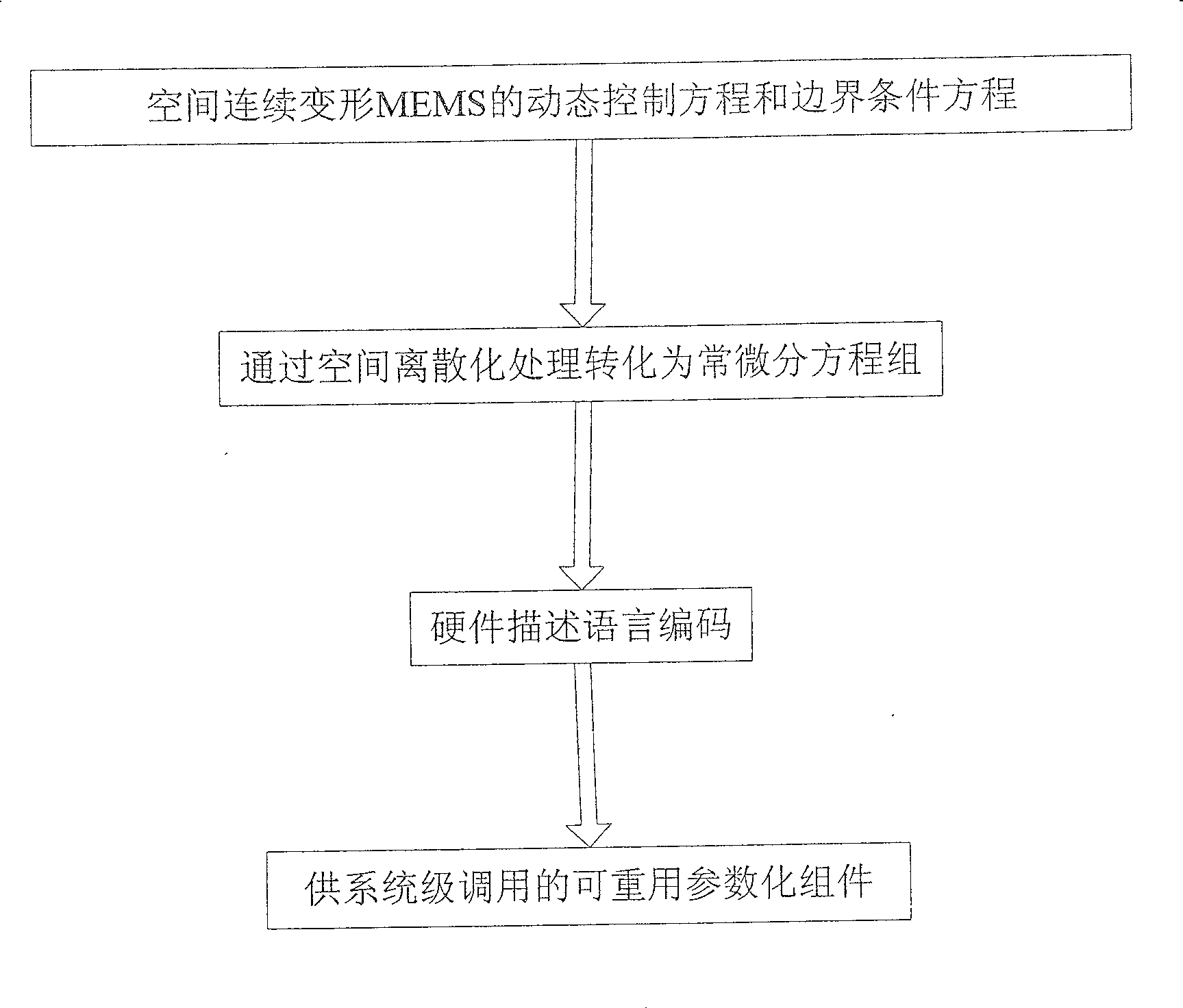

Reusable parameter module model building method for space continuous deformation MEMS

A modeling method, parametric technology, applied in chemical instruments and methods, electrical components, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

