Passivating device for high-temperature Fischer-Tropsch synthesis of waste catalyst

A waste catalyst, Fischer-Tropsch synthesis technology, used in catalyst protection, physical/chemical process catalysts, preparation of liquid hydrocarbon mixtures, etc. The effect of lowering temperature and reducing catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

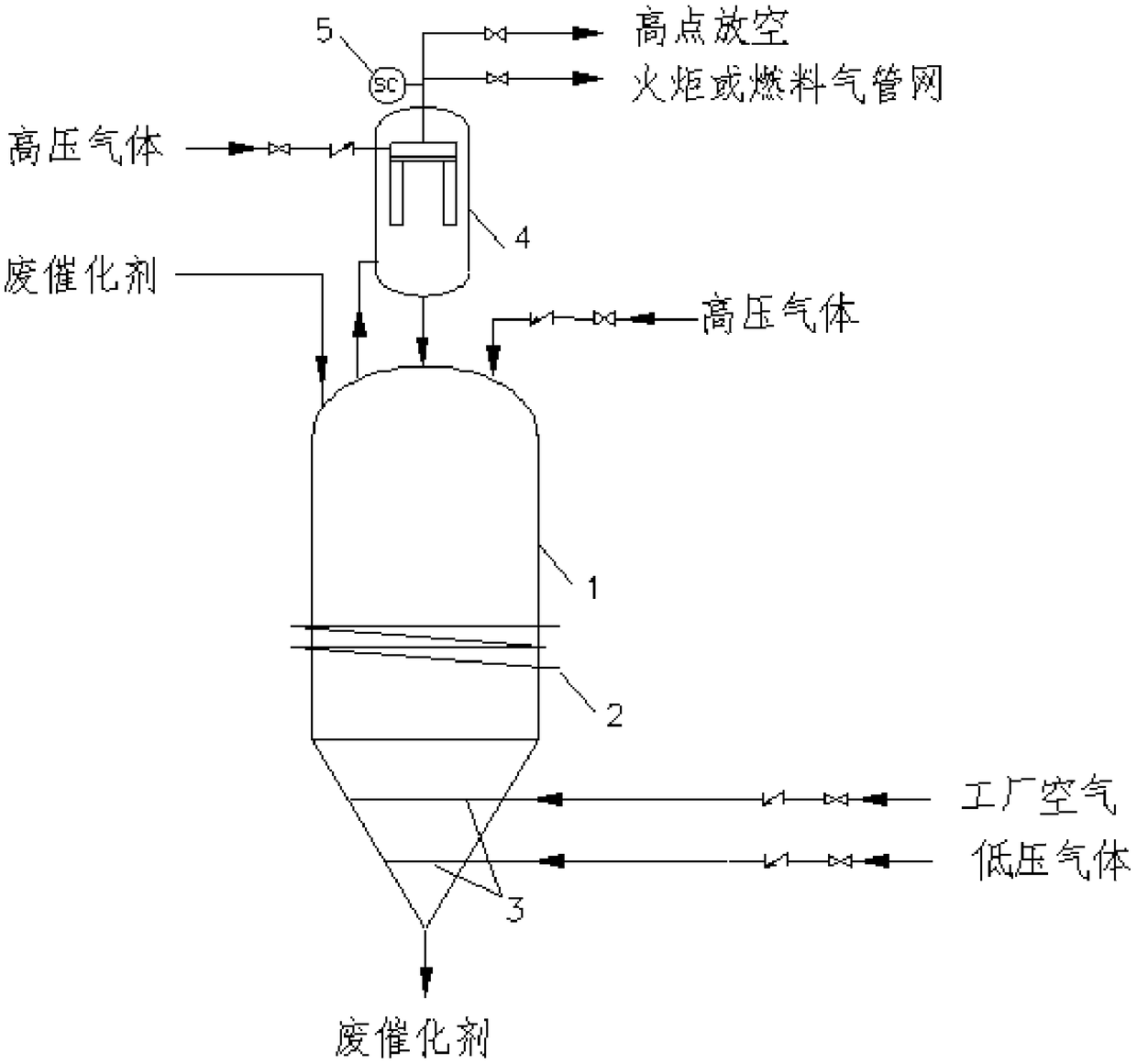

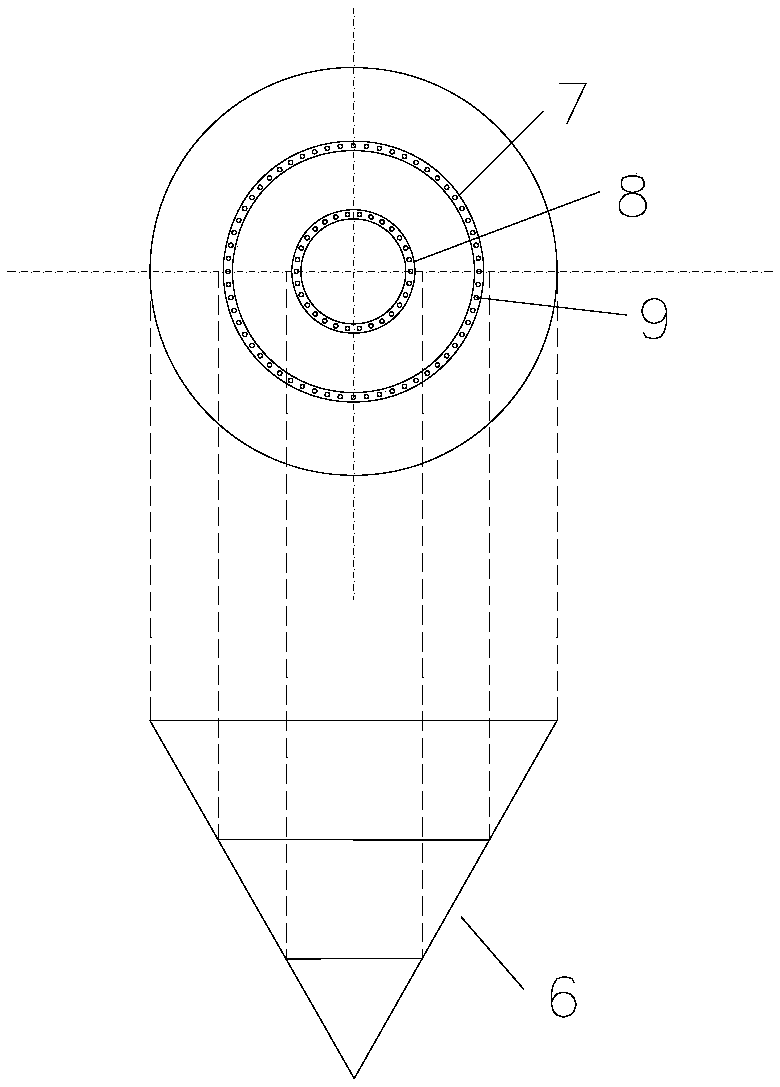

[0029] A high-temperature Fischer-Tropsch synthesis waste catalyst passivation device, its structure is as follows figure 1 As shown, it includes a spent catalyst collection tank 1 and a gas-solid separator 4 connected to the top of the spent catalyst collection tank 1 . The inner angle of the cone bottom 6 of the spent catalyst collection tank 1 is 60°, and the cone bottom is provided with a two-layer gas distributor 3, such as figure 2shown. Counting from top to bottom, what passes into the first layer of gas distribution pipe 7 is factory air, and passes into low-pressure gas in the second layer of gas distribution pipe 8, such as low-pressure nitrogen can be passed into, on the above-mentioned distribution pipe evenly distributed with small Hole 9. A cooling coil 2 is arranged outside the collection tank, and the heat exchange medium in the tube is cooling water. High-pressure nitrogen is installed on the top of the waste catalyst collection tank, and the pressure of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com