Dental composite resin

A composite resin and resin technology, which is applied in dentistry, medical science, dental preparations, etc., can solve the problems of high price and achieve the effect of low price, good surface polishing performance and consistent light refraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

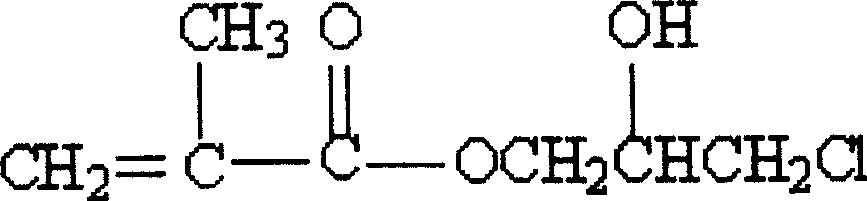

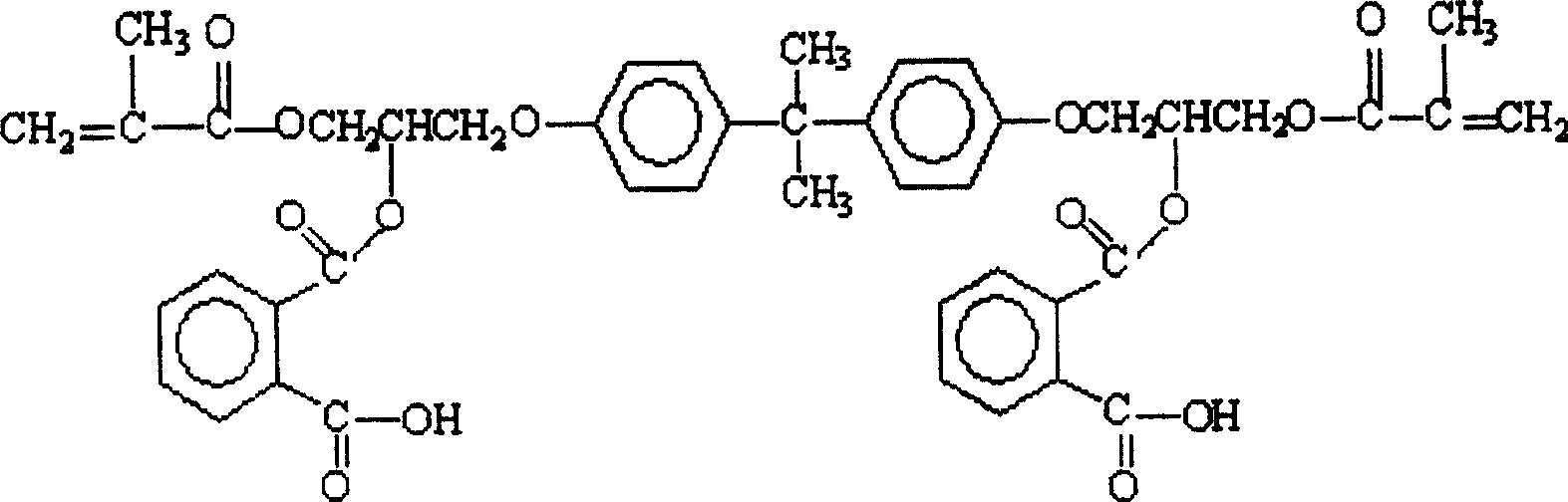

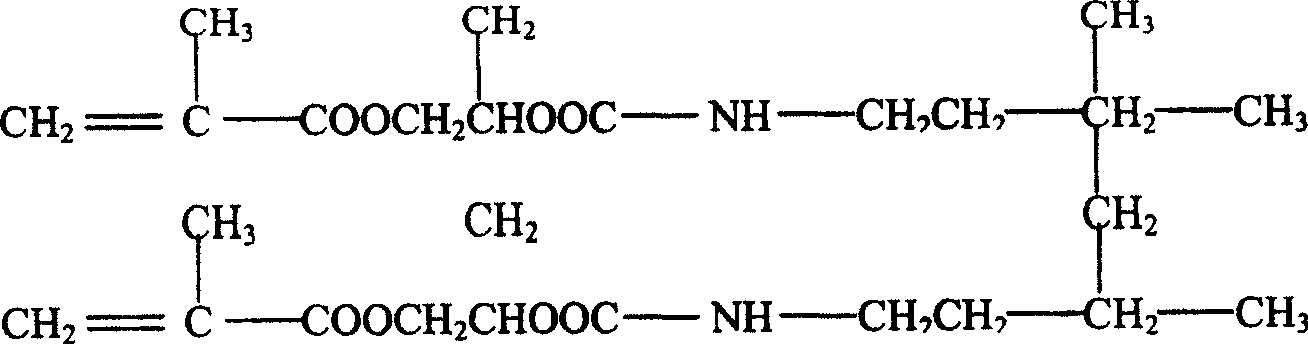

Method used

Image

Examples

Embodiment Construction

[0033] Adopt the chemical constituents of the composite resin of the present invention and the existing preparation method, the existing preparation method is: (1) the method for preparing nano silicon dioxide is the following specific steps: pass into 453ml, 24.72mol / L methanol solution, 653ml, 17.15mol / L absolute ethanol solution and 114g pure ammonia gas, stir for 0.5-1 hour; dissolve 3.4g PEG1000 and 2gPAA2000 in 645ml deionized water, add the aqueous solution of the dispersant to the reaction kettle In the middle, stir at high speed to make the solution mix evenly, slowly add 1000ml, 4.48mol / L Si(OC 2 h 5 ) 4 , Ultrasonic treatment is carried out at the same time as the reaction; the mixed solution is ultrasonically treated at 25°C in an ultrasonic wave with a frequency of 20100KHz for 5~60 minutes; after the reaction is completed, a uniform and stable sol is obtained; after the sol is frozen with liquid nitrogen, vacuum Dry in a low-temperature freeze dryer for 24-48 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com