Method for preparing epoxide

A technology of epoxides and organic peroxides, applied in chemical instruments and methods, chemical/physical processes, organic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

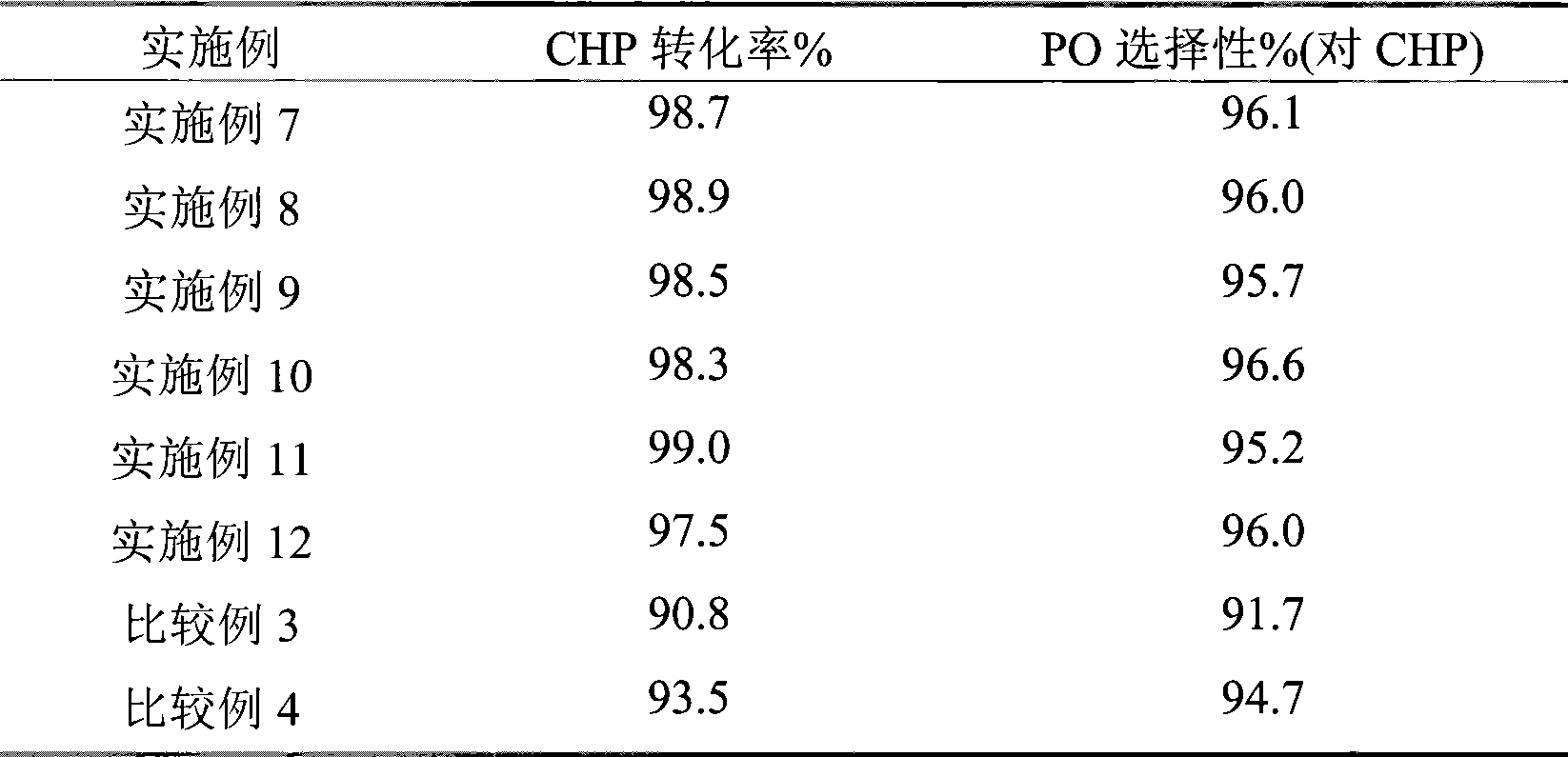

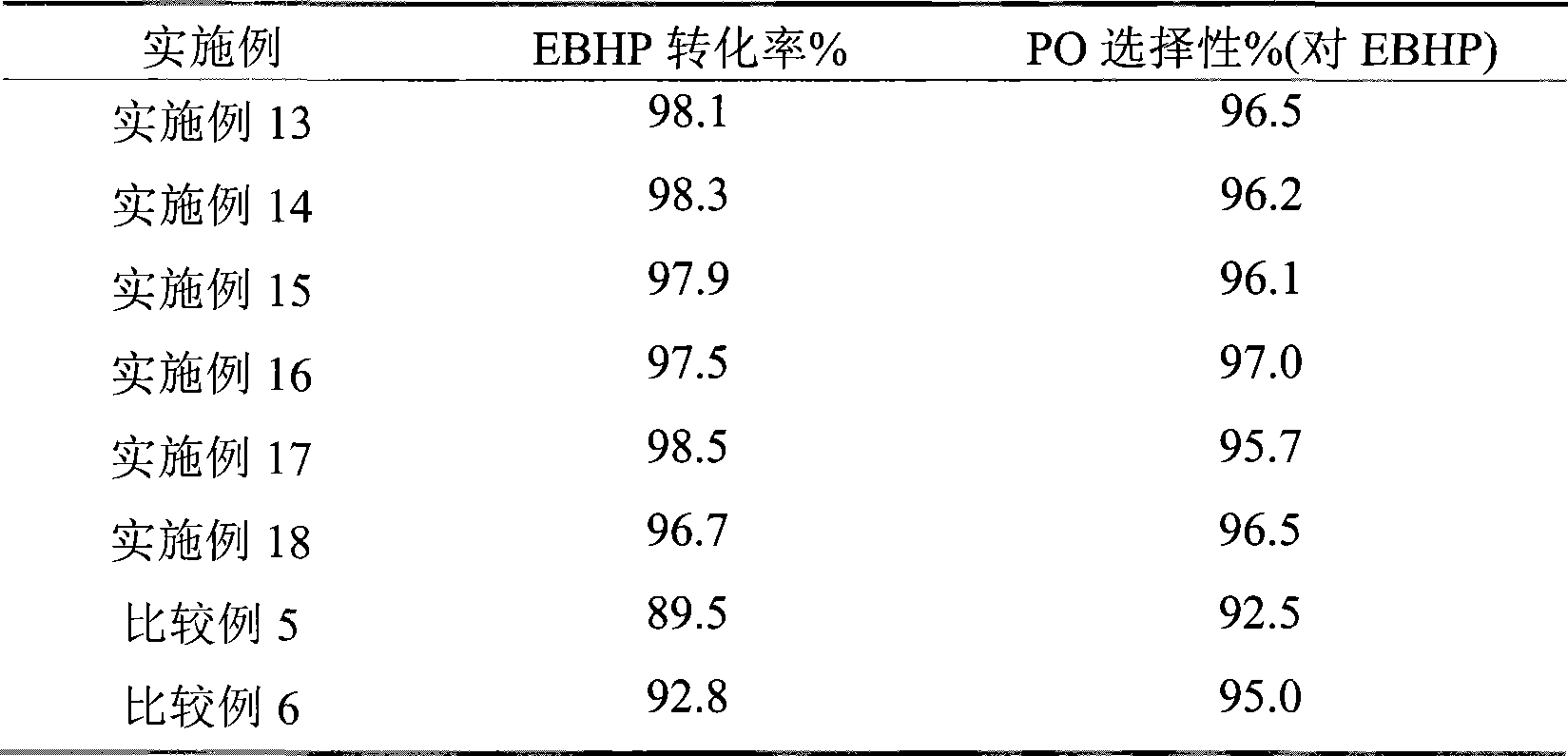

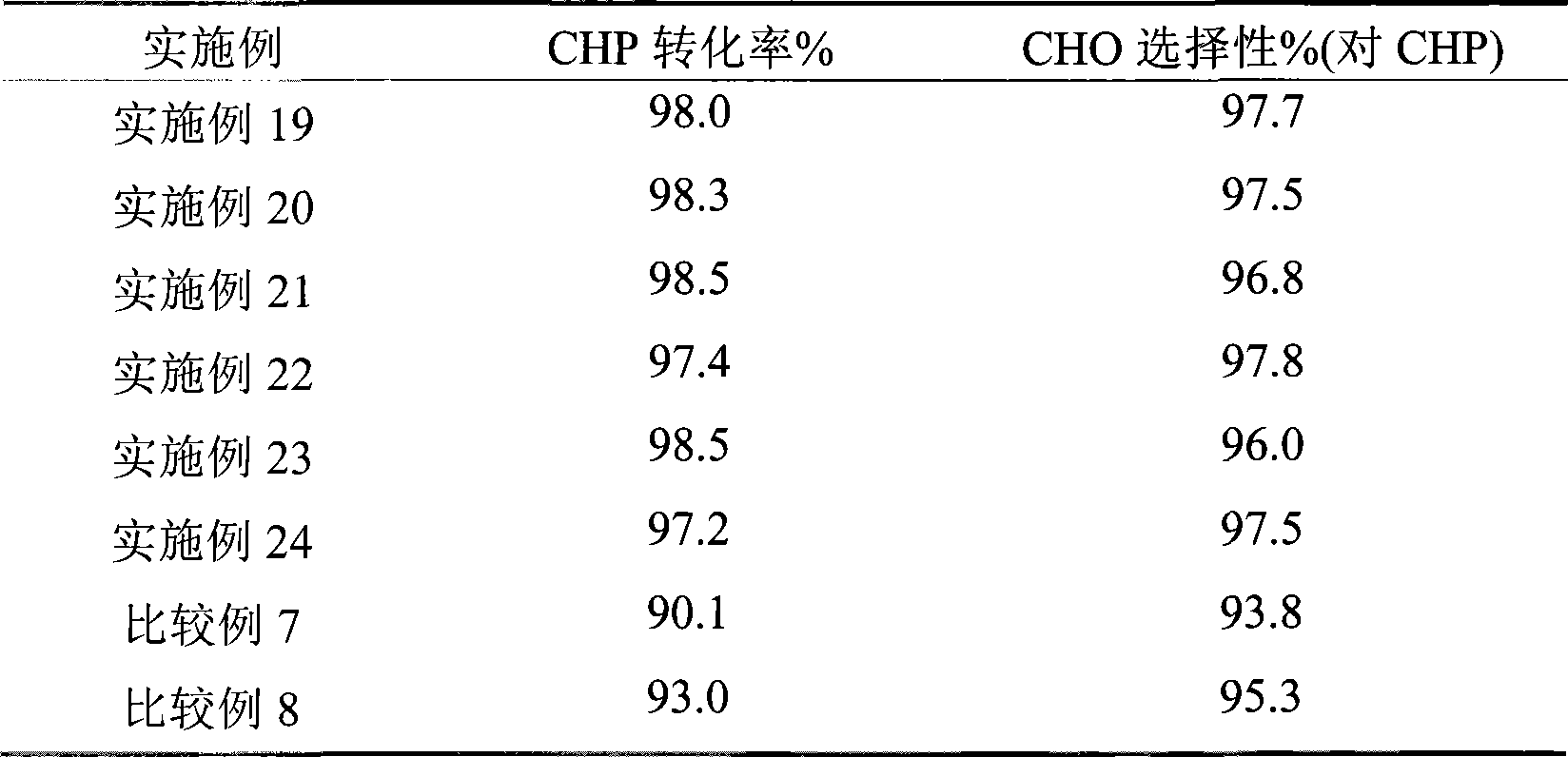

Examples

Embodiment 1

[0020] Dissolve 16.0 g of hexadecylamine in 80 mL of H 2O. In a mixed solution of 60 milliliters of ethanol and 5 milliliters (1 mol / liter) of hydrochloric acid, stir until the solution is one phase. 50.0 grams of ethyl orthosilicate dissolved in 30 milliliters of ethanol, 10.6 grams of diethyl dimethyl silicate