Exposal machine carrying platform cleaning method and system

A technology for a film carrier and a film table is applied in the field of cleaning methods and systems for a film carrier of an exposure machine, which can solve the problems of wasting time and the like, and achieve the effects of high cleaning efficiency, time saving and utilization rate improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

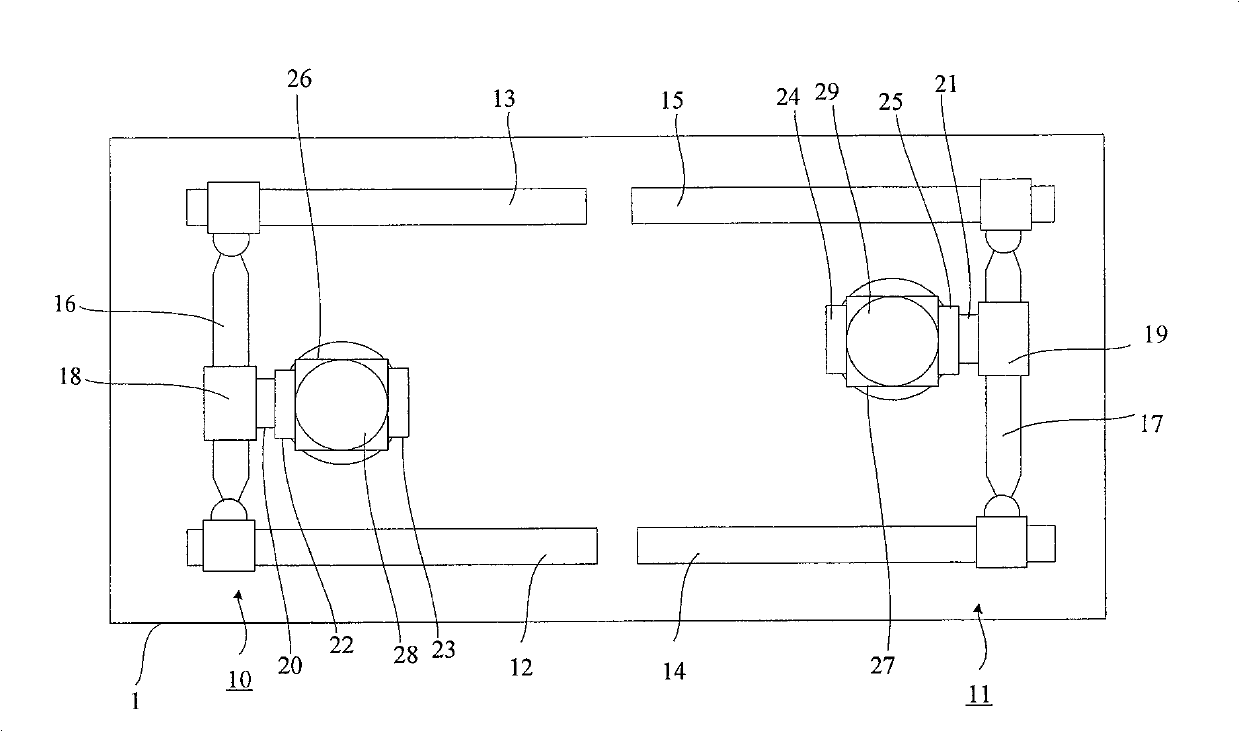

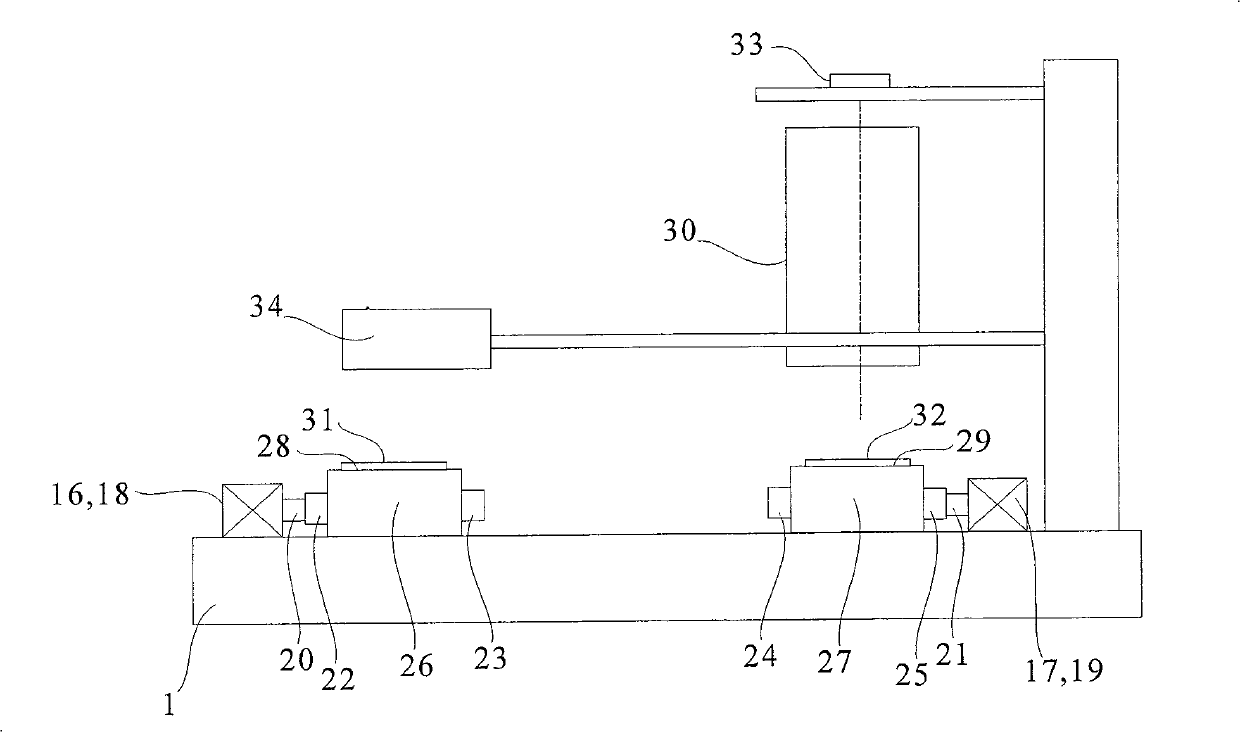

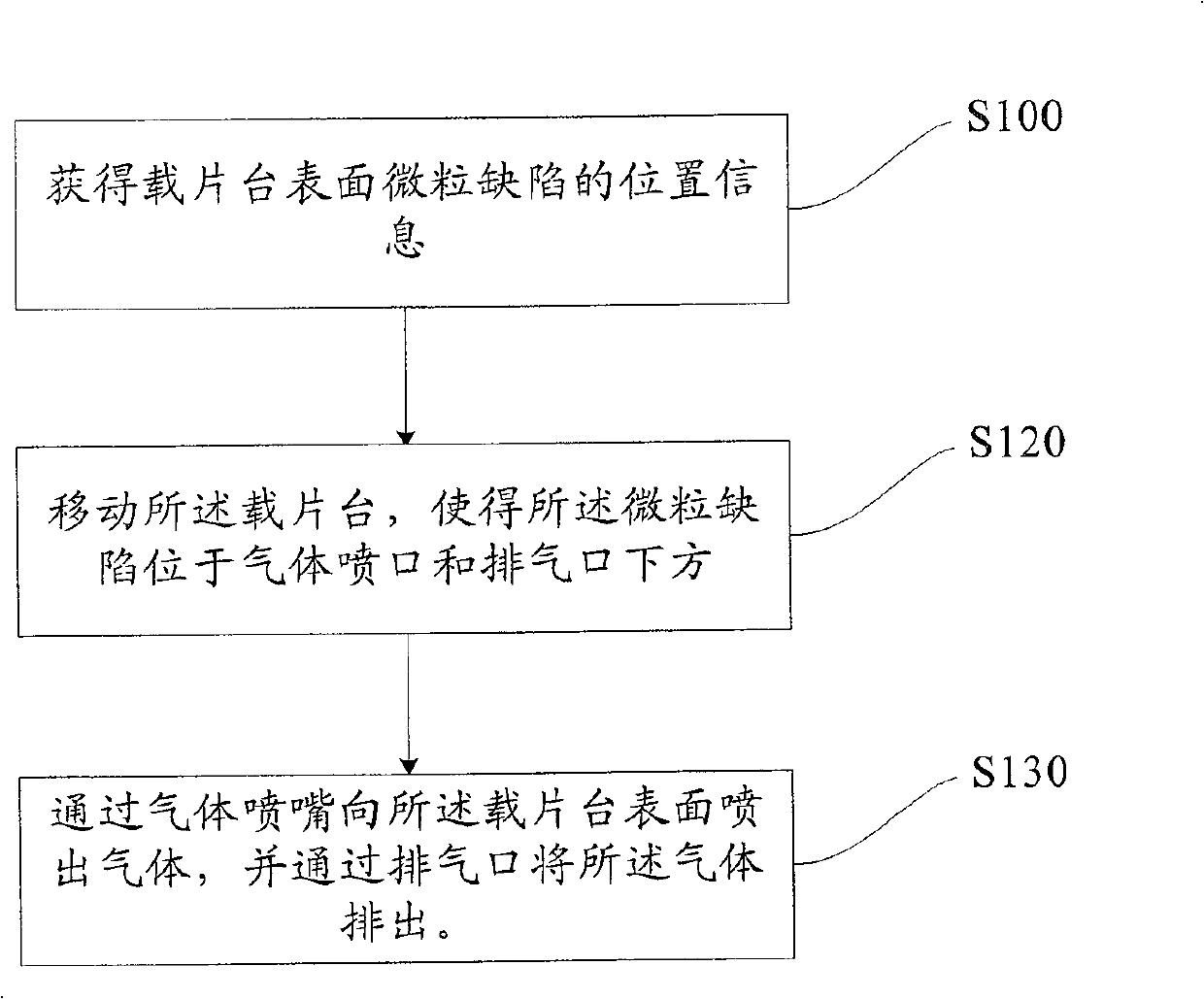

[0035] The invention discloses a method for cleaning the surface of the loading table of an exposure machine. The method judges the position information of particle defects on the surface of the loading table through the surface fluctuation information of the wafer on the loading table obtained during the exposure process, and according to the The position information moves the loading table so that the particle defects are located below the gas nozzle and the exhaust port, and the gas is ejected to the surface of the loading table through the gas nozzle, and the airflow of the ejected gas blows the The particle defects on the loading table are removed, and the gas with particle defects is discharged through the exhaust port. The metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com