Method for modification of outer surface acidity of zeolite molecular sieve

A technology of zeolite molecular sieve and outer surface, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, hydrocarbons, etc., can solve the problems of repeated repetition and low loading efficiency, and achieve the effect of eliminating acidity and efficient acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

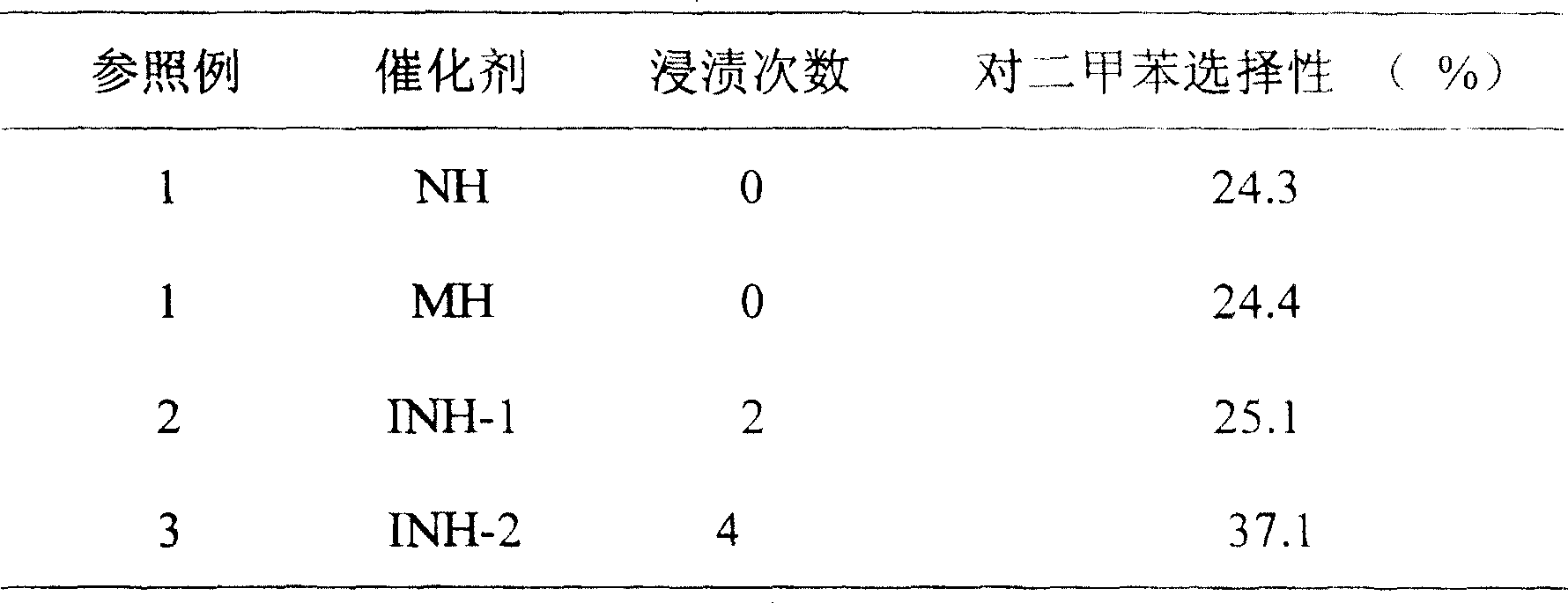

[0013] The catalyst prepared by liquid phase chemical impregnation method was used as reference. Take nano HZSM-5 at 40Kg / cm -2 Press down to form a tablet, break it into 10-20 mesh, weigh about 3.0 grams of 10-20 mesh HZSM-5, impregnate 2.6ml, 1.0mol / l cyclohexane solution of tetraethyl orthosilicate, and place it in an oven at 120°C Dry for 30 minutes, cool to room temperature, and then carry out the second impregnation, that is, add 2.6 ml, 1.0 mol / l cyclohexane solution of ethyl orthosilicate. Dry at 120°C for 30 minutes, calcine at 340°C for 1 hour, and 540°C for 5 hours. The catalyst prepared in this way is marked as INH-1.

[0014] Reference example 3

[0015] The catalyst prepared by liquid phase chemical impregnation method was used as reference. Take 3.0g of INH-1 catalyst and impregnate 2.6ml, 1.0mol / l cyclohexane solution of tetraethyl orthosilicate, dry in an oven at 120°C for 30 minutes, cool to room temperature and then impregnate for the second time, impregn...

