Rolling friction joint suspended-dome structure and construction method thereof

A rolling friction, chord-supported dome technology, applied in the dome-roof structure, arched structure, roof and other directions, can solve the problems of inconsistency in the size distribution of internal force with the design, adverse effects on the mechanical properties of the chord-supported dome structure, and uneven tension, etc. The effect of enhanced self-adjustment function, high construction efficiency and reduced construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

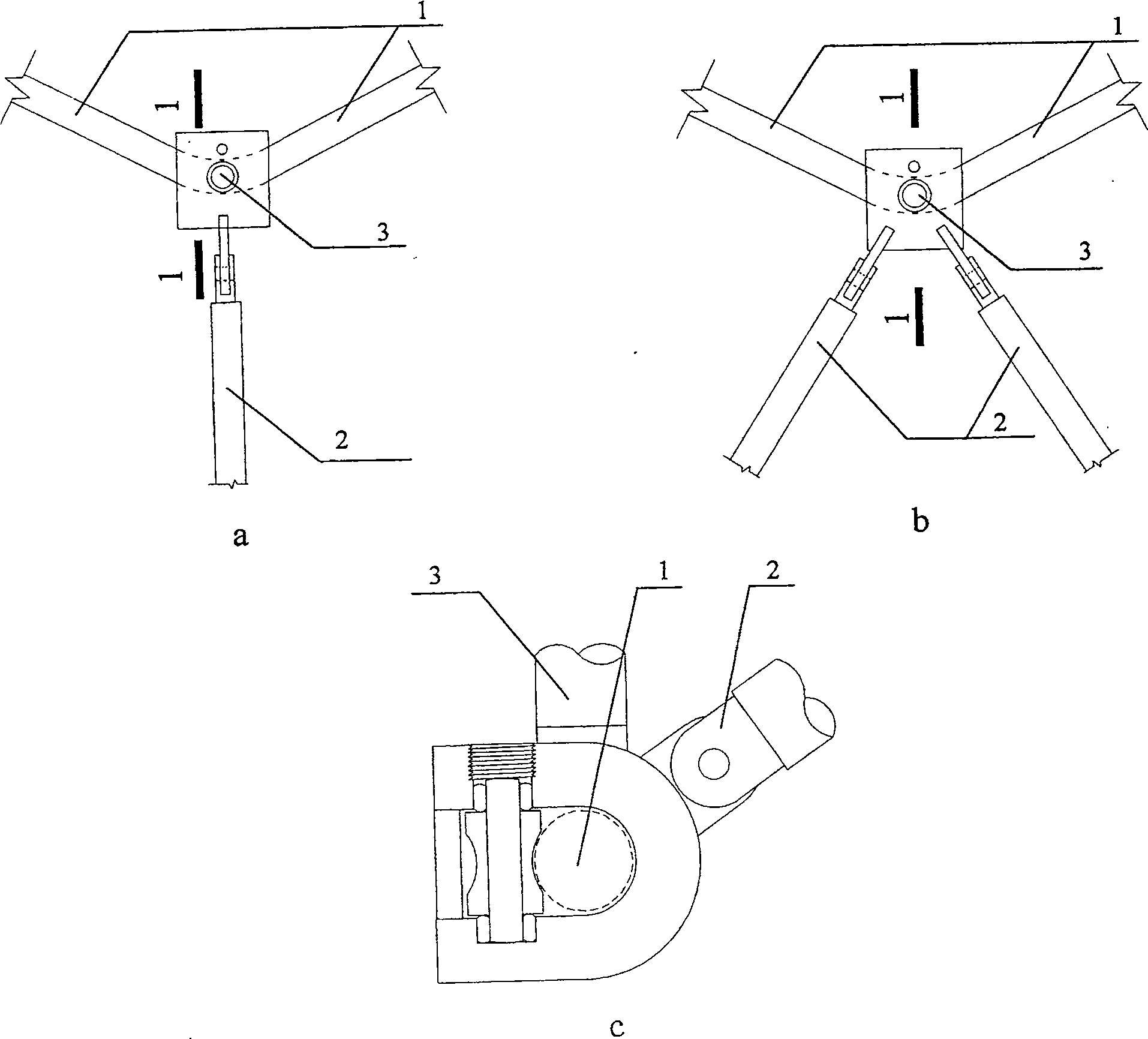

[0034] Such as image 3 As shown in b and 3c, the described node is a rolling friction type I node, including a vertical rod 3, two warp rods 2, a U-shaped steel plate 4 placed horizontally and a hollow concave ring 10; the top of the U-shaped steel plate 4 There are screw holes 6, the bottom of the U-shaped steel plate 4 is a non-through hole, the upper surface of the U-shaped steel plate 4 is welded with the pole base 7, the pole base 7 is welded with the vertical pole 3, and the arc-shaped surface of the U-shaped steel plate 4 is welded 2 Ear plates 8, each ear plate 8 is rotatably connected with the respective warp rods 2, the hollow concave ring 10 is installed in the U-shaped steel plate 4, and the cylindrical shaft 11 is directly inserted from the U-shaped steel plate 4 through the hollow concave ring 10 To the dead hole below the U-shaped steel plate 4, the middle part of the cylindrical shaft 11 is an interference fit with the hollow concave ring 10, and the two ends ...

Embodiment 2

[0041] Such as Figure 6 As shown, the node is a rolling friction II type node, including vertical rods 3, 2 warp rods 2, and a T-shaped round platform 15; Concave circular ring 10', L-shaped safety protection steel plate 19, T-shaped round table 15 upper plane respectively welded with 2 ear plates 8 rotationally connected with warp rod 2 and ear plate 18 rotationally connected with a vertical pole 3, the ring The cable 1 penetrates into the L-shaped safety protection steel plate 19 and the concave ring 10', and the circular cable 1 forms a sliding fit with the concave ring 10'.

[0042] The manufacturing process of the rolling friction type II node is as follows: Figure 7 a, 7b, 7c, 7d, 7e. Process it into a T-shaped round table 15 by casting or cutting process; Drill the bottom screw hole 16 at the protruding part of the T-shaped round table 15; Drill the side screw hole 17 on the side of the T-shaped round table 15; Weld the ear plate 18 of the vertical rod; The ear pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com