Multi-row cluster-casting grinding ball mold plate

A casting mold, casting grinding technology, applied in casting molding equipment, casting mold, casting mold components, etc., can solve problems such as damage to the physical and mental health of operators, deterioration of the production environment, complex processes, etc., to improve the production environment and wide applicability. , The scientific and reasonable effect of the molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

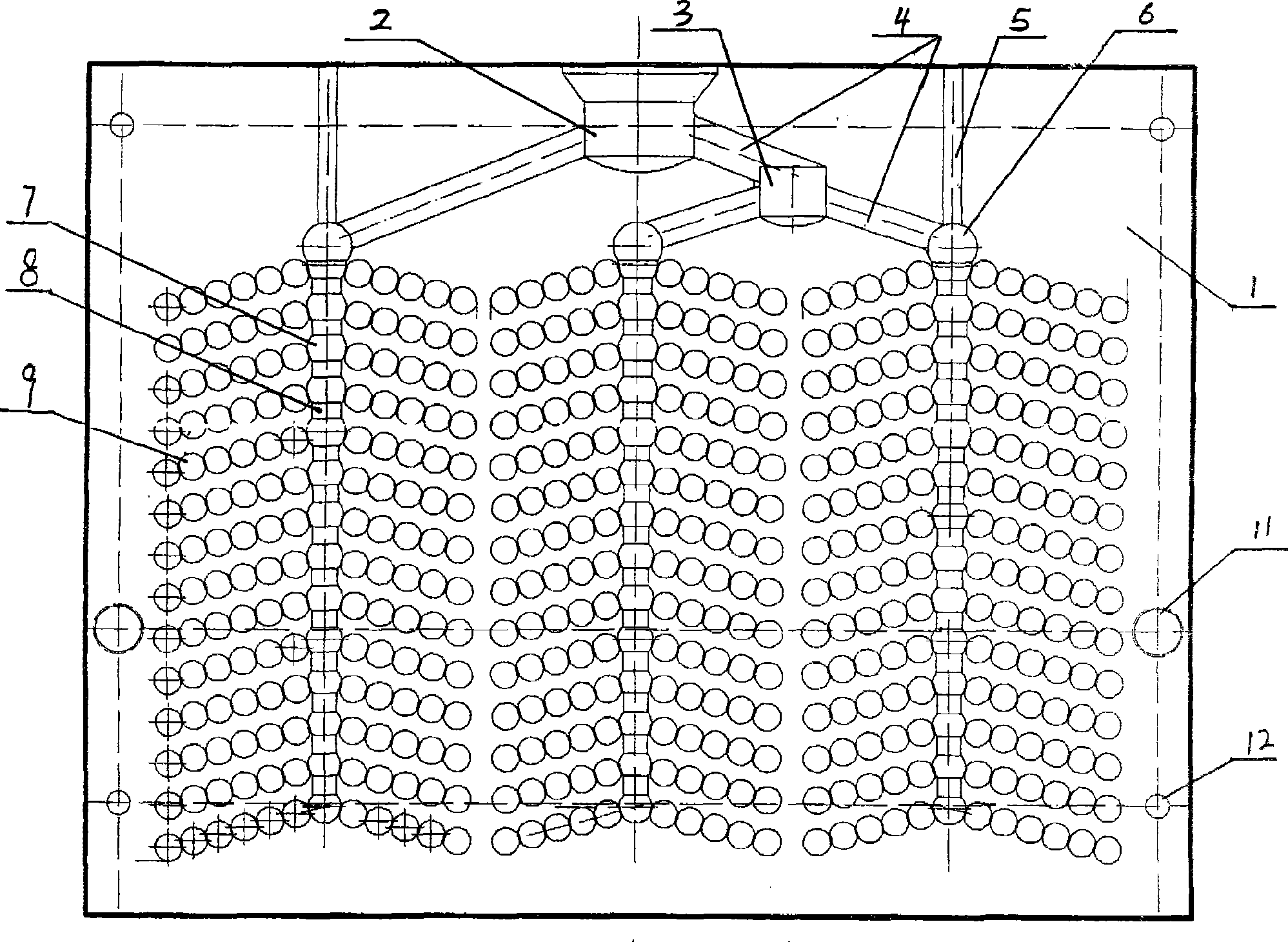

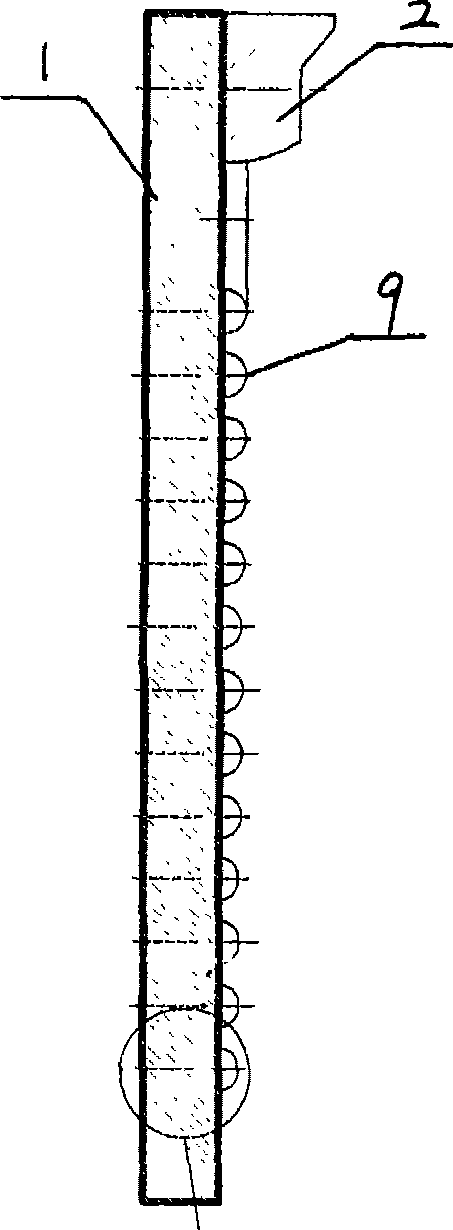

[0032] The multi-row series casting grinding ball casting pattern includes pattern plate 1, and the main gate riser module 2 is installed on one side of the pattern plate 1; the branch runner feeding module 3; the branch runner module 4; the exhaust channel module 5; Sprue feeding module 6; vertical sprue module and hemispherical mold body 9, see figure 1 .

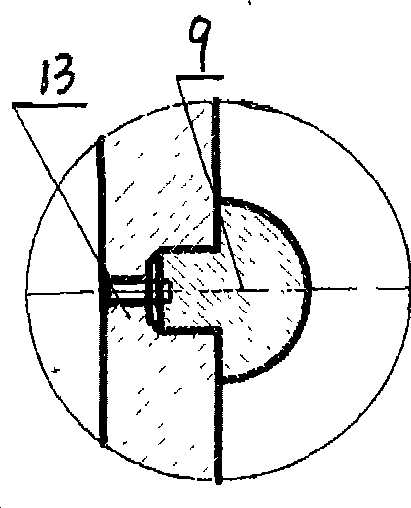

[0033] There are three parallel vertical sprue modules on the template 1, the vertical sprue modules are composed of hemispherical blocks 7 and semi-cylindrical blocks 8 staggered, and the hemispherical blocks 6 and semi-cylindrical blocks 7 on the vertical sprue modules are ten Four and thirteen. Six or five hemispherical phantoms 9 are respectively connected in series on both sides of the hemispherical table block 7, and semi-cylindrical thin plates 10 are sandwiched between the hemispherical phantoms 9 and coaxially connected in series to form a hemispherical phantom string, and the axis of the hemispherical phantom s...

Embodiment 2