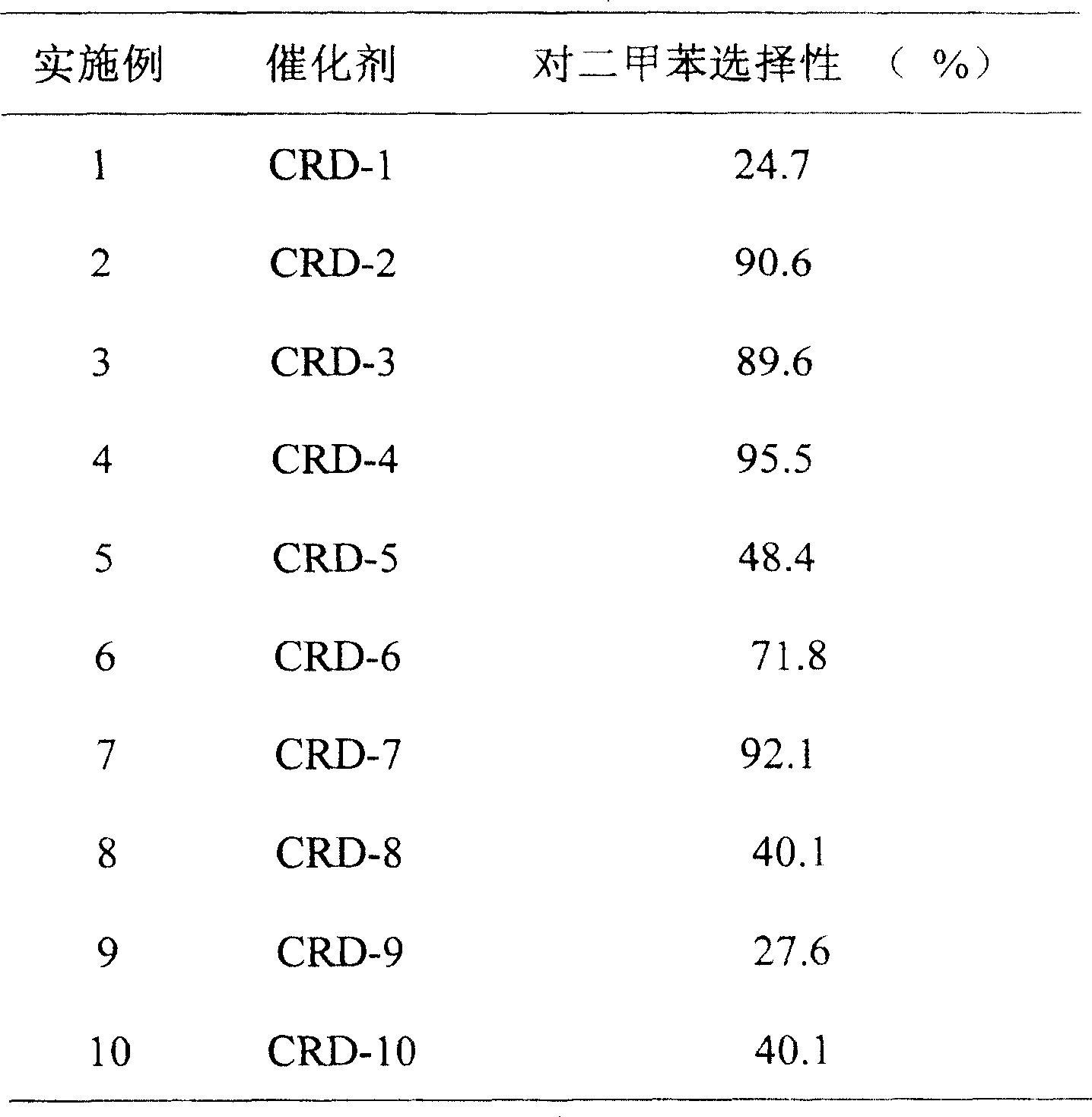

Embodiment 1

[0017] Will be at 40Kg / cm -2 The nanometer HZSM-5 formed by pressing down is crushed into 10-20 meshes, 3.0 grams is taken and placed in a crucible, and 2.6 ml, 2.0 mol / l cyclohexane solution of ethyl orthosilicate is added. Put the crucible into a polytetrafluoro-lined crystallization kettle (volume 100ml), keep the temperature at 170°C for 12 hours, and then cool to room temperature. Loosen the crystallization kettle and take out the crucible, bake at 340°C for 1 hour and 540°C for 5 hours, and the prepared catalyst is marked as CRD-1.

Embodiment 2

[0019] Using the catalyst CRD-1 prepared in Example 1 as the matrix, repeat the loading process once to prepare CRD-2. The specific operation steps are as follows: 3.0 grams of 10-20 mesh CRD-1 are placed in a crucible and 2.6ml of 1.0mol / l Cyclohexane solution of ethyl orthosilicate. Put the crucible into a crystallization kettle (100 ml) with a Teflon liner, keep the temperature at 170° C. for 12 hours, and then cool to room temperature. Loosen the crystallization kettle, take out the crucible, and bake at 340°C for 1 hour and 540°C for 5 hours. The catalyst prepared in this way is marked as CRD-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com