Method for producing metallurgically binding metal composite seamless pipe

A metal clad tube and metal cladding technology, which is applied in the control equipment of metal extrusion, metal extrusion, manufacturing tools, etc., can solve the problems of high production cost, limited use environment, rising manufacturing cost, etc., and improve the grain structure. , the effect of improving overall performance and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

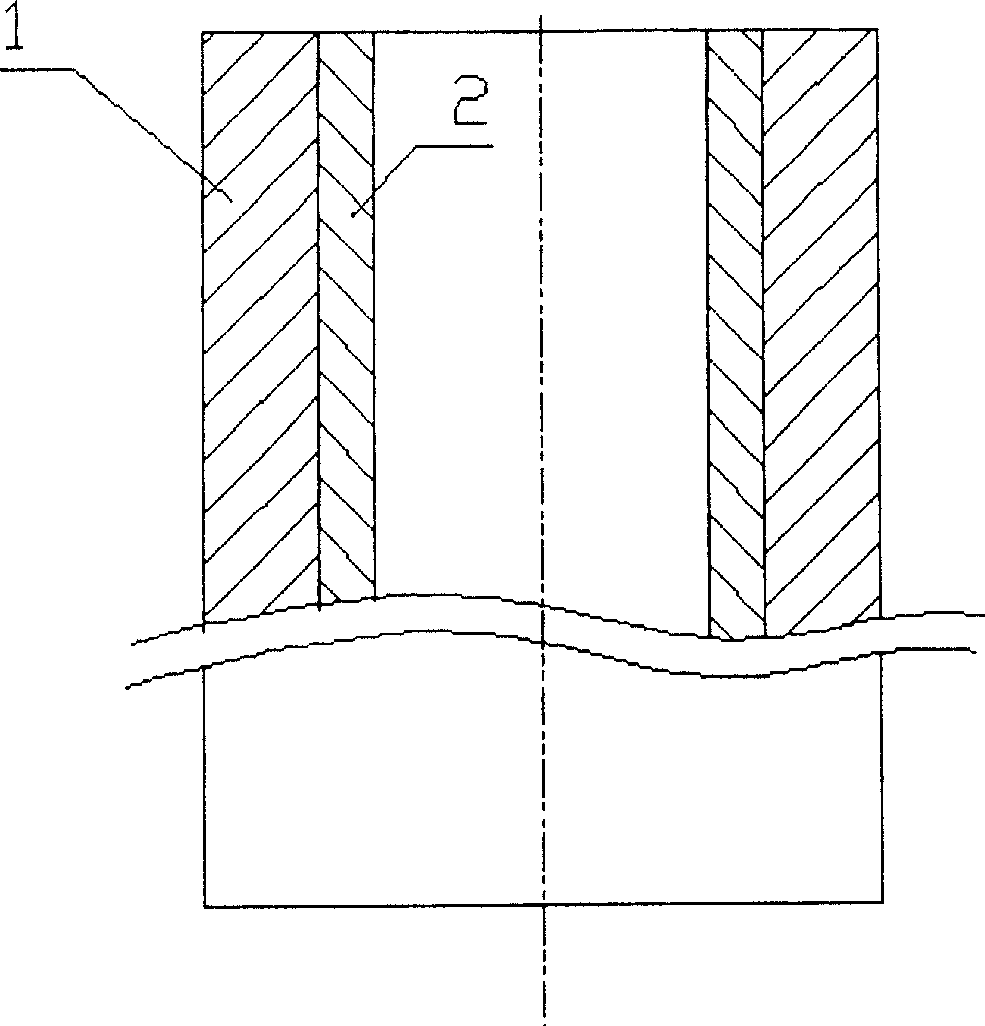

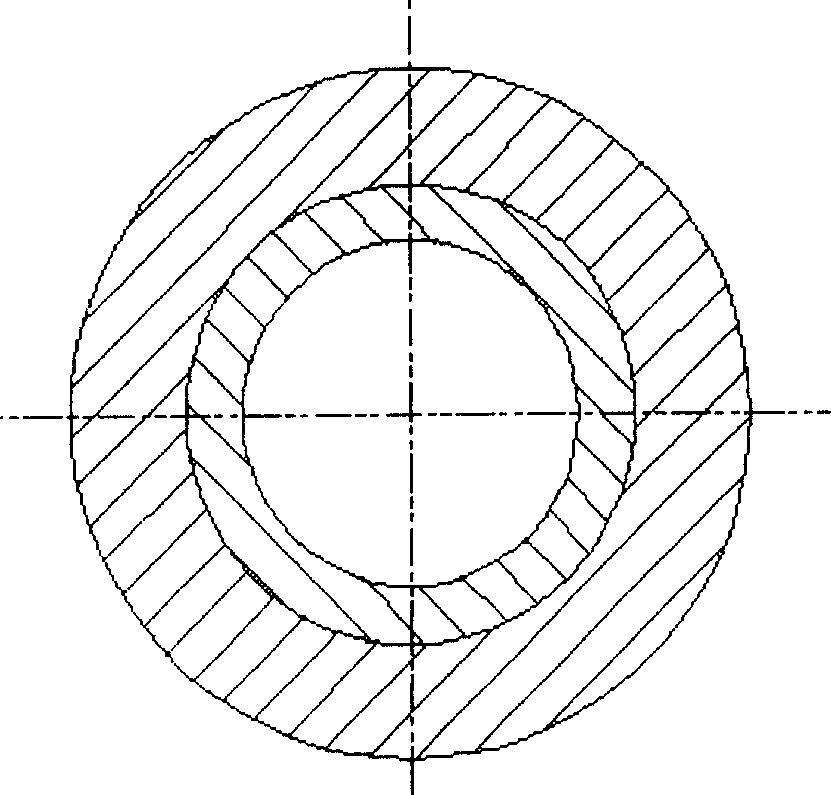

[0023] 1. According to the use and specifications of the metal composite seamless pipe, the double-layer structure centrifugal casting composite pipe blank is selected. The outer layer 1 is carbon steel 20Cr, the inner layer 2 is stainless steel 304, and the thickness of the inner stainless steel is 1 / 4 of the total wall thickness;

[0024] 2. The metal composite tube blank is preheated in a ring furnace first, and then heated in an induction heating furnace; the final heating temperature is 1050°C;

[0025] 3. Send the heated composite tube billet into the extruder for hot extrusion; the total compression deformation is 70%;

[0026] 4. Send the hot-extruded metal composite tube into the annealing furnace for high-temperature diffusion annealing. The diffusion annealing temperature is 830°C, and the annealing holding time is 2 hours;

[0027] 5. Straighten the heat-treated metal composite seamless pipe, remove burrs, cut heads, and cut to length;

[0028] 6. Inspection and...

example 2

[0030] 1. According to the use and specifications of the metal composite seamless pipe, the double-layer structure centrifugal casting composite pipe blank is selected. The outer layer 1 is stainless steel 304, the inner layer 2 is stainless steel 316, and the thickness of the inner stainless steel 316 is 1 / 2 of the total wall thickness;

