Interface finishing agent improving rubber-cement stone substrate in rubber concrete

A technology of rubber concrete and interface treatment agent, which is applied in the field of concrete admixture, can solve the problems of human body harmful concrete destructive alkali aggregate reaction, rubber concrete strength not obviously improved, toxicity and volatility, etc., to improve interface bond strength and concrete The effect of overall compressive strength, easy engineering application and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The formula (weight ratio, unit kg) of the composite interface agent is: styrene-acrylic acid ester-silicone coupling agent copolymer accounts for 40-70%, ethylene-vinyl acetate copolymer accounts for 20-40%, PVA coupling agent Agent 10-20%, the three materials are mixed evenly in proportion. The amount of interface agent is 1-2% of the amount of rubber particles. First, dissolve the interface agent in warm water at 40-90°C, fully disperse and stir evenly, then stir the rubber particles and interface agent aqueous solution evenly, and finally place it in a dry ambient until the surface of the rubber particles is completely dry. The rubber particles treated with the interface agent are directly added to the cement concrete for use.

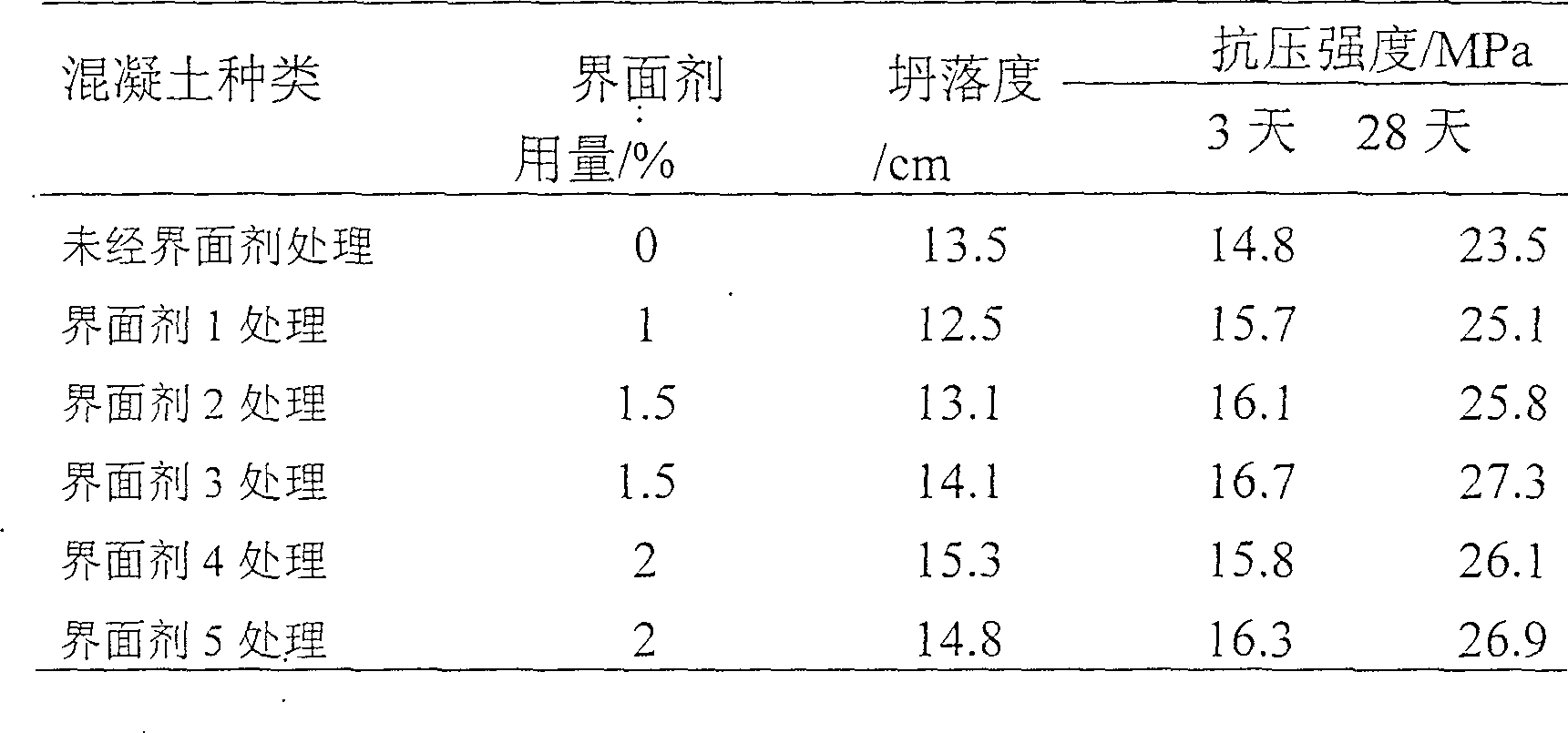

[0010] The basic mixing ratio of rubber aggregate concrete is: cement 450kg / m 3 , water 167kg / m 3 , sand 597kg / m 3 , rubber aggregate 70kg / m 3 , stone 1021kg / m 3 , Naphthalene series superplasticizer 4.5kg / m 3 . The cement is ordinar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com