Sealing device for luminous tube

A technology of sealing device and lamp tube, which is applied in the direction of electric tube/lamp closing, discharge tube/lamp manufacturing, electrical components, etc., can solve problems such as energy waste, product scrapping, glass thickness, etc., and achieve energy saving, short time, evenly stacked effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

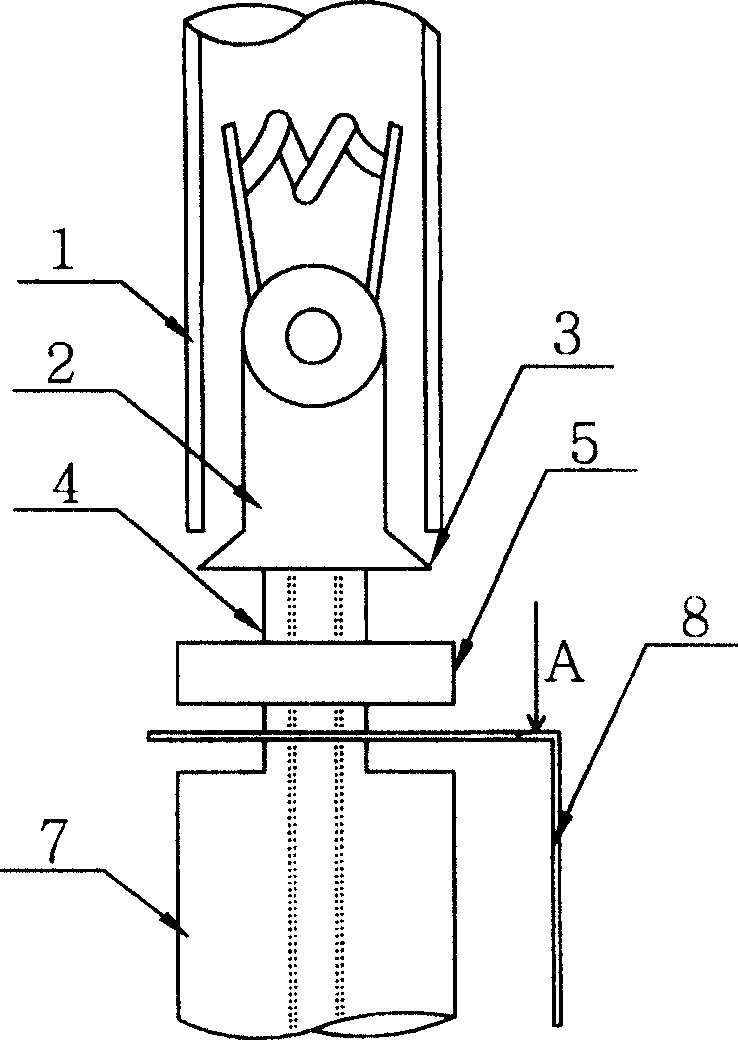

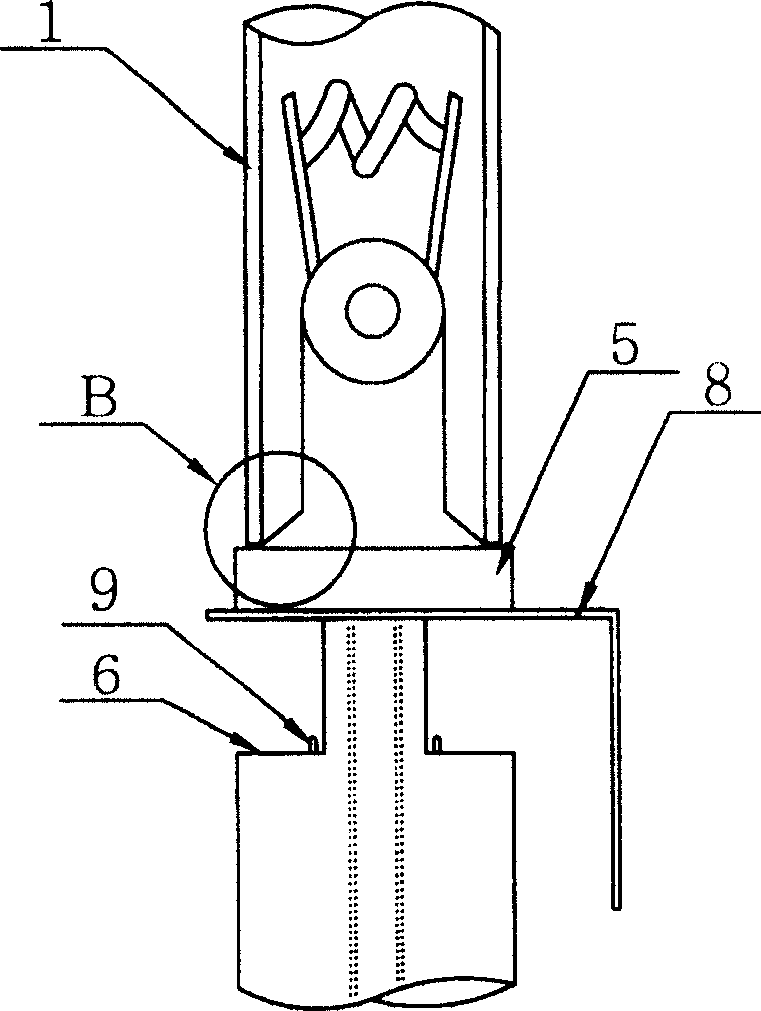

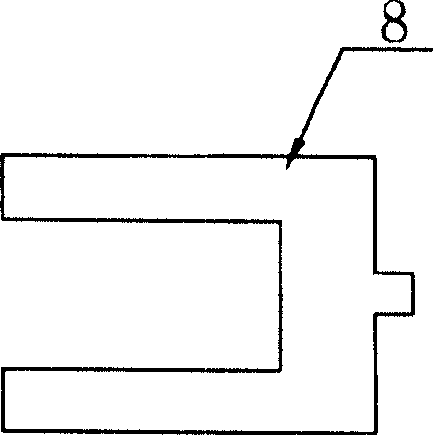

[0027] see figure 1 , 2 , the lamp tube sealing device of the present invention comprises a stem support rod 7, the upper part of the stem support rod 7 is a ejector rod 4 with a smaller diameter, and the ejector rod 4 directly lifts up the middle part of the stem 2, outside the stem support rod 7 A ring-shaped compression support roller 5 is sleeved, and the compression support roller 5 can move up and down along the core column support rod 7 through the support of the toggle device 8 . Toggle device 8 can be shift fork (see image 3 ) or ejector pin and other forms

[0028] The diameter of the bottom of the stem support rod 7 is greater than the diameter of the top mandrel 4, so an outer ring surface 6 is formed, and the outer ring surface 6 can prevent the compression support roller 5 from falling. The outer ring surface 6 is provided with several protrusions 9, so that when the pressing support roller 5 falls, there is still a certain gap with the outer ring surface 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com