and 4.0 grams of tetrabutyl titanate dissolved in 10 milliliters of ethanol were simultaneously added to the above mixed solution, and After stirring for 30 minutes, it crystallized for 24 hours. Then filter the obtained solid, put the filtered solid into an ion exchange column, and carry out vacuum extraction with ethanol solvent to remove the template agent therein. After extraction, it was washed three times with distilled water, and then vacuum-dried at 60° C. to obtain the catalyst precursor. Add 50 milliliters of cumene solutions containing 4.0 grams of hexamethyldisilazane in a 100 milliliter three-necked flask, add 10.0 grams of the catalyst precursor prepare...

Embodiment 2

[0022] Except that 10.6 grams of diethyl dimethyl silicate in [Example 1] was replaced by 8.5 grams of dimethyl dimethyl silicate, the rest of the conditions were the same as in [Example 1]. The finished Ti-HMS catalyst thus prepared has a specific surface area of 920 m 2 / g, the pore volume is 0.95 cm 3 / g, the average pore diameter is

Embodiment 3

[0024] Except that the amount of tetrabutyl titanate is 5.0 g, other conditions are the same as [Example 1]. The finished Ti-HMS catalyst thus prepared has a specific surface area of 900 m 2 / g, the pore volume is 0.90 cm 3 / g, the average pore diameter is

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com