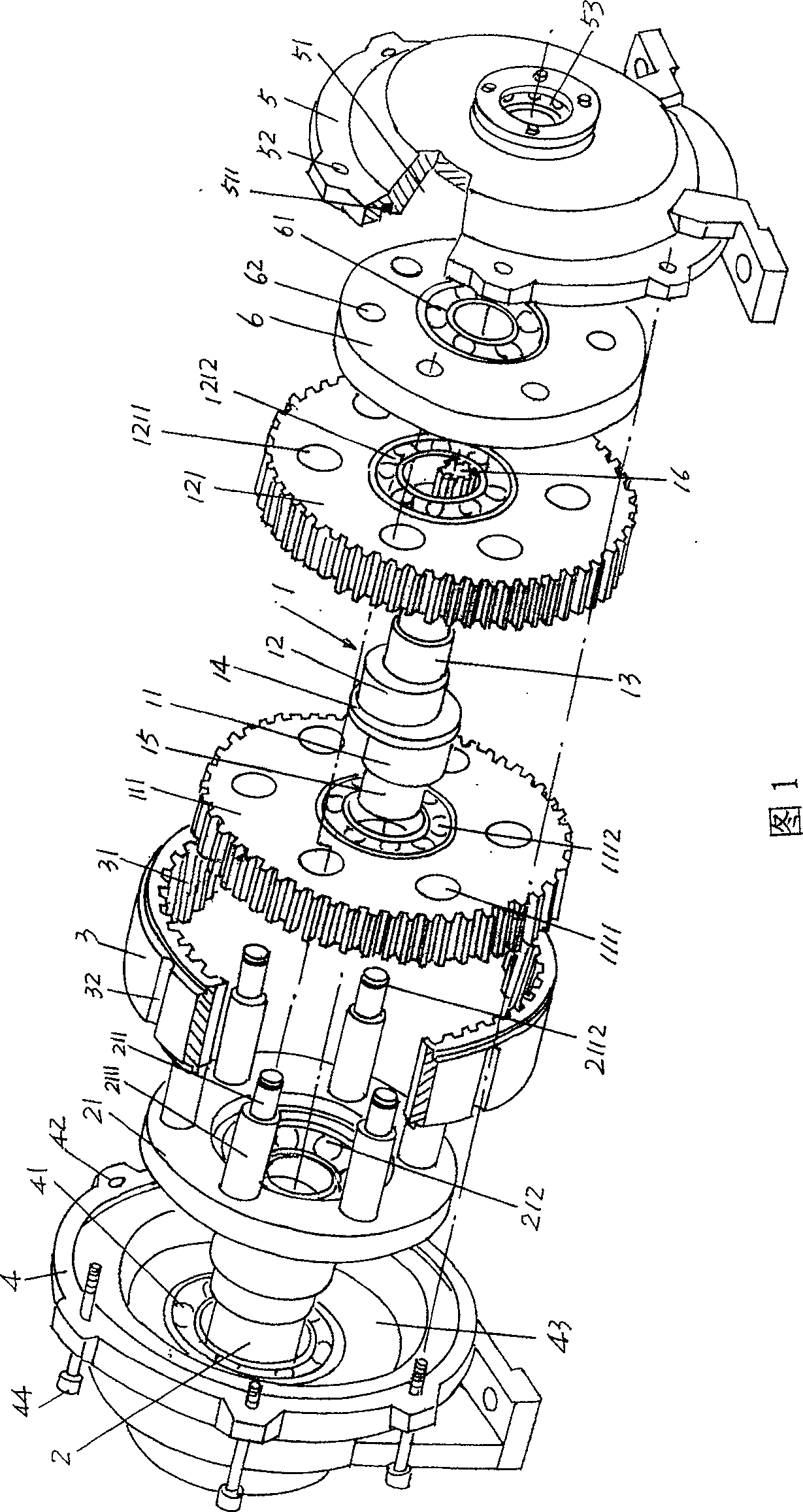

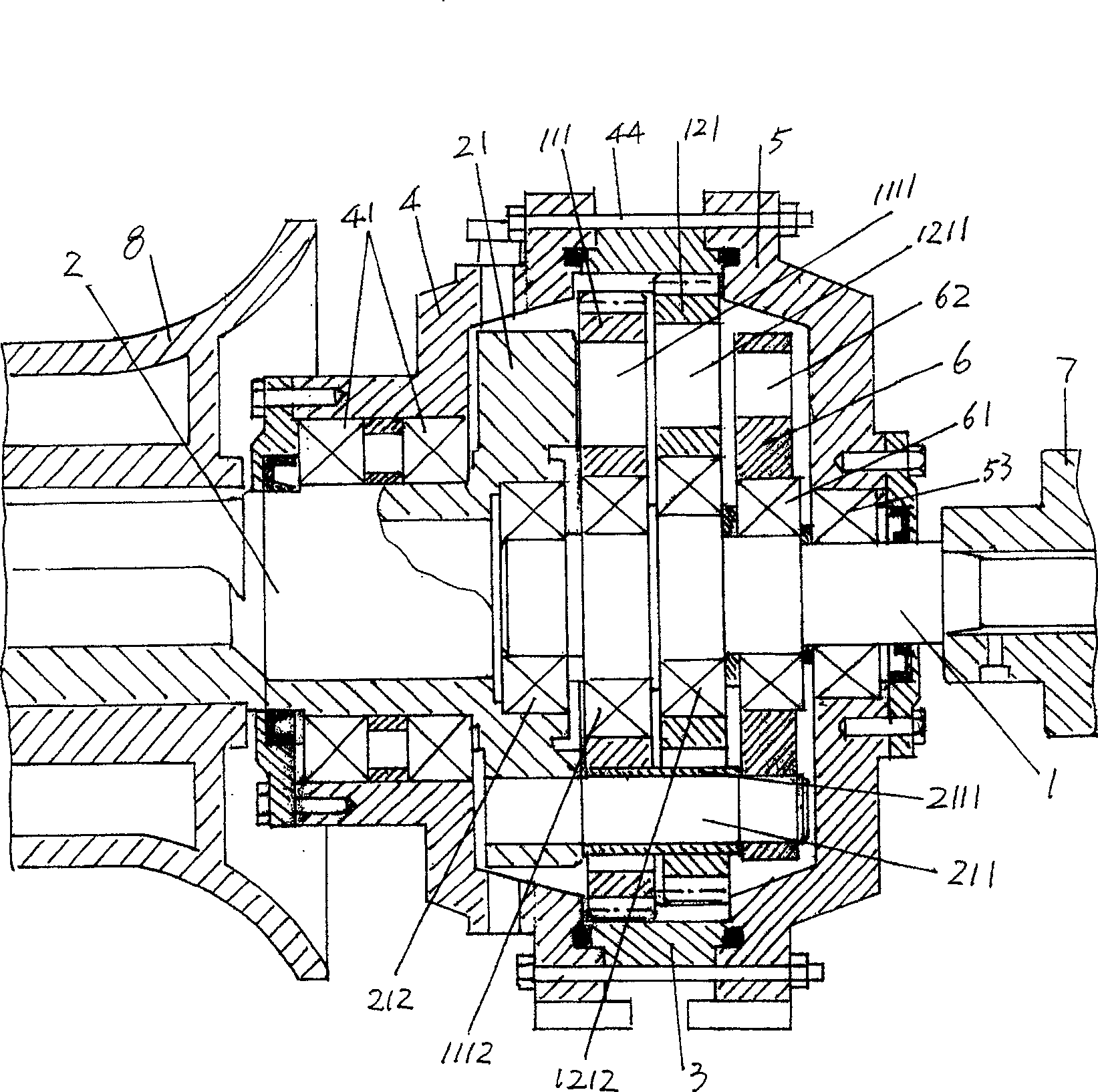

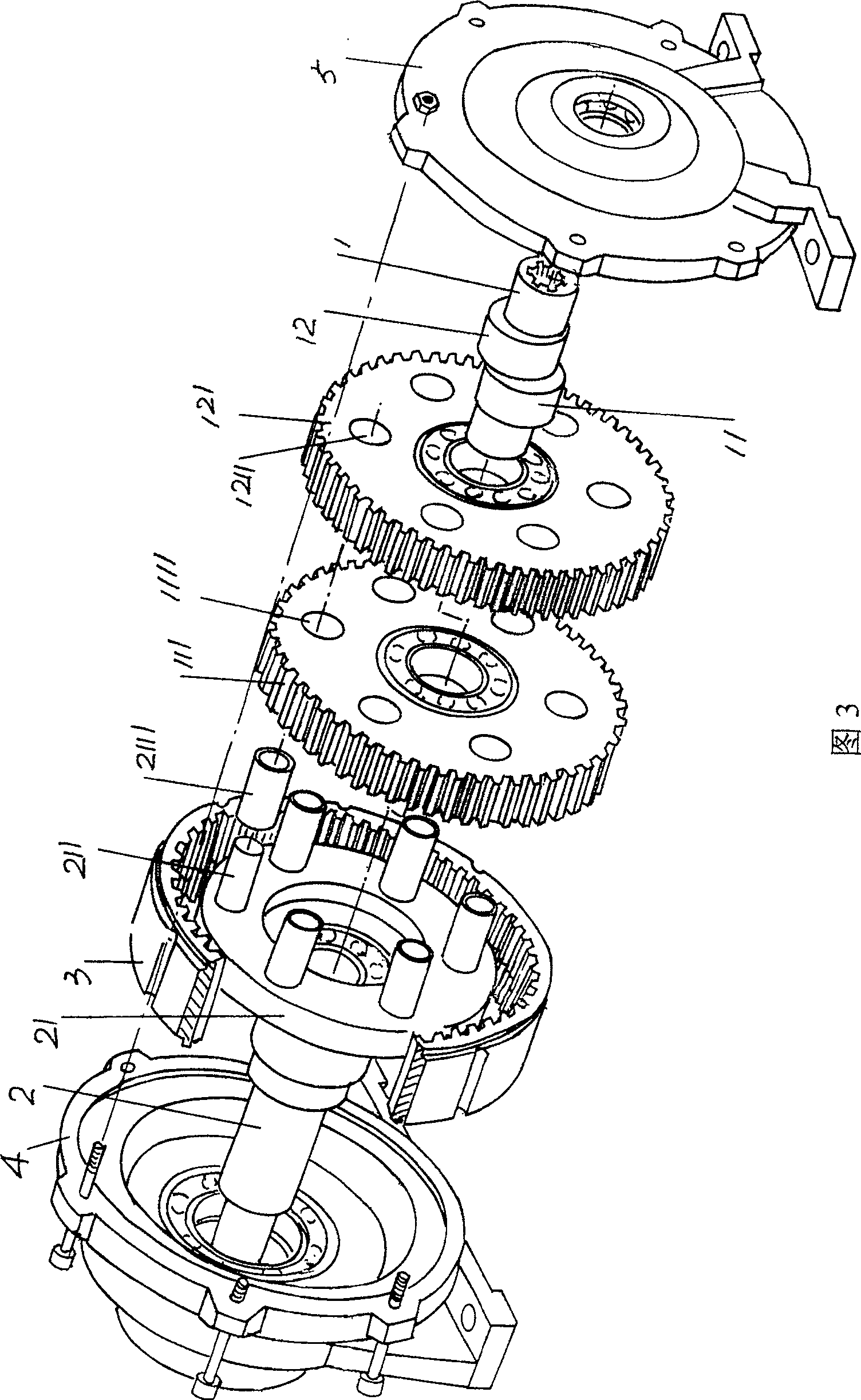

[0014] In Fig. 1, a camshaft 1, a pair of left and right cams 11, 12 are processed symmetrically in the middle of the camshaft 1, and left and right planetary gears 111, 121 are arranged on the left and right cams 11, 12 respectively. Specifically, the first and second bearings 1112 and 1212 are respectively installed in the center of the left and right planetary gears 111 and 121, and the left and right planetary gears 111 and 121 are set to On the left and right cams 11,12. A diaphragm 14 is expanded between the left and right cams 11, 12, which can keep a gap of the thickness of the diaphragm 14 between the gear faces of the left and right planetary gears 111, 121 to avoid mutual friction. The rims of the left and right planetary gears 111 and 121 are covered with teeth according to the required number. If the number of teeth is 51 teeth, the camshaft 1 rotates 360° for one turn, and the left and right planetary gears 111 and 121 only The transmission position of one tooth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com