[0040] see Figure 5 , on the template 1 and the branch runner module 4 connected with the main gate riser module, there is a branch feeding module 3, and the two sides of the branch feeding module 3 are respectively connected with the branch runner module 4, and the two sides of the branch feeding module The sprue modules 4 are respectively connected with the vertical sprue feeding modules 6 .

[0041] Depend on Figure 5 It can be seen that by setting up the branch channel feeding module 3, three parallel vertical sprue modules can be arranged on one template, and the hemispherical block 6 and the semicylindrical block 7 on the vertical sprue module are respectively thirteen and twelve. Five or four hemispherical mold bodies 9 are connected in series on both sides of the hemispherical table block 6, and 13 strings of hemispherical mold bodies are respectively connected to both sides of each vertical runner module. The diameter of the hemispherical mold bodies 9 on each stri...

Embodiment 3

[0044] see Image 6 , on the basis of Embodiment 2, the two sides of the main gate riser module 2 are connected with two branch runner modules 4, and each branch runner module 4 is respectively connected with a vertical runner module. That is to say, two parallel vertical sprue modules are arranged on a mold plate, and the two sides of the vertical sprue module are respectively connected with semi-cylindrical blocks 7, and the two sides of the semi-cylindrical blocks 7 are respectively connected in series with four or three hemispherical mold bodies 9, each Eight strings of hemispherical mold bodies are respectively connected to both sides of the vertical sprue module, and the diameter of the hemispherical mold body 9 on each string of hemispherical mold bodies is Φ50.

[0045] Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com