Wet coffee bean circulating fermentation system and process thereof

A technology of circular fermentation and wet beans, which is applied in the fields of green coffee processing, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc. It can solve the problems of unavailability of continuity, low degree of automation, and impact on work efficiency, etc. Problems, to save costs, improve work efficiency, improve the effect of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

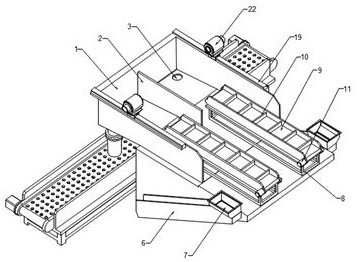

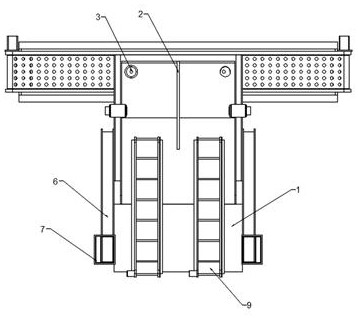

[0058] refer to Figure 1-Figure 16 As shown, a coffee wet bean circulation fermentation system includes a collecting and discharging tank, a uniform feeding device, a circulation cleaning device, a fermentation regulating tank and a waste water treatment tank, and the collecting and discharging tank is placed on the upper part of the hulling device , and the shelling device is connected to the fermentation regulating tank through a uniform feeding device, and the outlet of the fermentation regulating tank is provided with a circulation cleaning device, and one end of the circulation cleaning device is connected to the collection tank and the waste water treatment tank respectively, and is characterized in that : the collecting and discharging pool includes a box body 1, a material guide frame 8 and a material blanking mechanism, the inside of the box body 1 is divided into two chambers by the isolation plate 2, and the material guide frame 8 and the material blanking mechanism...

Embodiment 2

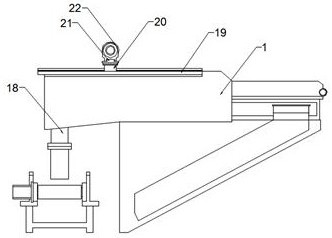

[0060] This embodiment is to further describe the unloading mechanism on the basis of the existing embodiment 1. The unloading mechanism includes the unloading port 3, the unloading pipe 18, the collecting tank, the slide table 20 and the shower head 22. , the feeding port 3 is placed inside the chamber, and the lower part of the feeding port 3 is connected to the collecting tank through the feeding pipe 18; the spray head 22 is connected with the sliding table 20 through the universal ball valve 21, and the lower part of the sliding table 20 It is slidingly connected with the sliding bar 19 on the box body 1; a material guide frame 8 is arranged inside the box body 1, and a first conveyor belt 9 is provided on the top of the material guide frame 8, and several conveyor belts 9 are provided on the top of the first conveyor belt 9 Baffle plate 10; one end of material guide frame 8 is provided with the first drive motor 11, and the first drive motor 11 is connected with the drive...

Embodiment 3

[0062] This embodiment further describes the first material guide table 40 on the basis of the existing embodiment 1. The first material guide table 40 and the second material guide table are connected to the fixed frame 8 through the first telescopic rod 39. Connected, the first material guide table 40 and the second material guide table are respectively provided with a first pulley 41 and a second pulley; the upper part of the loading frame 33 is provided with a conveyor belt 34, and the upper part of the conveyor belt 34 is provided with a number of feeding card slots 35; a scraper group is placed on the upper part of the guide table 36, and the scraper group includes a fixed clamp 51, a push shaft 52, a scraper table 45, a dry scraper 46, a first guide wheel 47 and a second guide wheel Wheel 49, both sides of fixed clamping plate 51 are respectively connected with the first guide groove 48 and the second guide groove 50 on the material guide table 36 through the first guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com