Nanometer silicon coating surface modifying method for dental non-silicate base ceramic

A technology of surface modification and dental ceramics, applied in dentistry, dental preparations, dental prostheses, etc., can solve the problems of expensive equipment and complex requirements, achieve high practical value, simplify operation steps, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] 1. Preparation of Nano-Silicon Coating

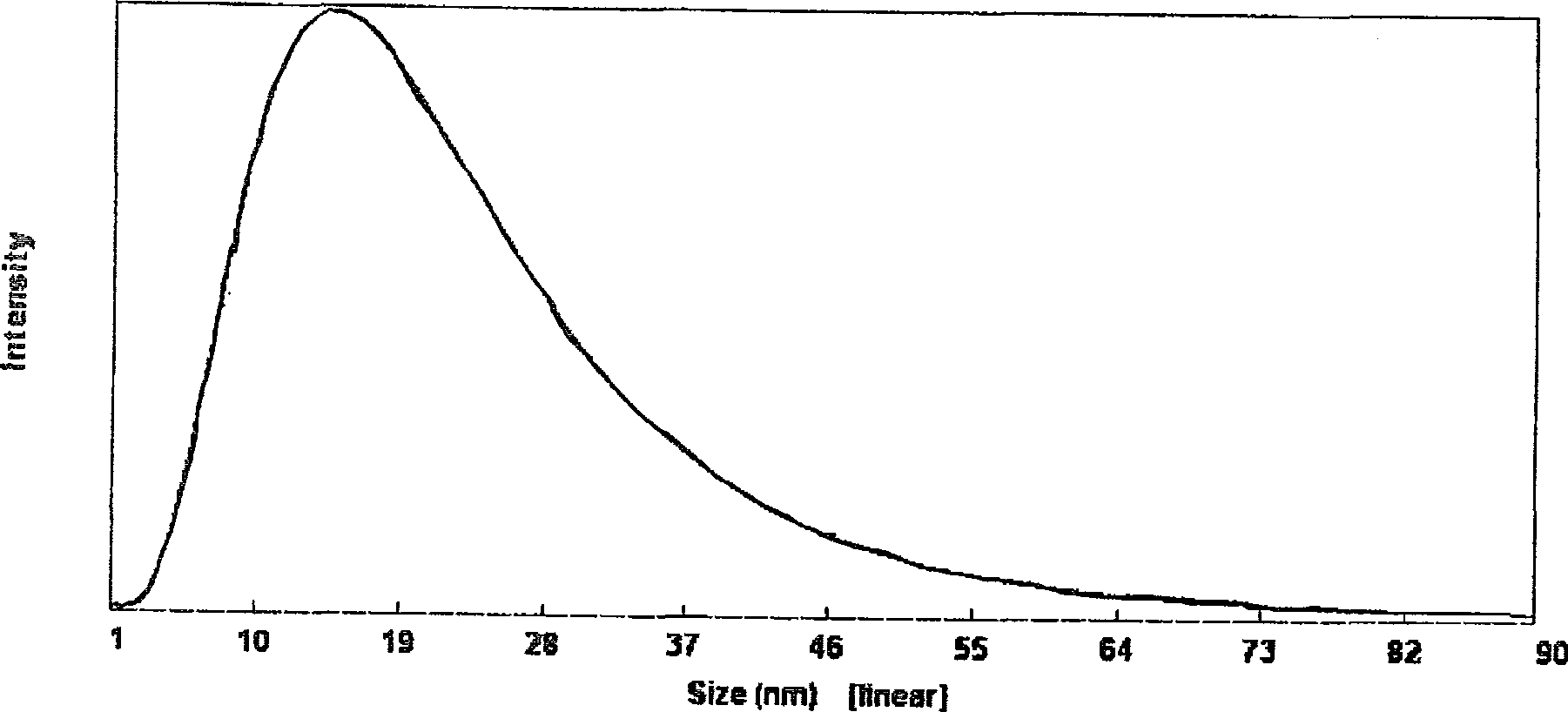

[0020] Select nano-silica sol with a concentration of 40%, the average particle size of silicon oxide particles in the sol is 16.6nm, the standard deviation is 8.1nm, the minimum particle diameter is 3nm, and the maximum is 100nm. figure 1 The particle size analysis of nano-silica sol (temperature 25°C) shows the specific distribution of intensity values of particles of various sizes in the sol.

