Evaporating fuel gas leak detection device

A gas leakage detection and detection device technology, which is applied in the direction of measuring devices, charging systems, engine components, etc., can solve the problems of long detection time, leakage, and long detection time of evaporative combustible gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiment 1

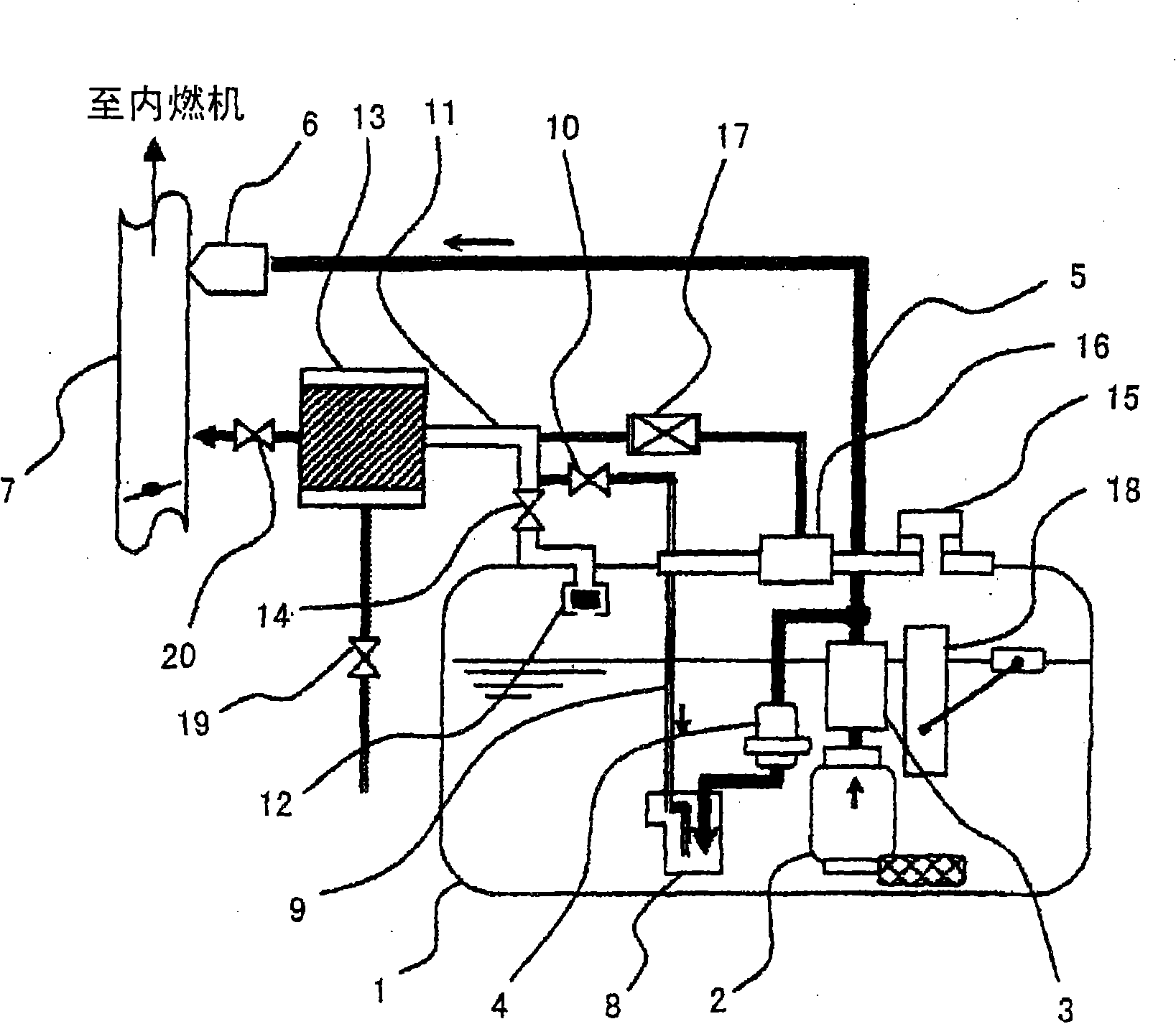

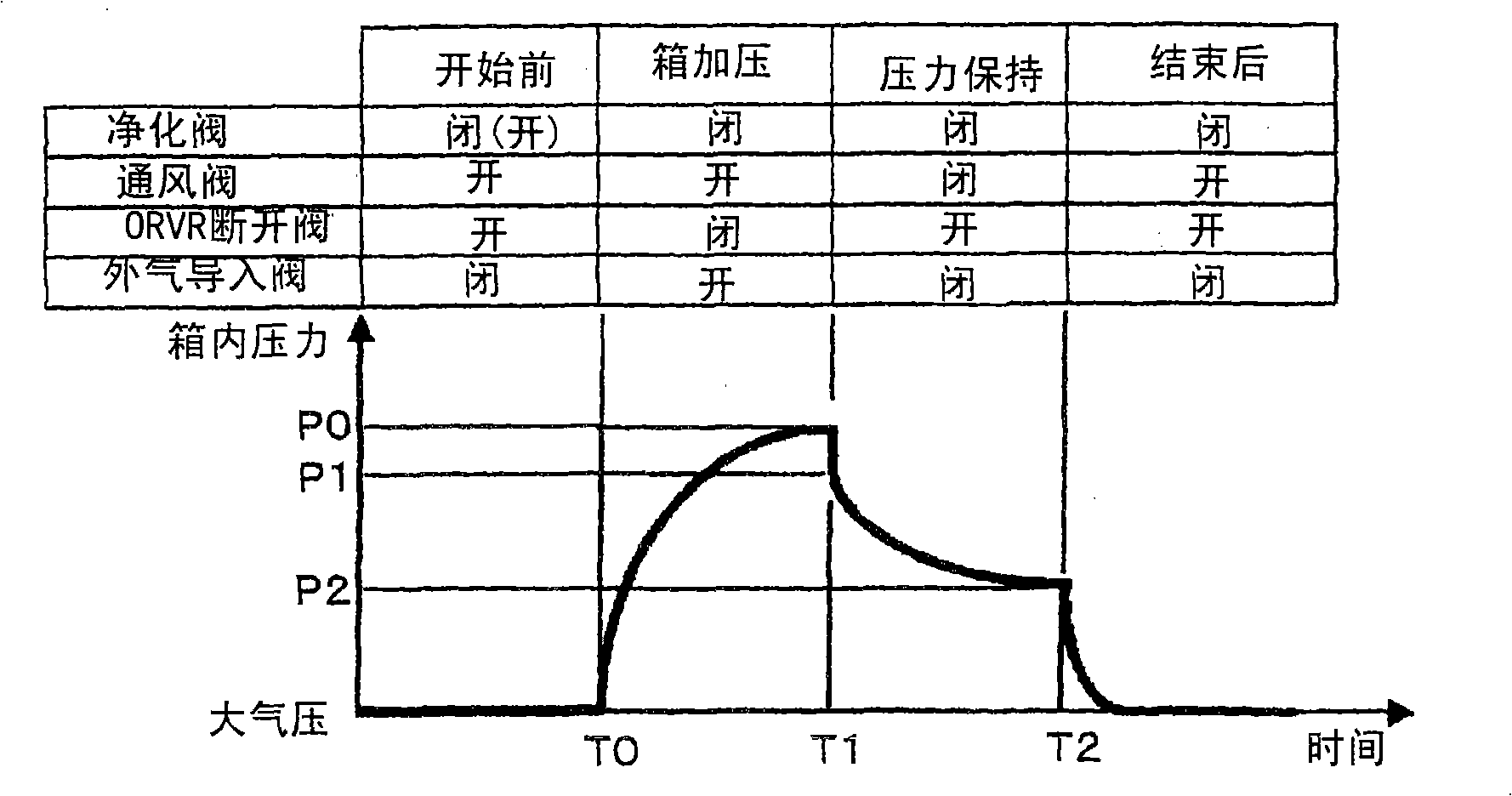

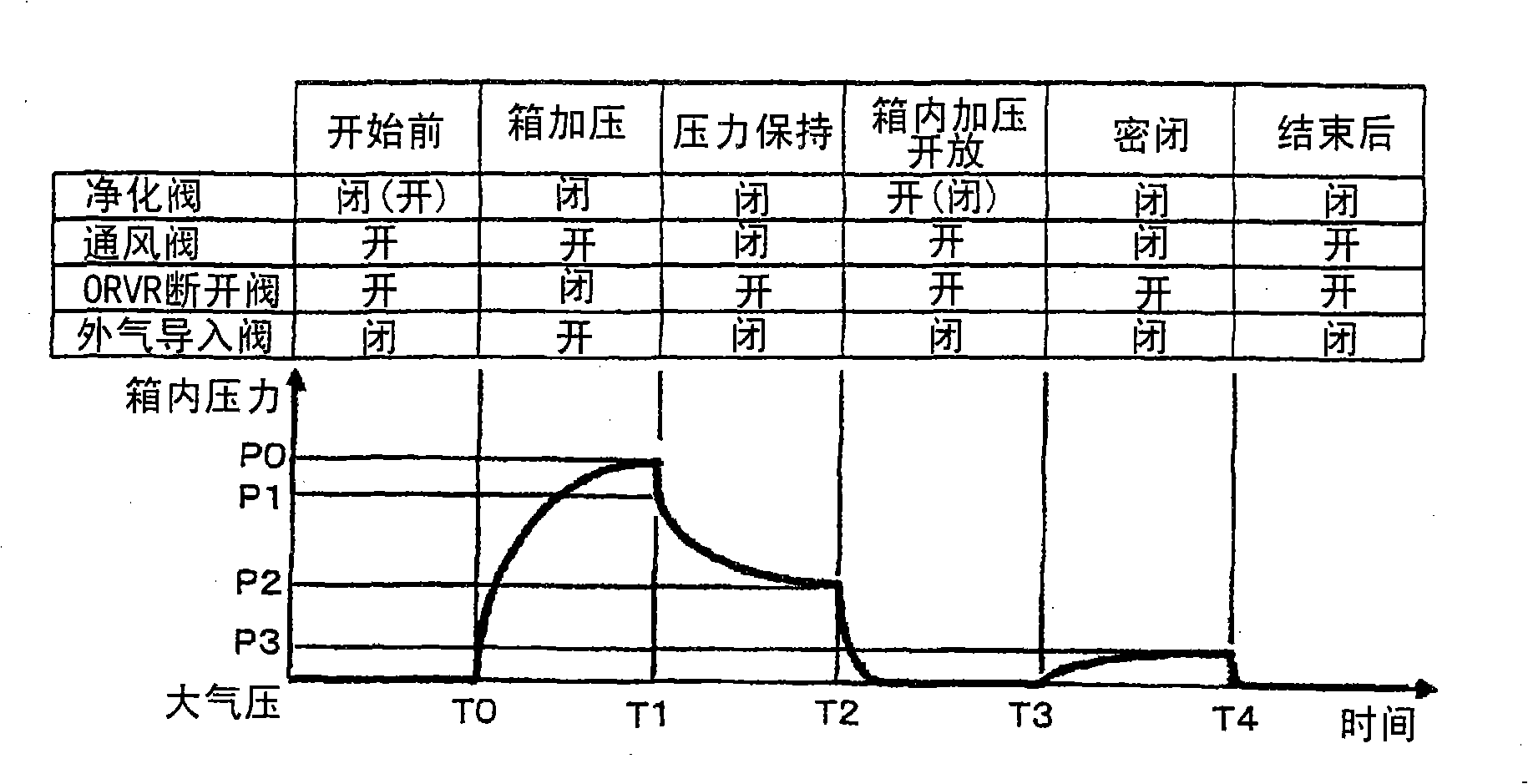

[0018] figure 1 It is a structural diagram of an evaporative combustible gas leakage detection device in Embodiment 1 of the present invention, figure 2 It is a graph showing the opening and closing sequence of the closing control valve of the evaporation purification system and the time change of the pressure in the fuel tank.

[0019] figure 1 In the fuel tank 1, the gasoline supplied from the fuel pump 2 is filtered by the fuel filter 3, adjusted to a certain pressure by the pressure regulator 4, supplied to the injector 6 through the fuel pipe 5, and injected from the injector 6 to The intake manifold 7 is then combusted in an internal combustion engine not shown.

[0020] An injection pump 8 serving as a pressurizing device in the fuel tank 1 is provided at a discharge port of the pressure regulator 4 branched from the fuel pipe 5 . One end of the outside air introduction pipe 9 is connected to the jet pump 8 , and the other end of the outside a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com