A shrinkage reducing agent suitable for mass concrete

A large-volume concrete and shrinkage reducing agent technology, applied in the field of materials, can solve problems such as large shrinkage drop, poor compatibility, and adverse effects on strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

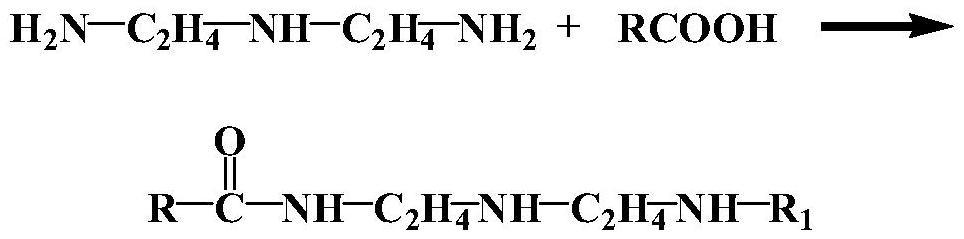

Method used

Image

Examples

Embodiment 1

[0029] A kind of preparation method applicable to shrinkage reducing agent for mass concrete is as follows:

[0030] Put 670g of 2-hydroxysuccinic acid, 550g of diethylenetriamine, and 0.1g of DMAP into a round-necked flask, stir, react for 3 hours, add isopropanol to the beaker for recrystallization, and filter to obtain component A.

[0031] Add 50g of component A, 30g of tripropylene glycol, 10g of neopentyl glycol, and 10g of citric acid into a beaker and stir evenly to obtain the shrinkage reducing agent JS-1.

Embodiment 2

[0033] A kind of preparation method applicable to shrinkage reducing agent for mass concrete is as follows:

[0034] Put 360g of acrylic acid, 550g of diethylenetriamine, and 0.1g of DMAP into a round-necked flask, stir, react for 2.5 hours, add isopropanol to the beaker for recrystallization, and filter to obtain component A.

[0035] Add 50g of component A, 20g of tripropylene glycol, 10g of ethylene glycol, 10g of neopentyl glycol, and 10g of citric acid into a beaker and stir evenly to obtain shrinkage reducing agent JS-2.

Embodiment 3

[0037] A kind of preparation method applicable to shrinkage reducing agent for mass concrete is as follows:

[0038] Put 900g of lactic acid, 550g of diethylenetriamine, and 0.1g of DMAP into a round-necked flask, stir, react for 5 hours, add isopropanol to the beaker for recrystallization, and filter to obtain component A.

[0039] Add 50g of component A, 10g of triglycerol, 10g of ethylene glycol, 20g of neopentyl glycol, and 10g of tartaric acid into a beaker and stir evenly to obtain shrinkage reducing agent JS-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com