High-performance electrochromic capacitor bifunctional device and manufacturing method thereof

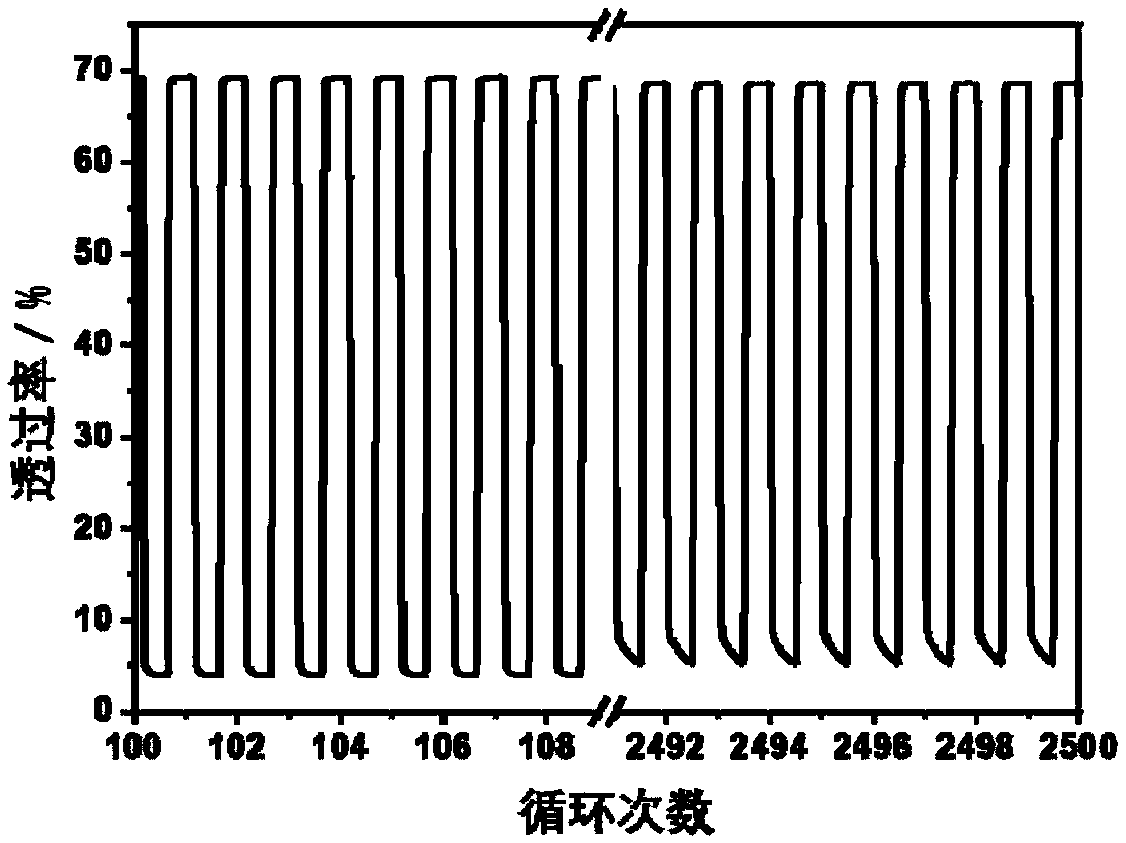

An electrochromic and capacitor technology, applied in instruments, nonlinear optics, optics, etc., can solve the problems of insignificant color change during charging and discharging, poor cycle stability, etc., and achieve the effect of high specific capacitance and high color contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

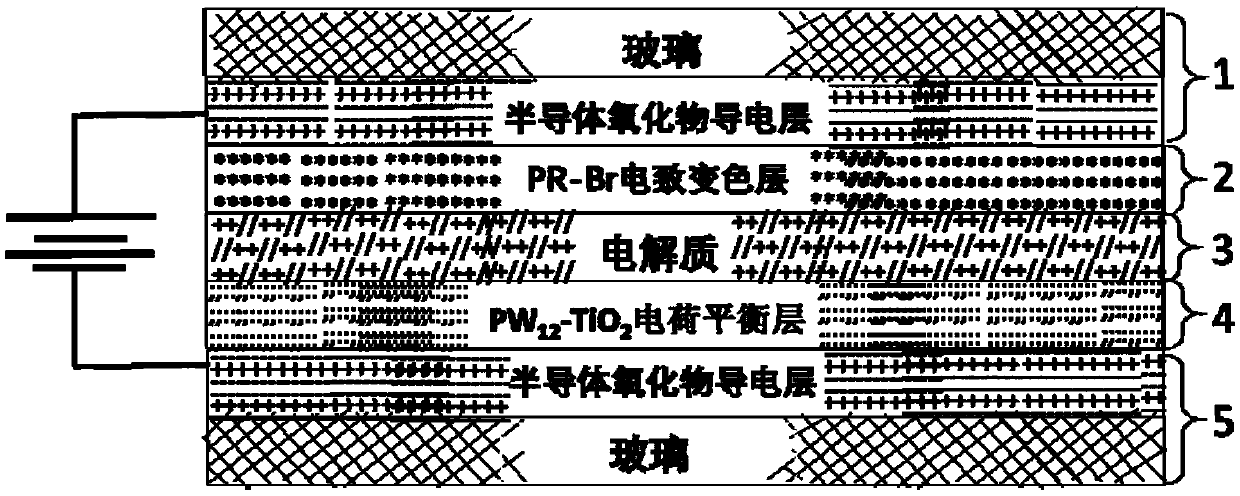

[0037] (1) Preparation method

[0038] 1. Preparation of working electrode:

[0039] Sequentially add 0.3g FeCl 3 ·6H 2 O, 0.2g polyoxypropylene polyoxyethylene copolymer (molecular weight 2800g mol -1 ) and 0.05g 3,4-(2',2'-bis(bromomethyl)propylenedioxythiophene (structural formula such as Figure 2a shown) were dissolved in 0.8 g butanol and sonicated for 5 min at room temperature. Then, the resulting mixed solution was filtered through a hydrophilic syringe filter, and evenly coated on the ITO conductive glass substrate by the spin coating method, and the rotation speed was controlled to be 1000rpm and the spin coating time was 10s to obtain a 180nm thick polymer film. Wash off residual FeCl with ethanol 3 After blowing dry with nitrogen, the FTO conductive glass loaded with polymer film (PR-Br) was obtained as the working electrode.

