Semiconductor device with tunable energy band gap

A technology of semiconductors and energy bands, applied in the direction of semiconductor devices, electrical solid devices, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

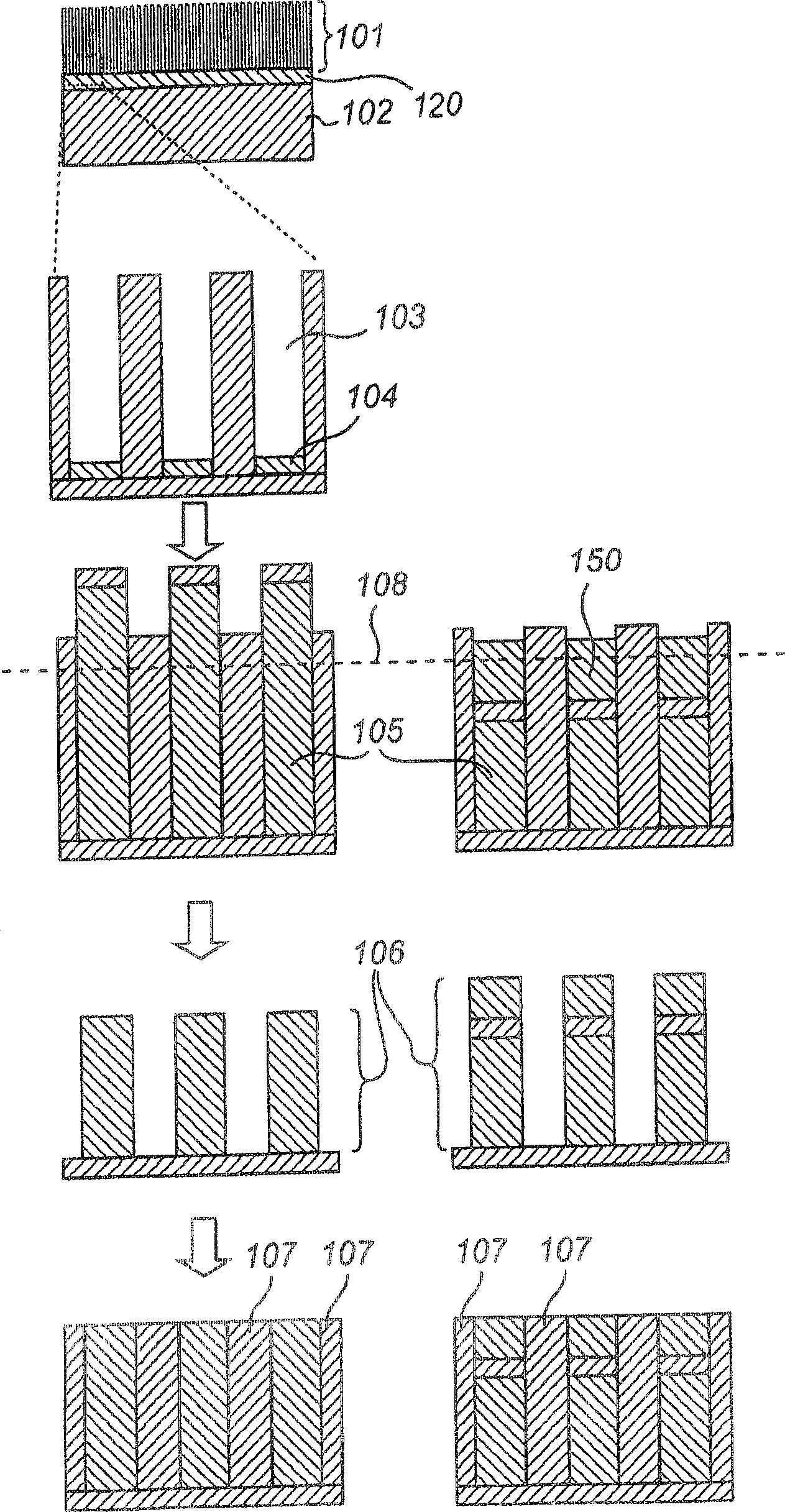

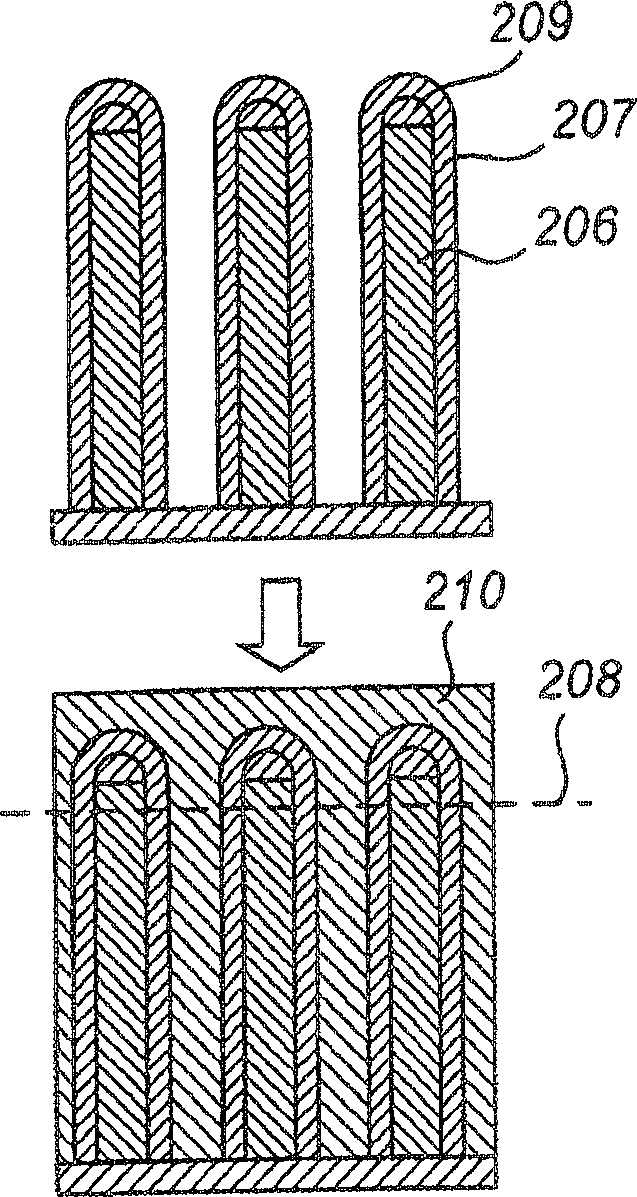

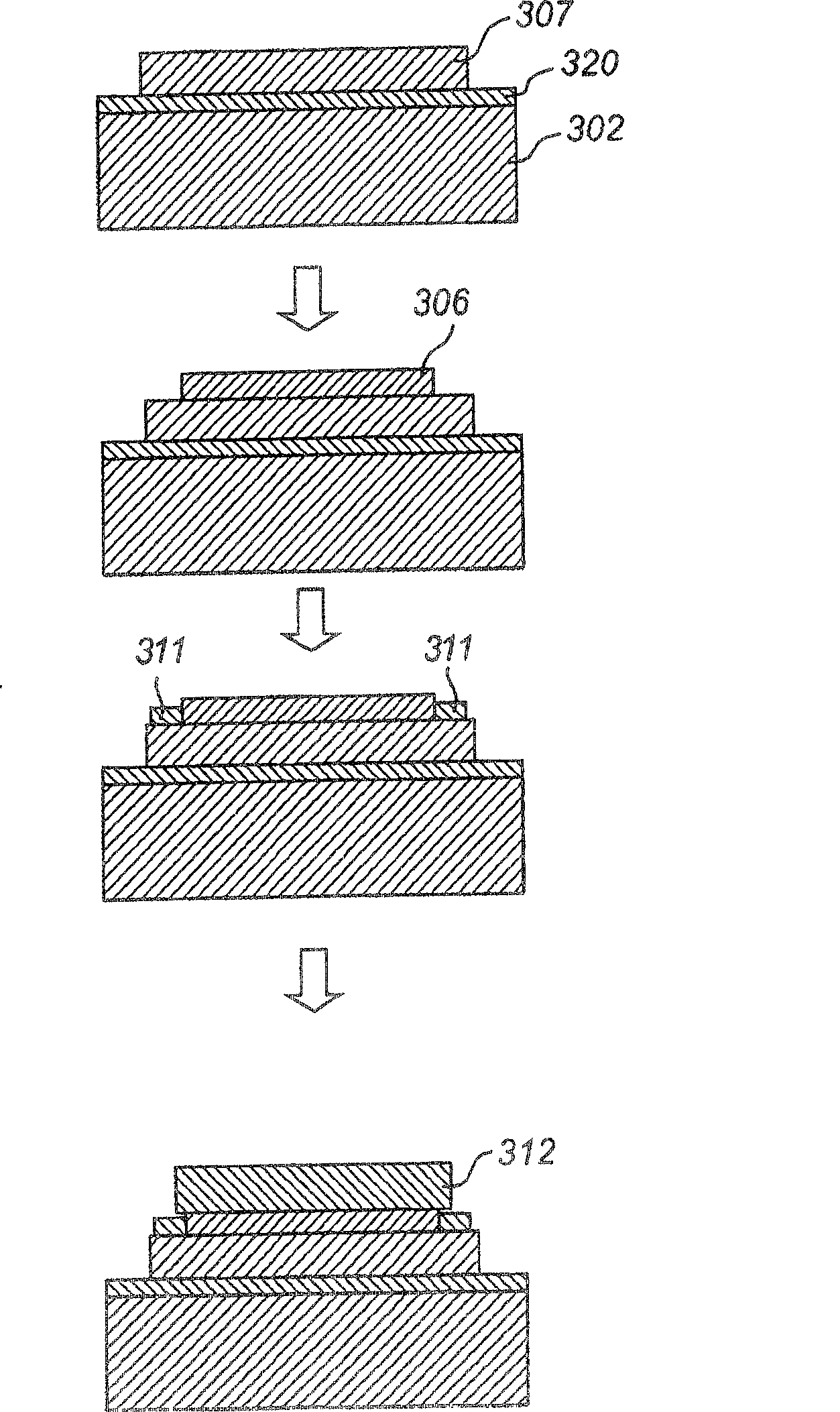

[0017] Semiconducting wires and carbon nanotubes can be grown by employing well-known vapor-liquid-solid (VLS) processes. This process is typically performed at a temperature in the range of 400 to 800°C. The VLS process uses small metal particles as nuclei for further growth. When using sufficiently small metal particles, the wire diameter can be made less than 10nm. As an alternative, semiconducting wires and metals can be deposited in suitable templates by electrochemical processes at room temperature. In either process, or a combination of both processes, segments of wires composed of, for example, n- and p-type semiconductor materials or exhibiting heterojunctions may be grown. Appropriate stencils can be used when high density semi-conductive lines are required. Electrochemical oxidation (ie, anodization) of aluminum is known to produce highly regular porous alumina when suitable conditions prevail. Typically, the holes are perpendicular to the surface of the substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com