Outdoor condensing unit for split air conditioners

A technology of condensing units and air conditioners, applied in air conditioning systems, heating methods, space heating and ventilation, etc., can solve the problems of easy oxidation, attenuation, and low heat dissipation of hydrophilic aluminum sheets, and overcome the problems of easy corrosion, installation Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

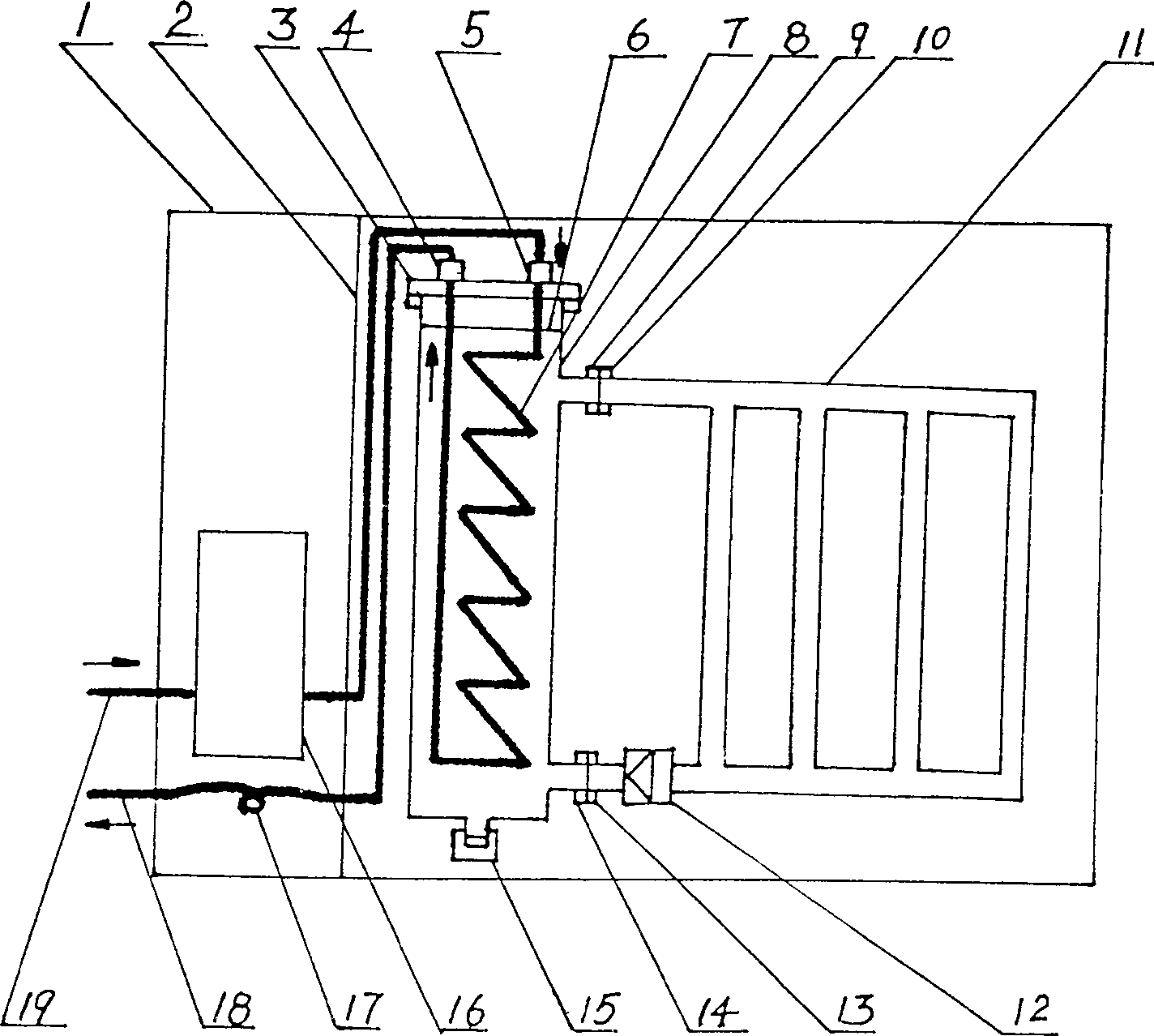

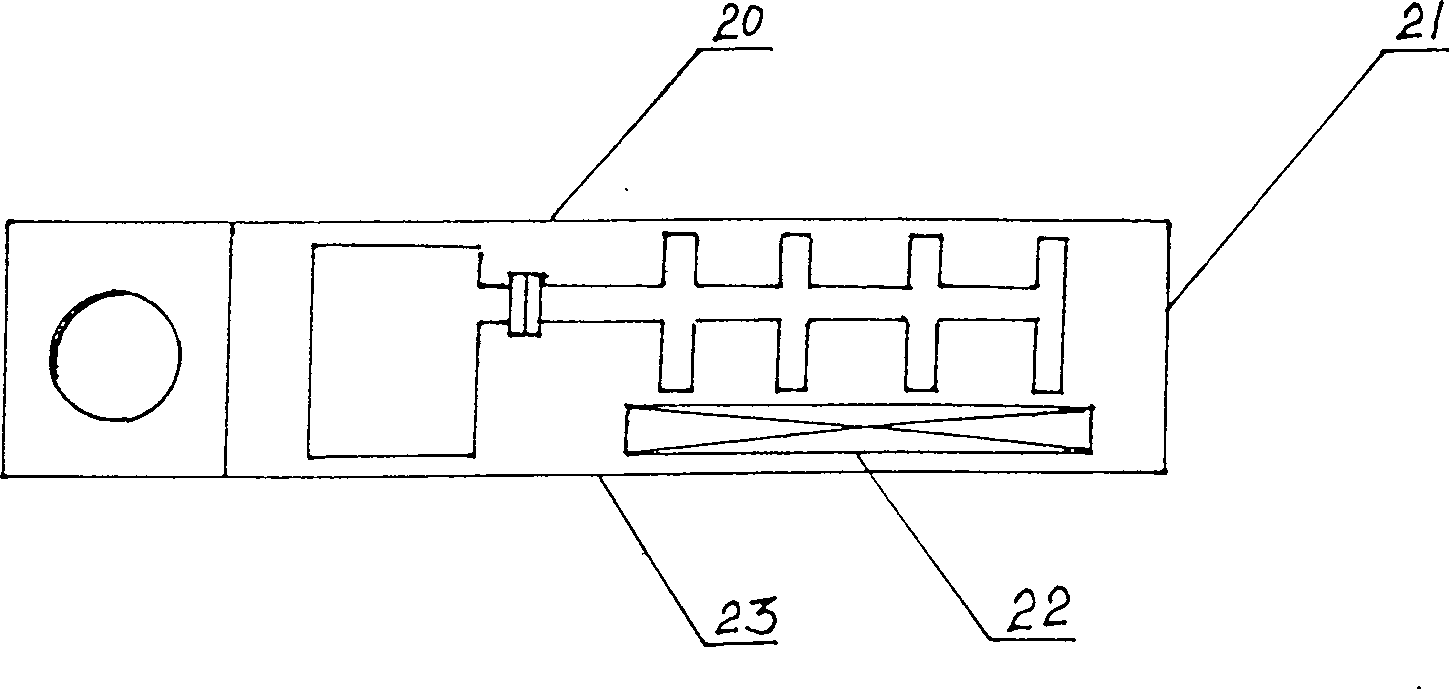

[0021] In the figure, 1 is the casing of the outdoor condensing unit, 2 is the isolation plate, 3 is the oil tank cover, 4 is the refrigerant outlet joint, 5 is the refrigerant inlet joint, 6 is the cooling oil, 7 is the refrigerant condenser, and 8 is the oil tank. 9 is the oil outlet flange of the oil tank, 10 is the oil inlet flange of the cooling oil radiator, 11 is the cooling oil radiator, 12 is the oil pump, 13 is the oil outlet flange of the cooling oil radiator, and 14 is the oil inlet of the oil tank. Lan, 15 is an oil discharge valve, 16 is a compressor, 17 is a capillary tube, 18 is a refrigerant outlet, 19 is a refrigerant inlet, 20 is a rear side plate of a casing, 21 is a right side plate of a casing, and 22 is a cooling fan. 23 is the front side plate of the casing.

[0022] When the present invention is implemented, it must be placed outdoors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com