[0040] 2. Production of the counter electrode:

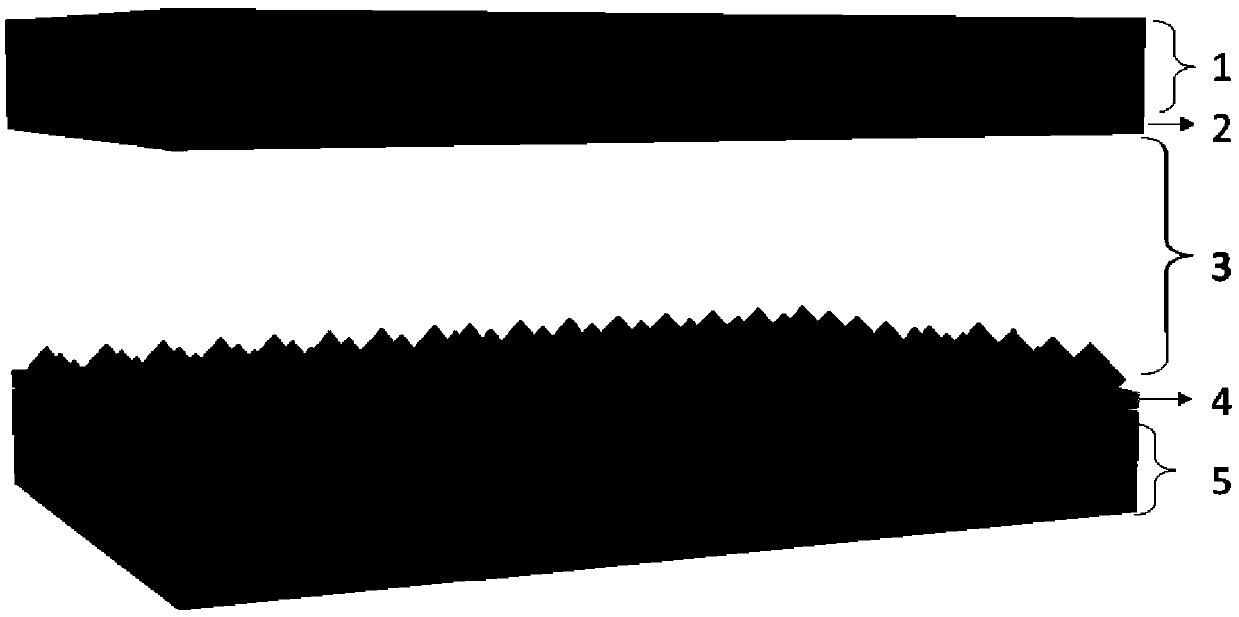

[0041] 2.1) Using commercial TiO 2 Slurry (purchased from Greatcell company, speci...

Embodiment 2

[0048] (1) Preparation method

[0049] 1. Preparation of working electrode:

[0050] Sequentially add 0.3g FeCl 3 ·6H 2 O, 0.2g polyoxypropylene polyoxyethylene copolymer (molecular weight 2800g mol -1 ) and 0.05g 3,4-(2',2'-bis(bromomethyl)propylenedioxythiophene (structural formula such as Figure 2a shown) were dissolved in 0.8 g butanol and sonicated for 5 min at room temperature. Then, the resulting mixed solution was filtered through a hydrophilic syringe filter, and evenly coated on the ITO conductive glass substrate by the spin coating method. The control rotation speed was 1100rpm and the spin coating time was 10s to obtain a 175nm thick polymer film. Wash off residual FeCl with ethanol 3 After blowing dry with nitrogen, the ITO conductive glass loaded with polymer film (PR-Br) was obtained as the working electrode.

[0051] 2. Production of the counter electrode:

[0052] 2.1) Using commercial TiO 2 Slurry (purchased from Greatcell company, specification: TiO...

Embodiment 3

[0059] (1) Preparation method

[0060] 1. Preparation of working electrode:

[0061] Sequentially add 0.3g FeCl 3 ·6H 2 O, 0.2g polyoxypropylene polyoxyethylene copolymer (molecular weight 2800g mol -1 ) and 0.05g 3,4-(2',2'-bis(bromomethyl)propylenedioxythiophene (structural formula such as Figure 2a shown) were dissolved in 0.8 g butanol and sonicated for 5 min at room temperature. Then, the resulting mixed solution was filtered through a hydrophilic syringe filter, and evenly coated on the ITO conductive glass substrate by the spin coating method. The rotation speed was controlled to 1400 rpm and the spin coating time was 10s to obtain a 160nm thick polymer film. Wash off residual FeCl with ethanol 3 After blowing dry with nitrogen, the ITO conductive glass loaded with polymer film (PR-Br) was obtained as the working electrode.

[0062] 2. Preparation of counter electrode:

[0063] 2.1) Using commercial TiO 2 Slurry (purchased from Greatcell company, specification:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com