Hydrogen production apparatus, method of operating hydrogen production apparatus, fuel cell system and method of operating fuel cell system

A generation device and generator technology, applied in the direction of fuel cells, fuel cell additives, chemical instruments and methods, etc., can solve problems that hinder the rise and stability of reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

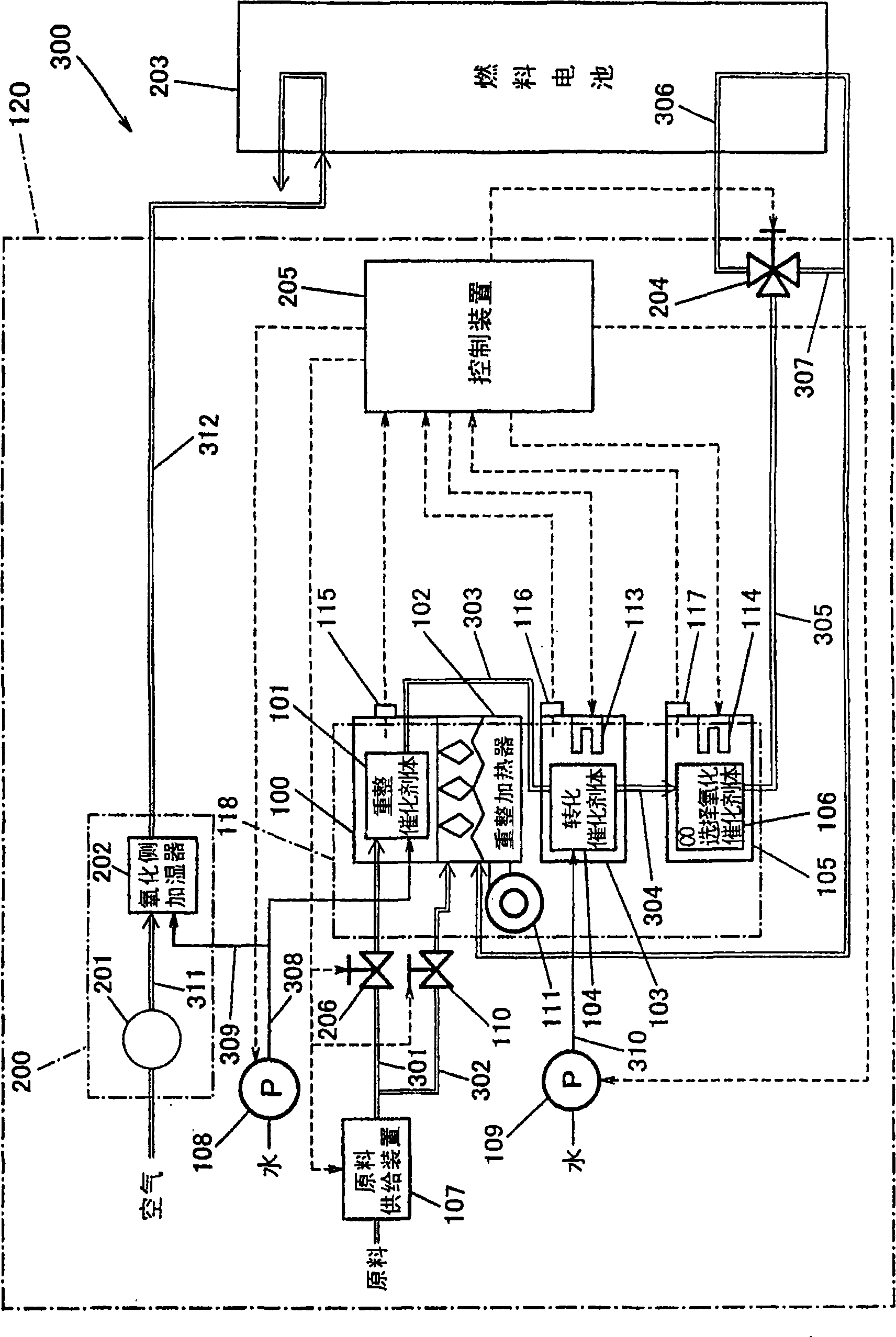

[0094] figure 1 It is a block diagram showing a configuration example of the fuel cell system according to Embodiment 1 of the present invention.

[0095] The hydrogen generating device 120 is mainly composed of a hydrogen generator 118 that supplies hydrogen-rich gas (hereinafter referred to as hydrogen-rich gas) to the combustion cell 203; controls the supply of hydrocarbon raw materials such as methane, butane, and natural gas, and simultaneously detects the hydrogen generator. The temperature of the reformer 103 and / or the selective oxidizer 105 of 118, the control device 205 that detects and determines whether there is abnormality in the amount of water or water vapor; the oxidant gas supply device 200 that supplies air as an oxidant to the fuel cell 203; The generator 118 is composed of a raw material supply device 107 for supplying raw materials; and first and second water supply devices 108 and 109 for supplying water to the hydrogen generator 118 .

[0096] Further, ...

