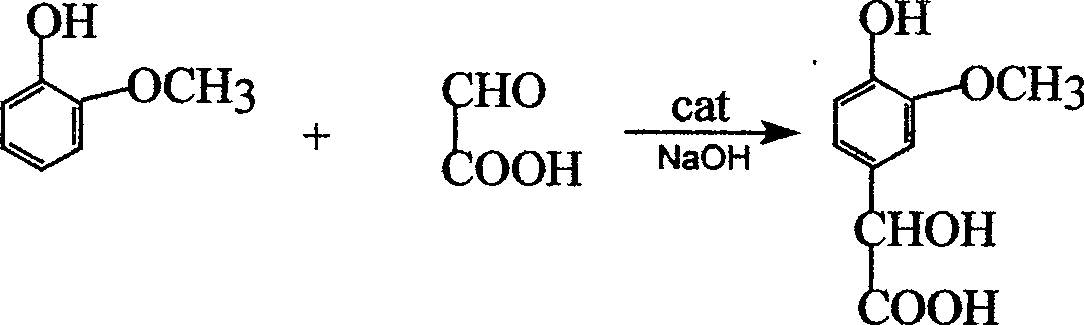

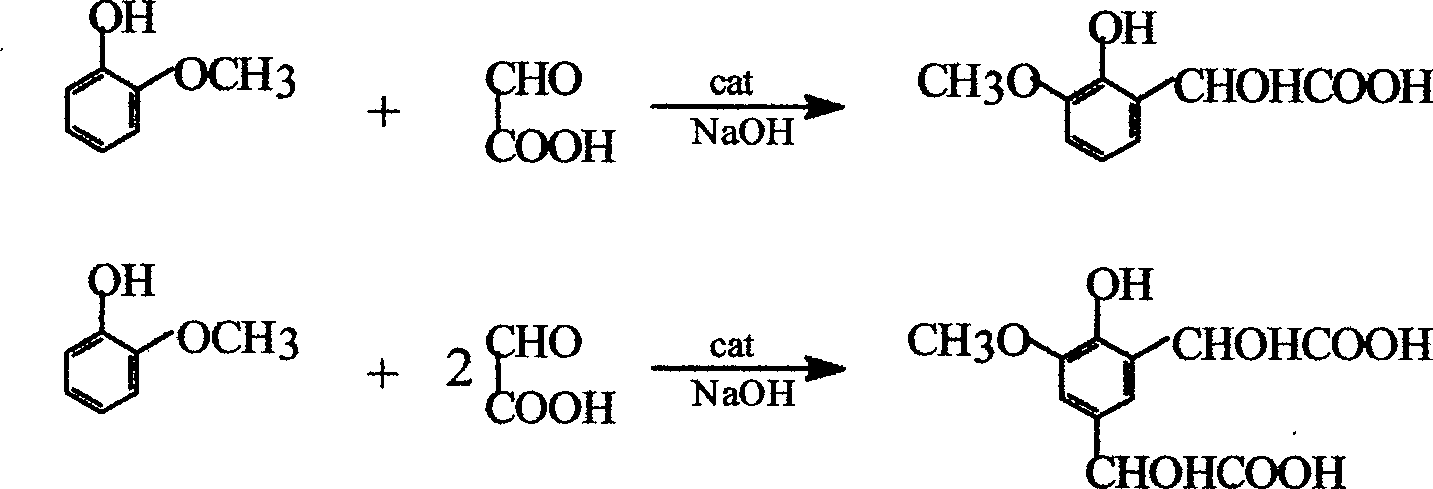

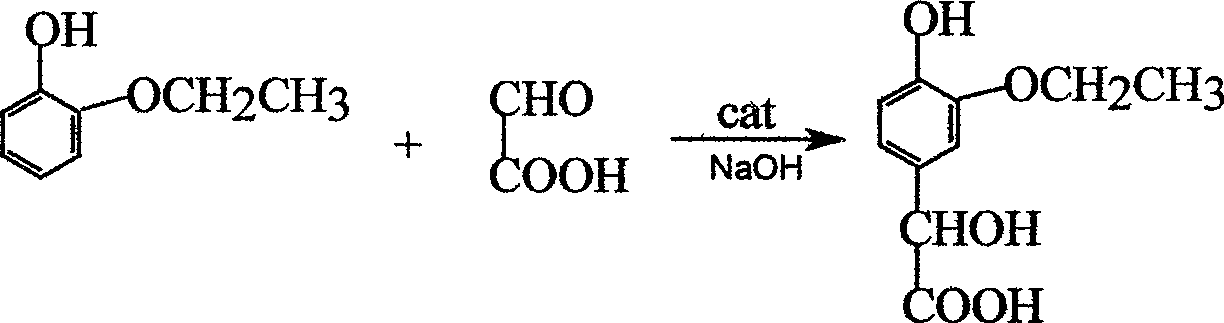

Method of synthesizing 3-methoxy-4-dydroxymandelic acid or 3-ethoxy-4-dydroxymandelic acid by acetaldehyde acid method

A technology of hydroxymandelic acid and glyoxylic acid, applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylate and other directions, can solve problems such as low yield, unsatisfactory yield and the like, achieve mild and stable reaction, The effect of reducing the generation of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Weigh 37g of glyoxylic acid and add it to 57g of water, stir well and set aside.

[0024] (2) Weigh 18.8g of sodium hydroxide and add 140g of water to prepare a sodium hydroxide solution for later use.

[0025] (3) Weigh 27 g of guaiacol with a mass content of 99.4% for later use.

[0026] Weigh 110g of water and add it to the condensation kettle equipped with a constant temperature water bath, agitator and thermometer, start stirring, raise the temperature to 28°C, add 0.5g of catalyst A (tetramethylammonium hydroxide), and then add 17g of the above (2) to prepare After the temperature of the good sodium hydroxide aqueous solution is stabilized, the above-mentioned (1) prepared glyoxylic acid solution, (2) the remaining sodium hydroxide aqueous solution and (3) guaiacol are added dropwise through the three pipelines at the same time. Finished, continue to stir reaction 1h under this condition again. After the reaction, take a sample and analyze the content of 3-m...

Embodiment 2

[0028] According to the operating steps of Example 1, catalyst B (tetramethylammonium chloride), catalyst C (tetramethylammonium bromide), catalyst A plus B (by mass, A: B=1: 1), Catalyst A plus C (by mass, A:C=1:1), catalyst B and C (by mass, B:C=1:1), catalyst A plus B plus C (by mass, A:B : C=1: 2: 2), all the other technological conditions remain unchanged with embodiment 1, and test result sees attached table.

Embodiment 3

[0030] According to the operating steps of embodiment 1, except changing the reaction time, all the other processing conditions are identical with embodiment 1, and test result sees the attached table below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com