High accuracy three-dimensional rocker

A three-dimensional rocker, high-precision technology, applied in the field of rocker, can solve the problems of unable to adjust the lens, unable to meet the use requirements, incomplete images, etc., to achieve the effect of firm structure, easy assembly, and sensitive control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

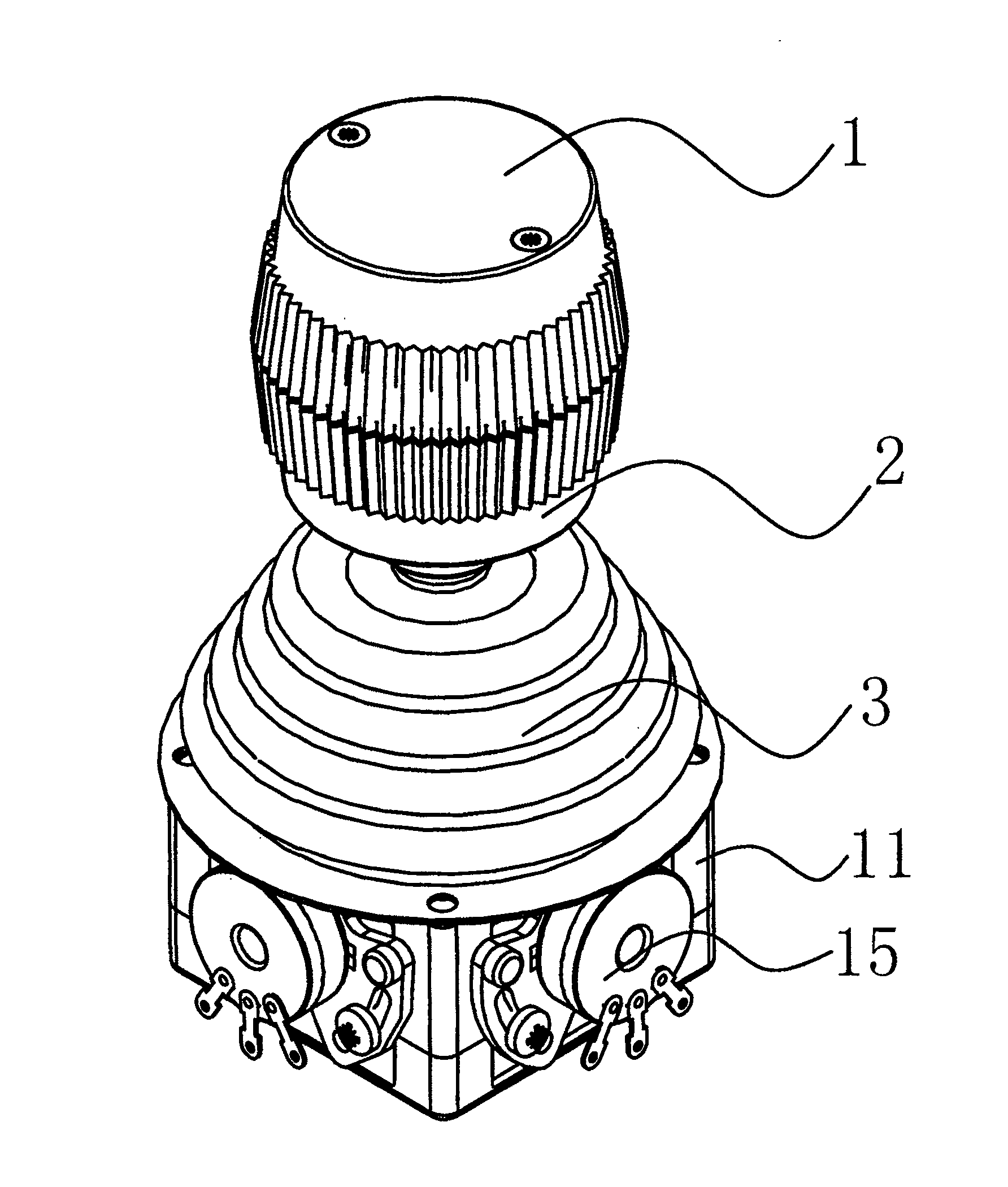

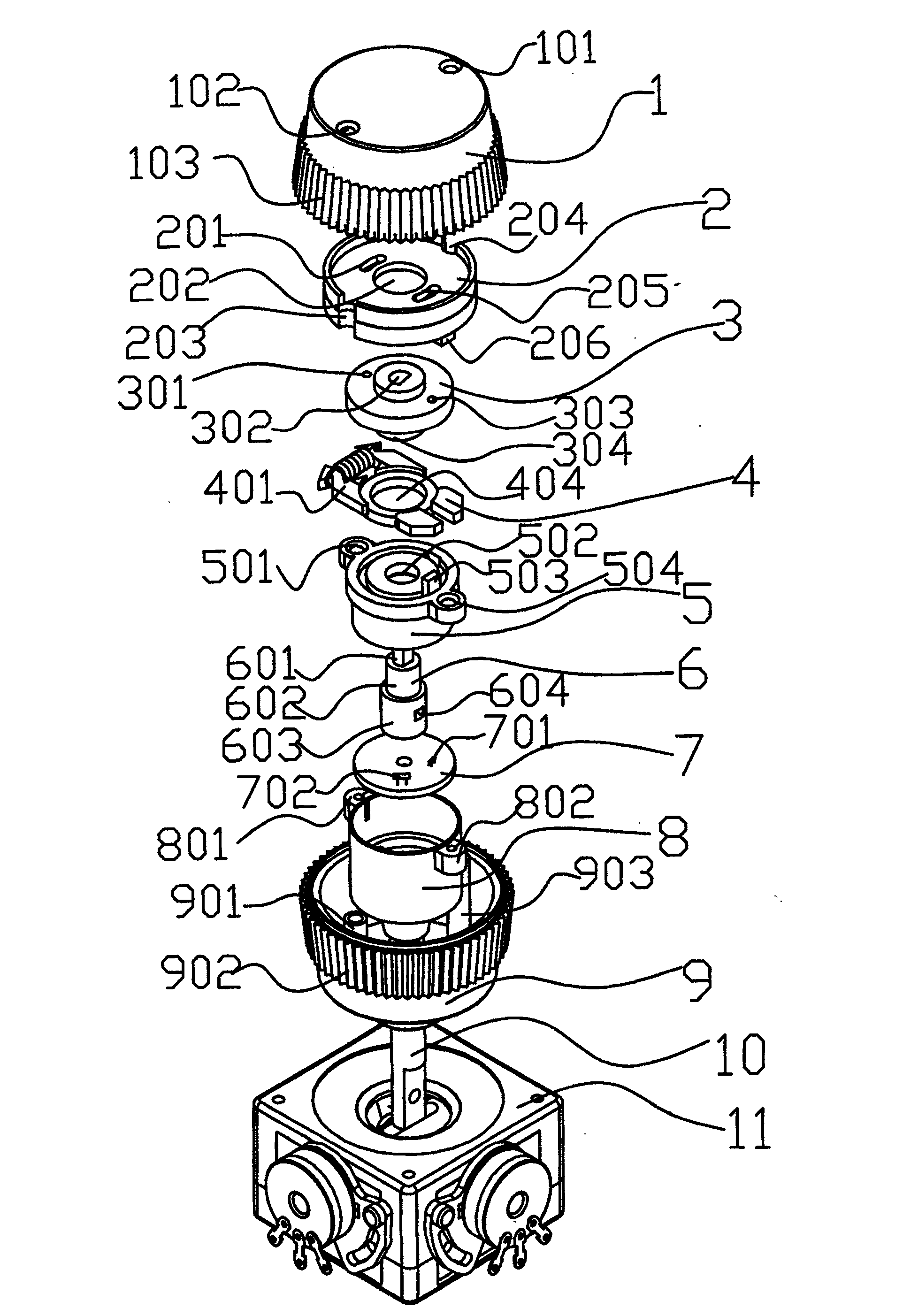

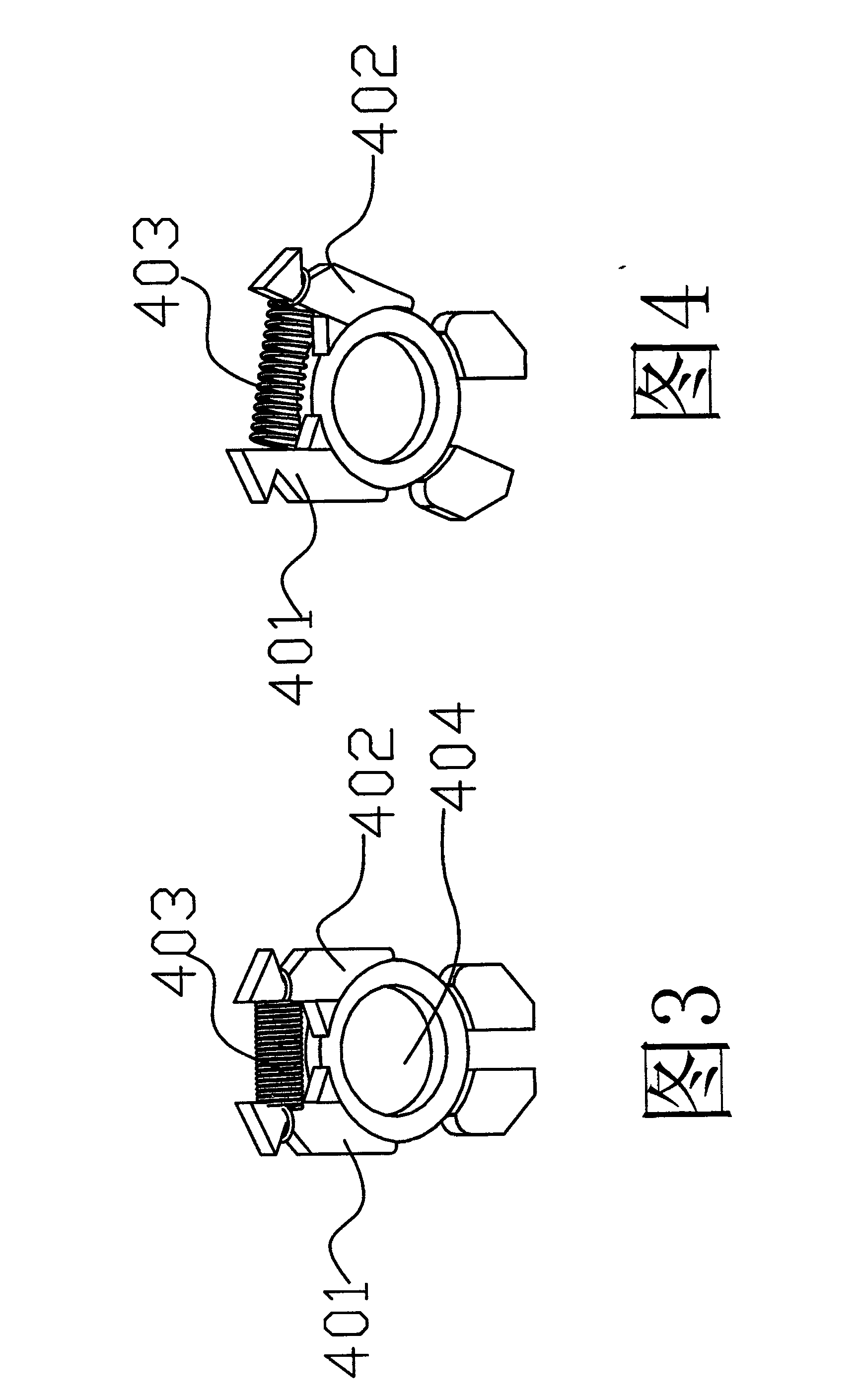

[0023] Embodiment 1: as figure 1 , 2 , 3, and 4, the high-precision three-dimensional rocker includes a base 1, a connecting rod 10 pierced on the base, and a first-direction action device and a second-direction action device installed in the base that are movably connected with the connecting rod 10. Device, the potentiometer 15 that is arranged on the outside of the base and is connected with the first direction action device and the second direction action device respectively (the first direction action device arranged in the base, the second direction action device are mentioned in the background technology in China Patent: 96249825.4 has been described in detail, and will not be described here.), the rocker handle at the other end of the connecting rod is provided with a third direction action device in the rocker handle, and the first The three-direction action device includes a connecting piece 2, a turntable 3, a reset device 4, a circuit board cover 5, a circuit boar...

Embodiment 2

[0032] Embodiment 2: as Figure 5 , 6 As shown, the difference between this embodiment and Embodiment 1 is that the high-precision three-dimensional rocker also includes a center automatic reset device, including a compression spring 12, a circular positioning block 13, and a conical surface 14 arranged on the base. , the positioning block is sleeved on the connecting rod 10, the compression spring 12 is located between the positioning block and the lower cover of the rocker handle, and a shield 12 is also provided outside the central automatic reset device.

[0033] When the rocker is under force, the state after moving is as follows Figure 5 As shown, the connecting rod moves, driving the circular positioning block to move, and the pressure spring shrinks. When the external force disappears, the compression spring naturally stretches, pushing the circular positioning block to move downward, because the circular positioning block is in contact with the conical surface on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com