Embodiment approach 2

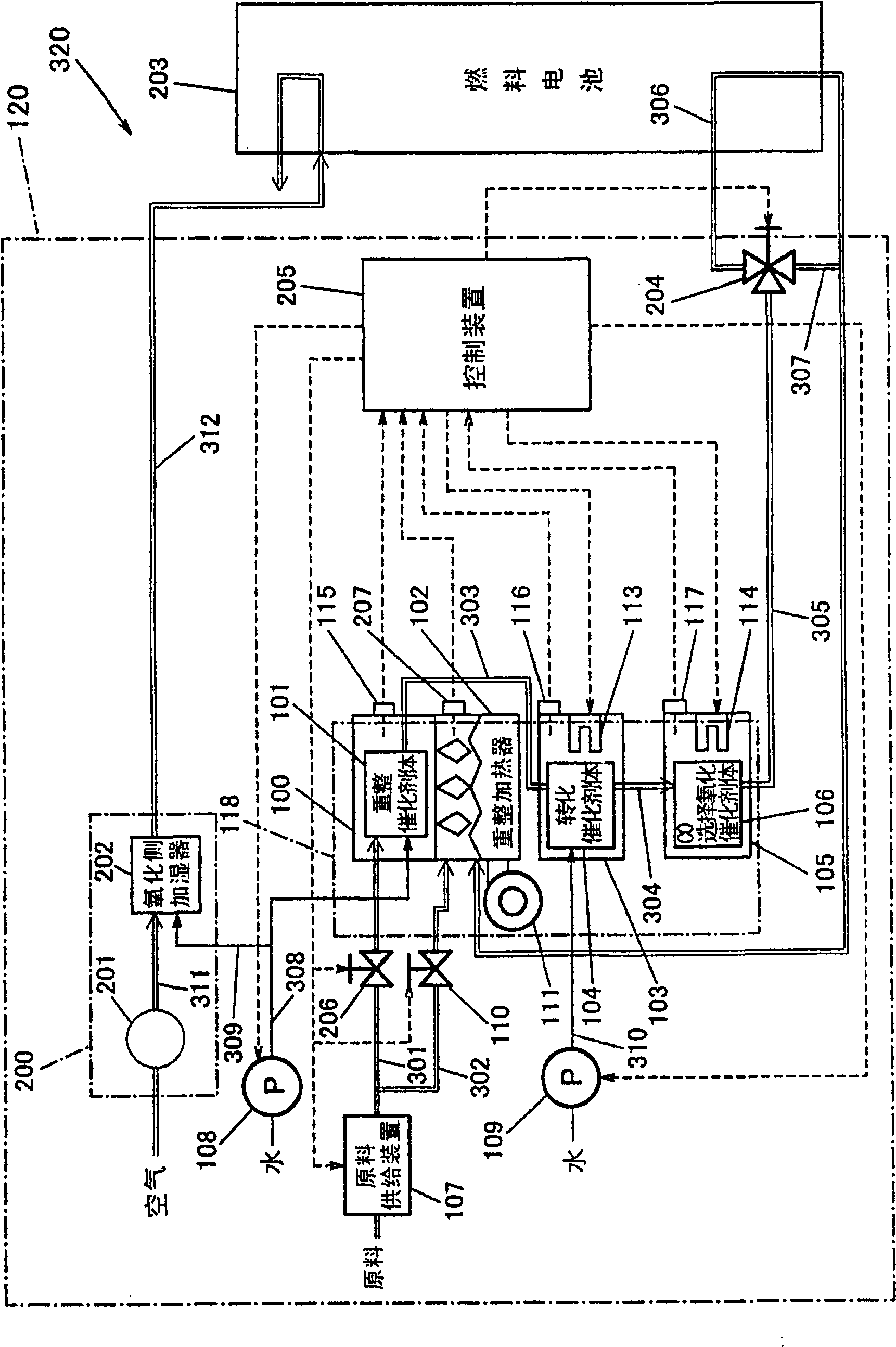

[0143] image 3 It is a block diagram showing a configuration example of a fuel cell system according to Embodiment 2 of the present invention.

[0144] The structure of the fuel cell system 320 of the present embodiment is the same as that of the combustion cell system 320 of the first embodiment, except that the reforming heater 102 is provided with the combustion detector 207 for detecting the combustion state of the combustible gas by the reforming heater 102. The structure of the system 300 is the same.

[0145] Also, in Embodiment 1, an example was described in which it is determined whether the amount of water or water vapor inside the hydrogen generator 118 is excessive based on the detected temperatures detected by the reformer temperature detection unit 116 and the selective oxidizer temperature detection unit 17. In the embodiment of the invention, it is also possible to determine whether the amount of water or the amount of water vapor inside the hydrogen generato...

Embodiment approach 3

[0182] Figure 7 It is a block diagram showing a configuration example of a fuel cell system according to Embodiment 3 of the present invention. In this embodiment, a description will be given of a first modification aimed at removing excess water inside the reformer 103 or the selective oxidizer 105 .

[0183] The configuration and operation of the hydrogen generator 118, the oxidant gas supply device 200, the fuel cell 203, and the control device 205 are the same as those described in Embodiments 1 and 2, and thus the description thereof will be omitted.

[0184] The change in the structure of the fuel cell system 330 of the present embodiment is that a reformer discharge valve 400 for discharging excess condensed water stagnated inside the reformer 103 due to the influence of excess water vapor and the like is connected to the reformer 103, and the The selective oxidizer discharge valve 401 for discharging the excess condensed moisture stagnated in the selective oxidizer 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com