Piezoelectric ceramic driving power based on voltage and current composite control

A piezoelectric ceramic drive and compound control technology, which is applied in the direction of generator/motor, piezoelectric/electrostrictive/magnetostrictive device, piezoelectric effect/electrostrictive or magnetostrictive motor, etc., can solve the problem of improving Issues such as cost, oscillation, and impact on dynamic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in more detail below in conjunction with accompanying drawing example:

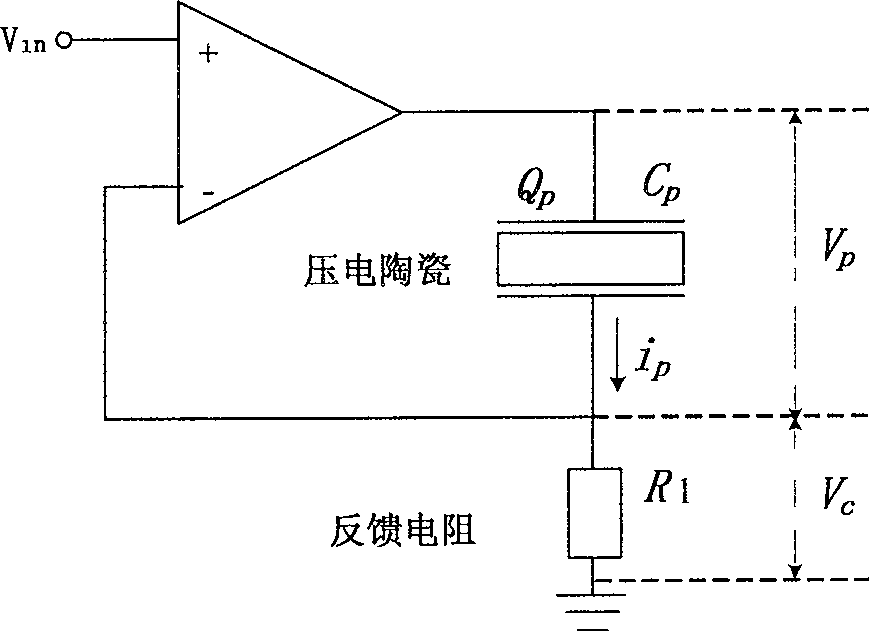

[0027] combine figure 1 , the inner ring is based on the principle of the current-controlled piezoelectric ceramic drive power supply, including piezoelectric ceramic Z and a high-voltage operational amplifier A1 connected to both ends of the piezoelectric ceramic, and a feedback resistor R1 is connected in series with the piezoelectric ceramic.

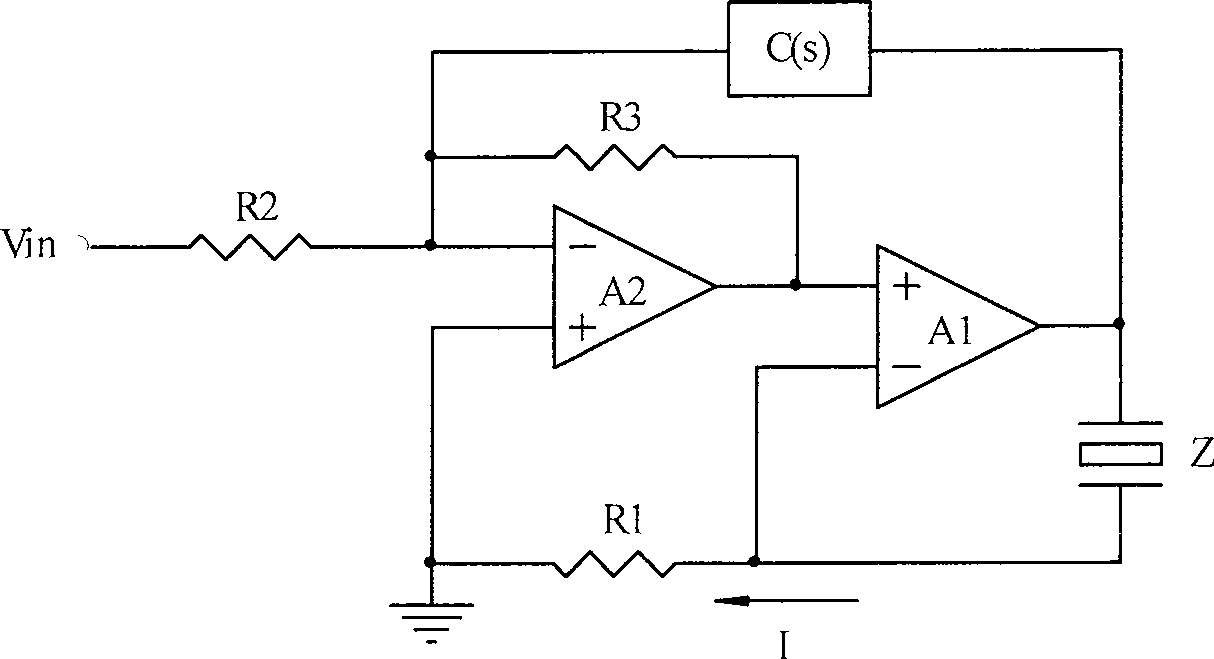

[0028] combine figure 2 , the embodiment of the present invention is to increase the voltage outer loop with proportional-integral controller outside the current-type inner loop, and the proportional-integral controller is made up of operational amplifier A2, resistor R2, variable resistor R4 and variable capacitor C1, and the whole The outer ring is provided with a switch S1.

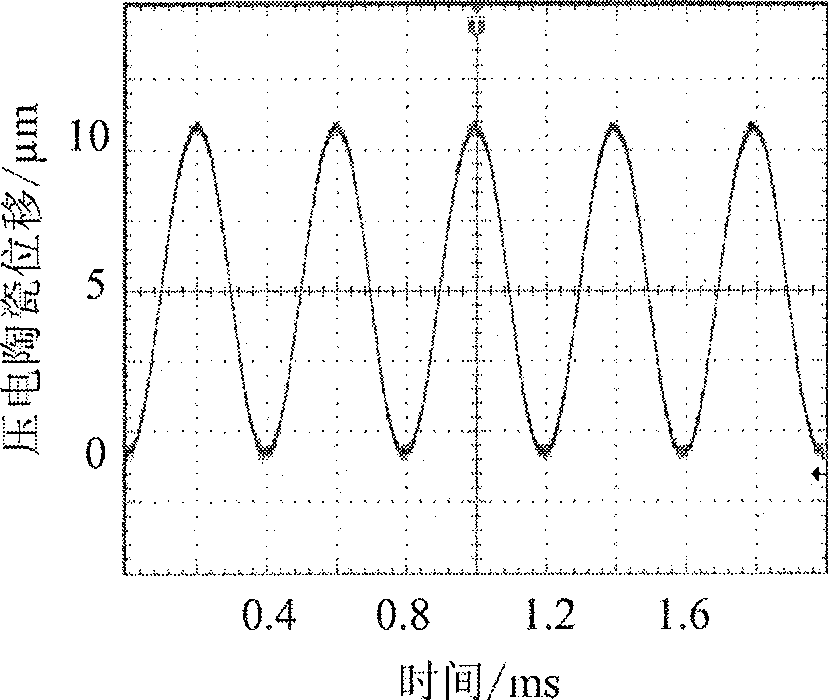

[0029] combine Figure 7 , the piezoelectric ceramic drive power supply based on composite control is composed of three circuit modules conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com