Method and apparatus for detecting surface quality of egg

A quality inspection and egg technology, applied in the field of egg surface quality inspection and devices, can solve the problems of insufficient accuracy, limited inspection, single inspection, etc., achieve high repeatability and adaptability, eliminate the interference of subjective factors, and accurately determine and graded effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

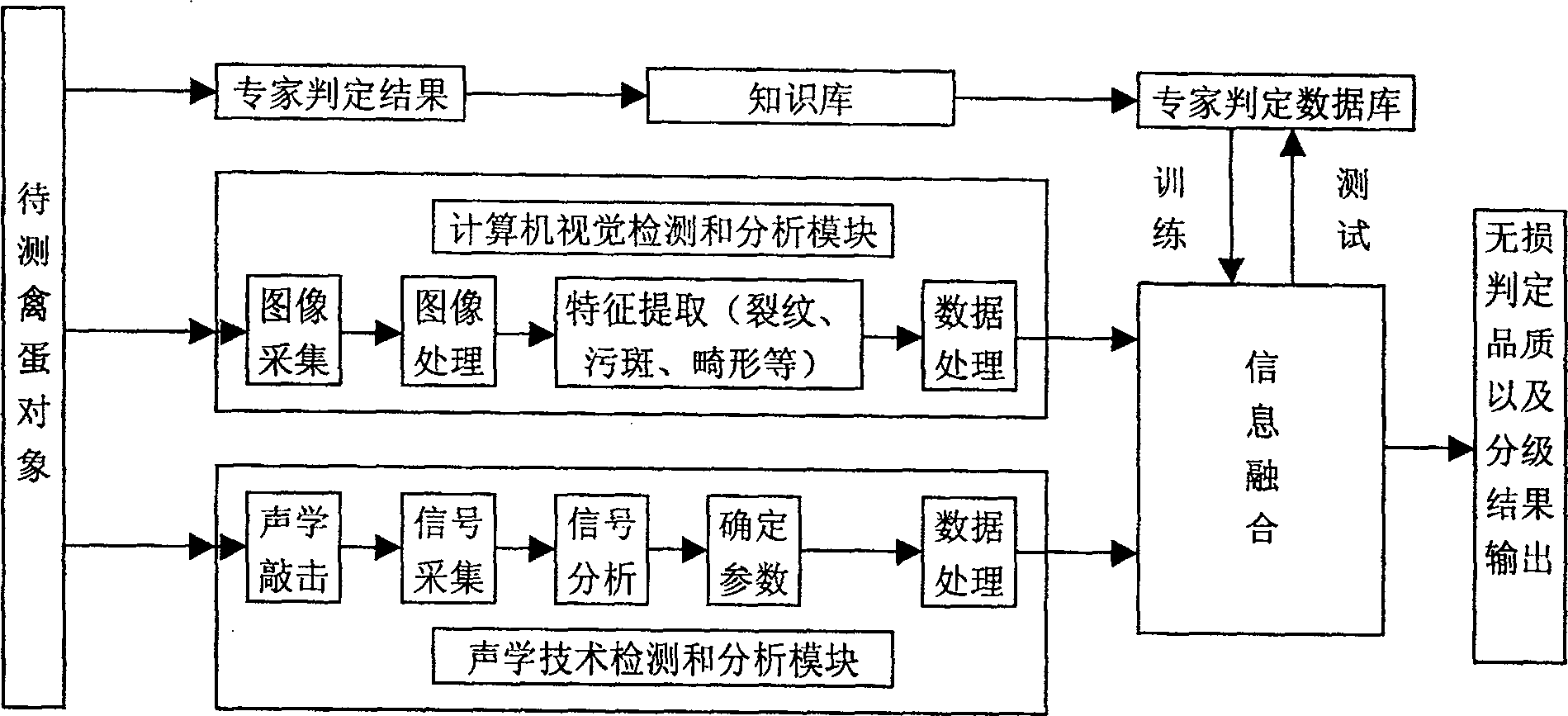

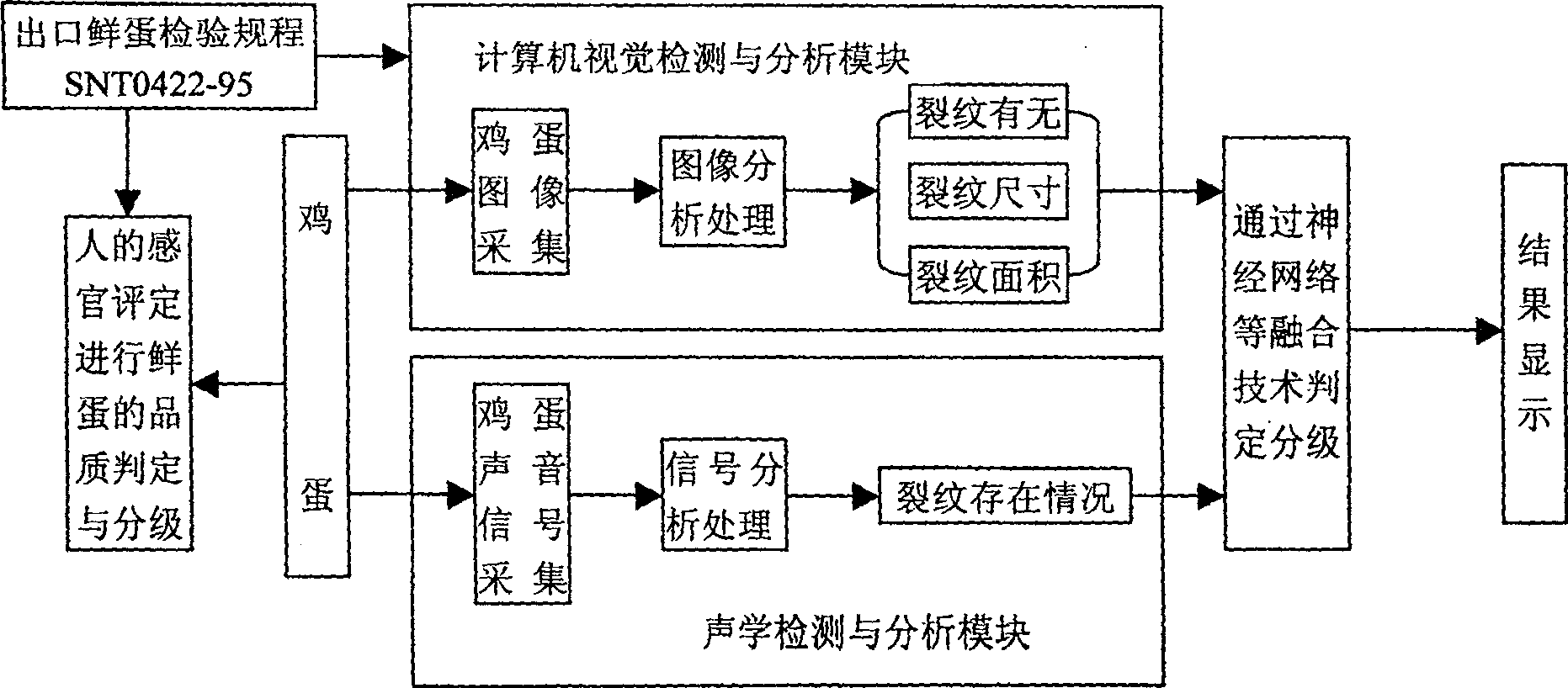

[0046] refer to image 3 , is a schematic diagram of the system scheme for egg shell crack detection. According to the relevant requirements of the national standard for fresh egg export inspection, the quality assessment and classification are carried out according to conventional detection methods, and then these eggs are used as samples. The advanced non-destructive testing device is used for testing, and an expert judgment database related to the knowledge base is established.

[0047] The computer vision detection and processing in the figure includes egg image acquisition, image preprocessing, image analysis and feature extraction, which can determine the existence of cracks and the size of the cracks. The image acquisition uses a CCD camera to take pictures of egg samples in a sealed chamber , transmitted to the computer through the image acquisition card, wherein there is a light source inside the seal, and the image acquisition can be fixed inside the computer. The c...

Embodiment 2

[0054] 1 Test material

[0055] The test materials are pollution-free eggs provided by Jiangsu Yuanchuang Poultry Industry Development Co., Ltd., and the chicken breed is Roman laying hens. The fresh eggs 1-2 days after delivery were divided into two batches. All the eggs used in the experiment were carefully checked by manual experts and judged as cracked eggs or intact eggs. The first eggs were used to build the knowledge base and expert judgment database. There are 290 eggs in total, including 150 intact eggs and 140 eggs with cracked shells. Some of the eggs with cracked shells are cracks artificially made from intact eggs. The size and distribution of cracks are relatively random. The second batch of eggs was used by inspection experts to judge the accuracy of the database. There were 237 eggs in total. According to the results of manual careful inspection, 126 eggs were intact and 111 eggs had cracked shells. The accuracy rate of the system grading results is obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com