Method for producing stainless steel powder containing nitrogen high nitrogen by adopting gas atomization method

A high-nitrogen stainless steel, gas atomization technology, applied in the field of powder metallurgy, can solve the problems of difficult nitrogen content, high production cost, expensive and complicated equipment, etc., and achieve the effect of controllable nitrogen content, high production efficiency and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

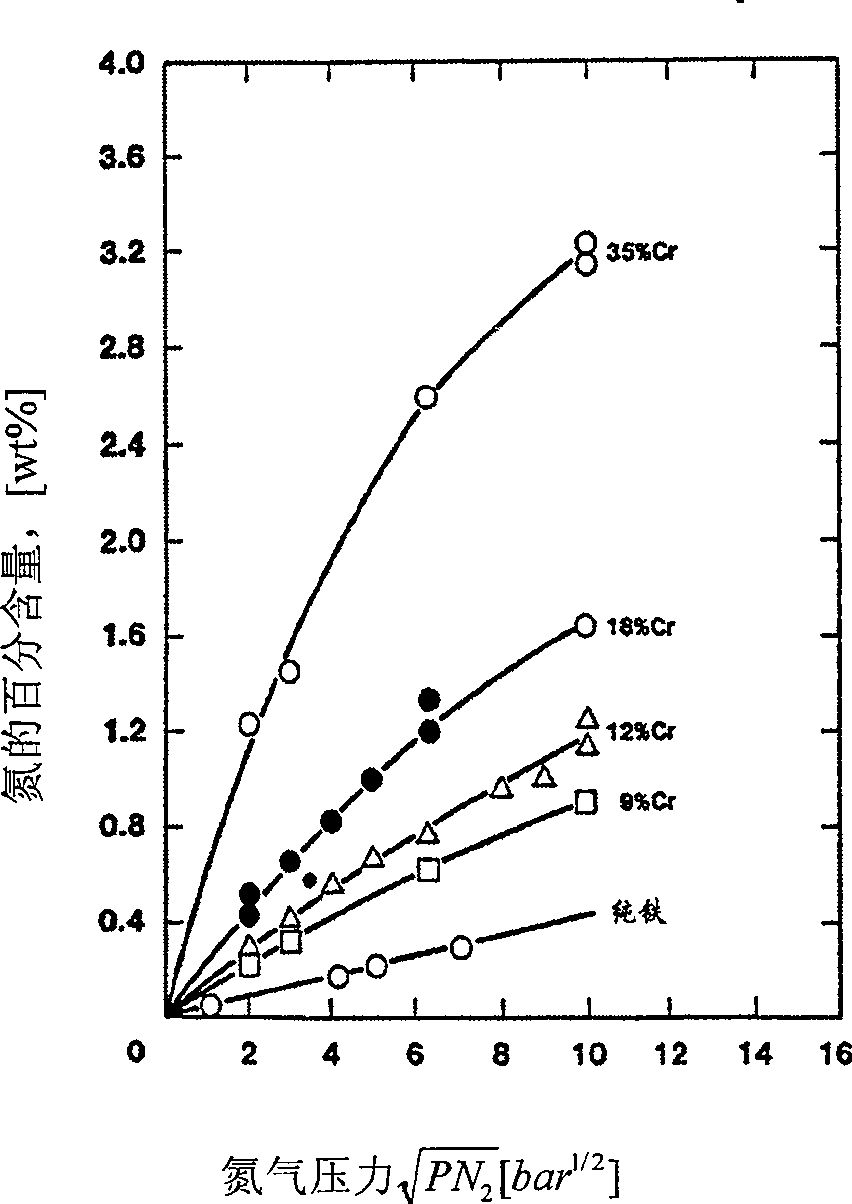

[0038] Embodiment 1: Preparation of high-nitrogen nickel-free stainless steel powder

[0039] Use 19.73kg of Fe, 3.92kg of Cr, 0.62kg of Mo, 3.72kg of Mn, and 0.12kg of Si as raw materials in a smelting furnace, and take 2.07kg of high nitrogen alloy [FeCrN] for secondary feeding In the container, vacuum to 10 -2 Pa, filled with nitrogen to 0.07MPa (the same under absolute pressure), energized until the temperature of the molten steel is 1520°C and kept warm for 15 minutes, then added high-nitrogen alloy in 2 times, the average particle size of high-nitrogen alloy particles is 15mm, and the temperature was raised to Atomization starts at 1650°C, and the atomization pressure is 3MPa. After the powder is cooled in the atomization furnace, it is sieved and vacuum packed. After testing and analysis, the nitrogen content is 0.46%.

Embodiment 2

[0040] Embodiment 2: Preparation of high-nitrogen nickel-containing stainless steel powder

[0041]Use 14.76kg of Fe, 6.56kg of Cr, 0.62kg of Mo, 1.86kg of Mn, 0.10kg of Si, and 3.01kg of Ni as raw materials in a smelting furnace, and take 3.19kg of high-nitrogen alloy [FCrN] Put in the secondary feeder, vacuum to 10 -2 Pa, when the temperature of the molten steel is 1520°C, fill nitrogen to 0.07MPa (the same under absolute pressure), keep warm for 15 minutes, add high-nitrogen alloy in 3 times, the average particle size of high-nitrogen alloy particles is 15mm, and heat up to Atomization starts at 1700°C, and the atomization pressure is 3MPa. After the powder is cooled in the atomization furnace, it is sieved and vacuum packed. After testing and analysis, the nitrogen content is 0.76%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com