A high power laser welding head

A high-power, laser technology, applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of laser lens damage, laser welding head burning, laser lens scrapping, etc., to achieve small maintenance, compact structure, welding smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

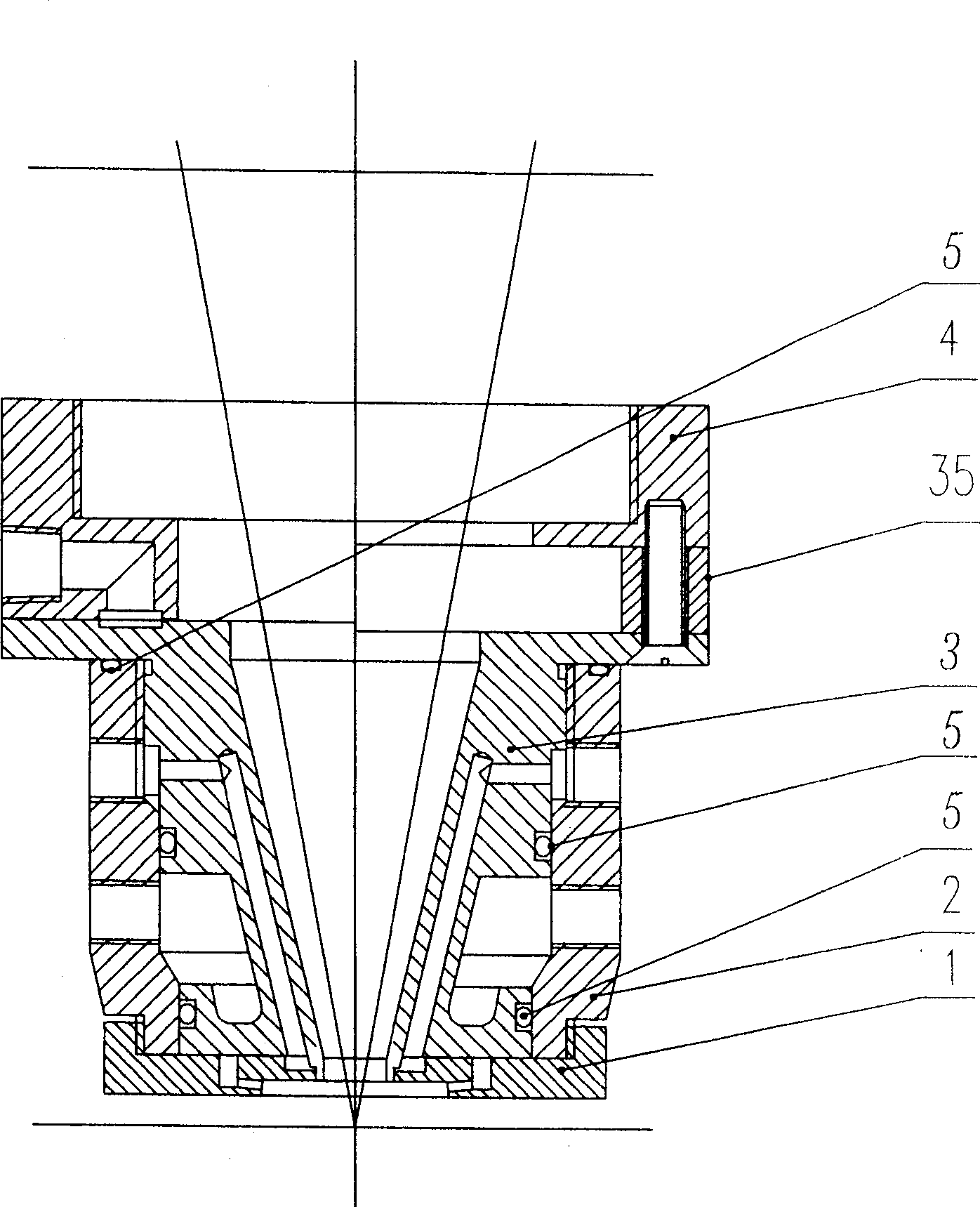

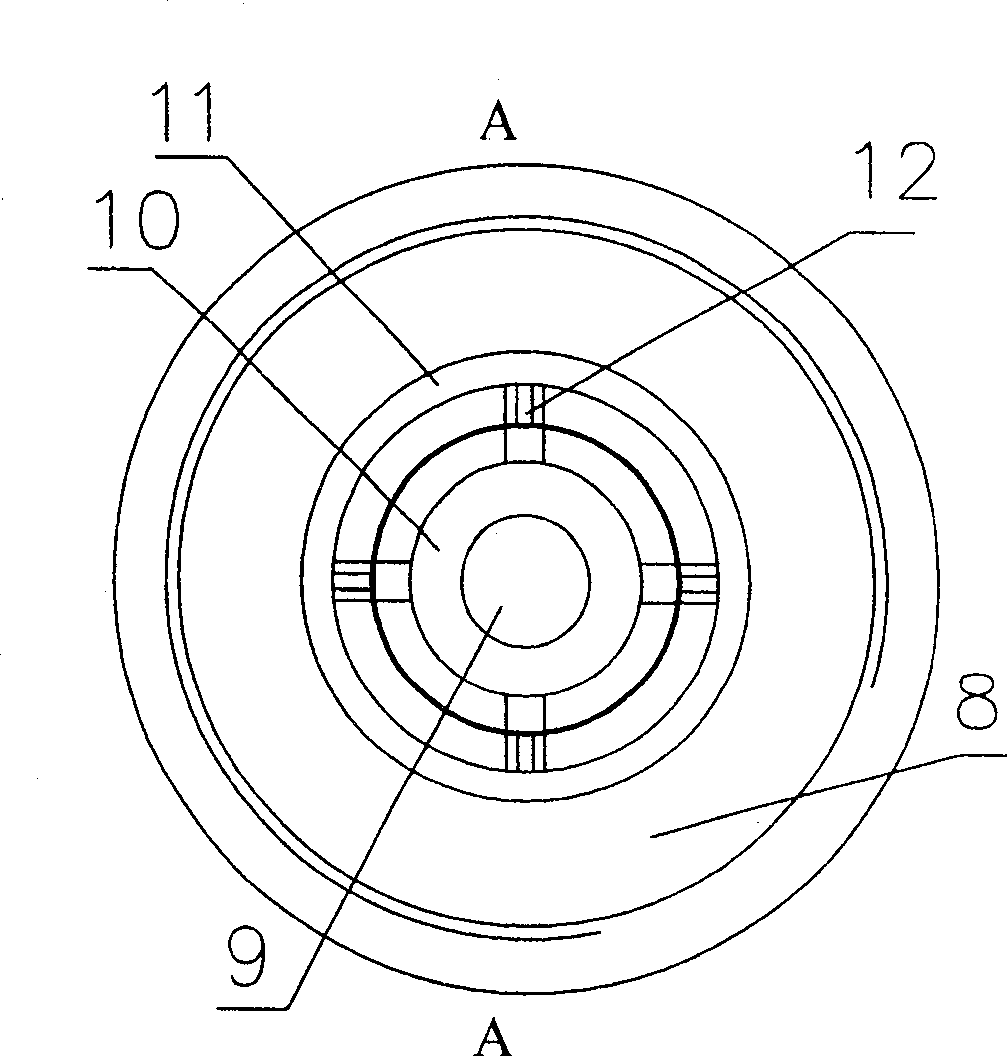

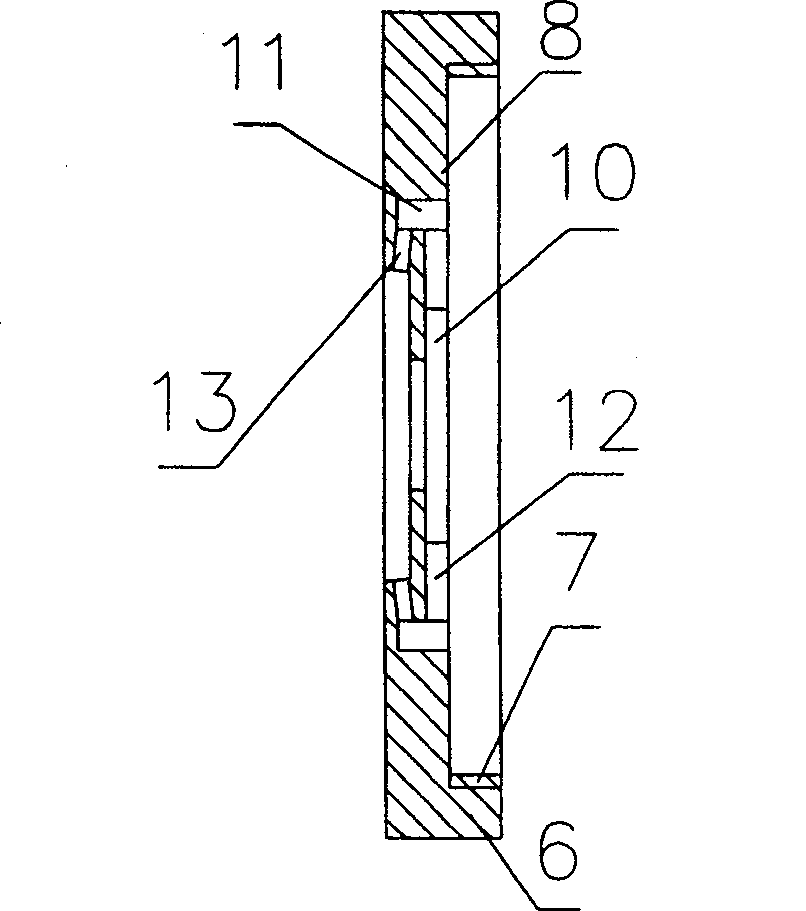

[0035] A high-power laser welding head includes a deflector 1, an outer sleeve 2, an inner sleeve 3, and a joint 4; the deflector 1 is disc-shaped, and a light-transmitting hole 9 is arranged in the center of the deflector 1, which is located outside the light-transmitting hole 9 An inner air ring 10 and an outer air ring 11 are provided, and the inner air ring 10 is connected to the lower end of the air channel 27 provided in the wall of the inner casing 3 .

[0036] The convex edge 6 around the disc-shaped deflector 1 is provided with an internal thread 7, which is threadedly connected with the external thread 15 provided at the lower end of the outer cover 2; The plane 8 and the upper plane 8 are in contact with the lower bottom surface 22 of the outer sleeve 2 and the inner sleeve 3, and a layer of heat-conducting silicone grease is coated on the contact surface to enhance the heat transfer efficiency and facilitate the cooling effect of the laser welding head.

[0037] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com