[0031] 2. The metal composite tube blank is preheated in a ring furnace first, and then heated in an induction heating furnace; the final heating temperature is 1150°C;

[0032] 3. Send the heated composite tube billet into the extruder for hot extrusion. The total compression deformation is 95%;

[0033] 4. Send the hot-extruded metal composite tube into the annealing furnace for high-temperature diffusion annealing; the diffusion annealing temperature is 1050°C, and the annealing holding time is 4 hours;

[0034] 5. Straighten the heat-treated metal composite seamless pipe, remove burrs, cut heads, and cut to length;

[0035] 6. Inspect...

example 3

[0037] 1. According to the use and specifications of the metal composite seamless pipe, the double-layer structure centrifugal casting composite pipe blank is selected. The outer layer 1 is low alloy steel 35CrMo, the inner layer 2 is high temperature alloy steel 0Cr 13Mo, and the thickness of the inner layer high temperature alloy steel is 1 / 3 of the total wall thickness;

[0038] 2. The metal composite tube blank is preheated in the ring furnace first, and then heated in the induction heating furnace; the final heating temperature is 1250 °C;

[0039] 3. Send the heated composite tube billet into the extruder for hot extrusion; the total compression deformation is 80%;

[0040] 4. Send the hot-extruded metal composite tube into the annealing furnace for high-temperature diffusion annealing; the diffusion annealing temperature is 950°C, and the annealing holding time is 3 hours;

[0041] 5. Straighten the heat-treated metal composite seamless pipe, remove burrs, cut heads, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com