ZSM-5 molecular sieve catalyst, preparation method and application thereof

A technology of ZSM-5 and molecular sieve, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of long production process and high rejection rate of catalyst production, and achieve short process, high selectivity and efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

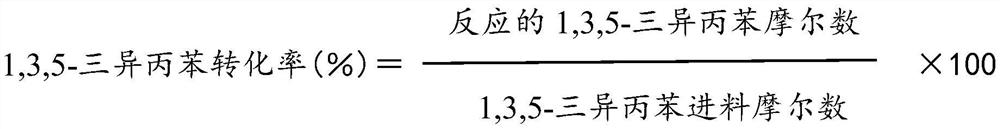

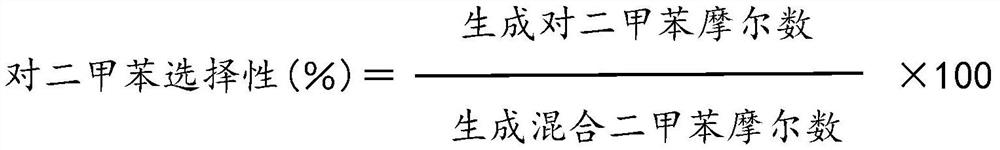

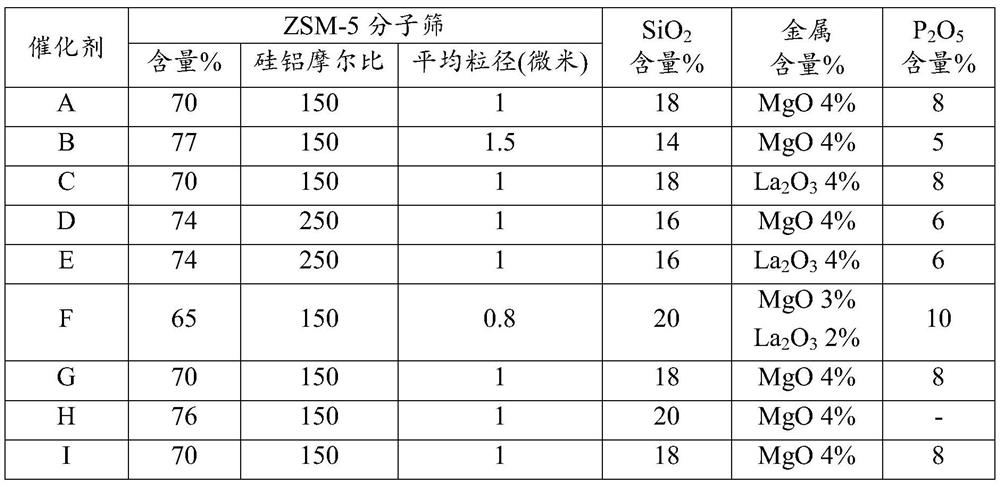

Embodiment 1

[0093] Dry base 70g ammonium type ZSM-5 molecular sieve (silicon aluminum molar ratio SiO 2 / Al 2 o 3 =150; ZSM-5 molecular sieve mean particle diameter is 1 micron) and 4g kale powder are mixed in the kneader, and in the kneader, adding the ammonium dihydrogen phosphate solution that is 40% by weight percentage concentration (with P 2 o 5 Accounting for molecular sieve dry basis weight 11.4%) and kneading for 30 minutes, then adding 45g of silica sol with a weight percentage concentration of 40% in the kneader to continue kneading into a dough shape, extruding into a cylindrical strip with a diameter of 1.7mm through a mold, The catalyst carrier was obtained by drying at 120°C and roasting at 550°C in an air atmosphere. The carrier was impregnated with an equal volume of magnesium nitrate solution (the MgO content accounted for 4.2% of the dry weight of the carrier), and then dried at 120°C and roasted at 500°C in an air atmosphere. ZSM-5 molecular sieve catalyst A with hi...

Embodiment 2

[0095] Dry base 77g ammonium type ZSM-5 molecular sieve (silicon aluminum molar ratio SiO 2 / Al 2 o 3 =150; ZSM-5 molecular sieve average particle diameter is 1.5 micron) and 5g scallop powder mixes in kneader, and adding weight percent concentration is 40% ammonium dihydrogen phosphate solution (in P 2 o 5 Accounting for 6.5% of molecular sieve dry basis weight) and kneading for 30 minutes, then adding 35g of silica sol with a concentration of 40% in the kneader to continue kneading into a dough shape, extruding into a cylindrical strip with a diameter of 1.7mm through a mold, The catalyst carrier was obtained by drying at 120°C and roasting at 550°C in an air atmosphere. The carrier was impregnated with an equal volume of magnesium nitrate solution (the MgO content accounted for 4.2% of the dry weight of the carrier), and then dried at 120°C and roasted at 500°C in an air atmosphere. ZSM-5 molecular sieve catalyst B with highly passivated outer surface. The composition o...

Embodiment 3

[0097] Dry base 70g ammonium type ZSM-5 molecular sieve (silicon aluminum molar ratio SiO 2 / Al 2 o 3 =150; ZSM-5 molecular sieve mean particle diameter is 1 micron) mixes in kneader with 5g kale powder, adds weight percent concentration in kneader and is the ammonium dihydrogen phosphate solution (with P 2 o 5 Accounting for molecular sieve dry basis weight 11.4%) and kneading for 30 minutes, then adding 45g of silica sol with a weight percentage concentration of 40% in the kneader to continue kneading into a dough shape, extruding into a cylindrical strip with a diameter of 1.7mm through a mold, The catalyst carrier was obtained by drying at 120°C and roasting in an air atmosphere at 550°C, and impregnating the carrier with an equal volume of magnesium nitrate solution (La 2 o 3 The content accounts for 4.2% of the weight of the dry basis of the carrier), and then the ZSM-5 molecular sieve catalyst C with a highly passivated outer surface is obtained by drying at 120° C....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com