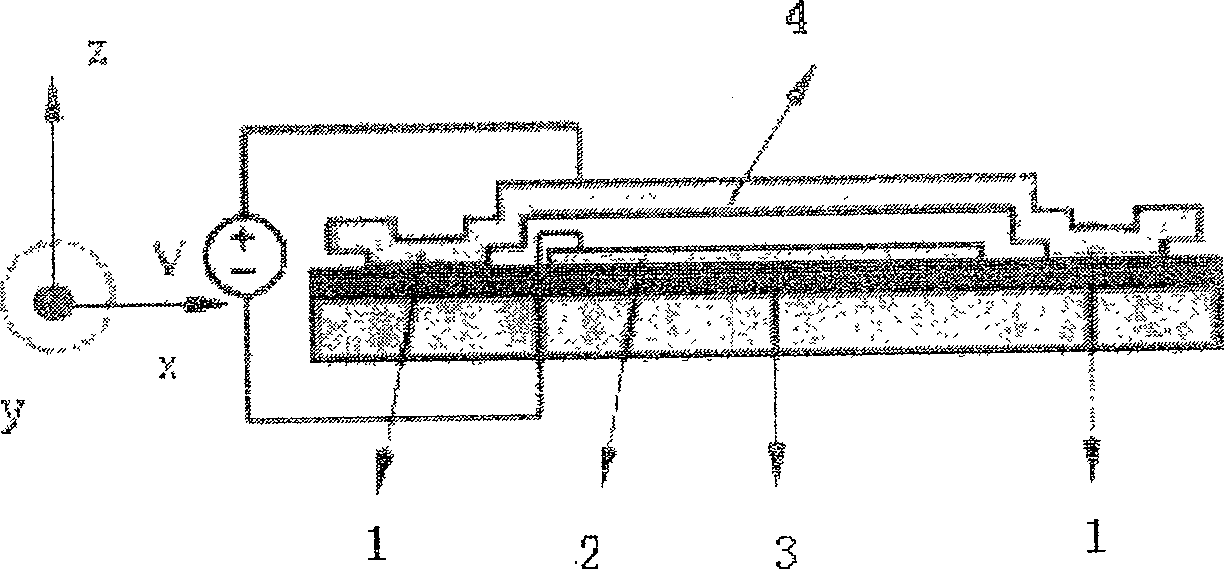

[0021] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS Implementation Example 1: A method for establishing a component model of an electrostatically actuated microbeam.

[0022] Step 1: Determine the dynamic control equations and boundary condition equations describing each energy domain and its coupling state according to the energy domains and coupling modes involved in the electrostatically actuated microbeam.

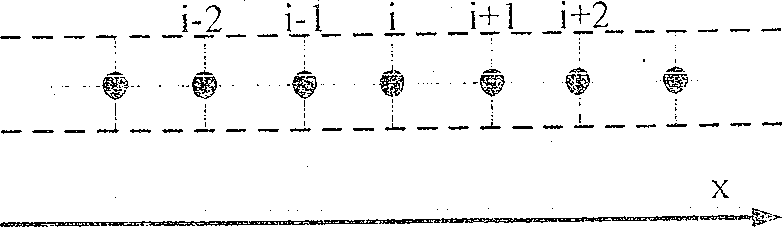

[0023] attached figure 2 It is a schematic diagram of a double-terminal fixed electrostatically actuated microbeam structure, which is a common structure in MEMS systems and is widely used in RF switches, micro accelerometers, pressure sensors and other devices. When a voltage V is applied between the upper and lower electrodes, the upper electrode is deformed under the action of electrostatic attraction, and the magnitude of the electrostatic force received by each point on the beam is related to the deflection of this point. The axis of the beam when it is not...

Embodiment 2

[0042] Implementation example 2: a method for establishing a component model of a capacitive pressure sensor.

[0043] Step 1: Determine the dynamic control equations and boundary condition equations describing each energy domain and its coupling state according to the energy domains involved in the capacitive pressure sensor and their coupling methods.

[0044] attached Figure 5 It is a schematic diagram of the structure of a capacitive pressure sensor, and its elastic element is composed of a diaphragm fixed around it. The deformation equation of the diaphragm after being subjected to external pressure and electrostatic pressure can be described as:

[0045] D ∂ 4 w ∂ x 4 + 2 D ∂ 4 w ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com