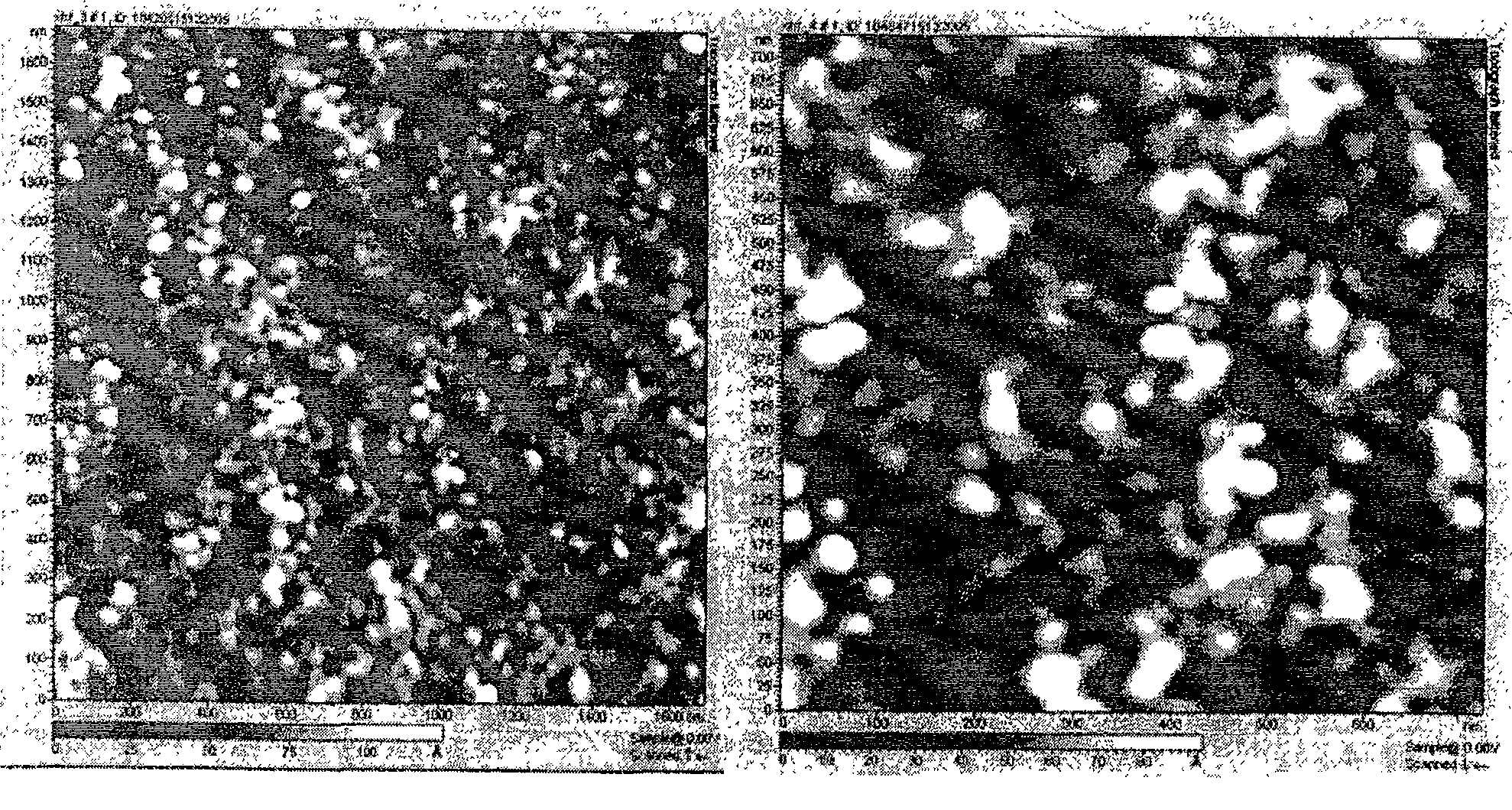

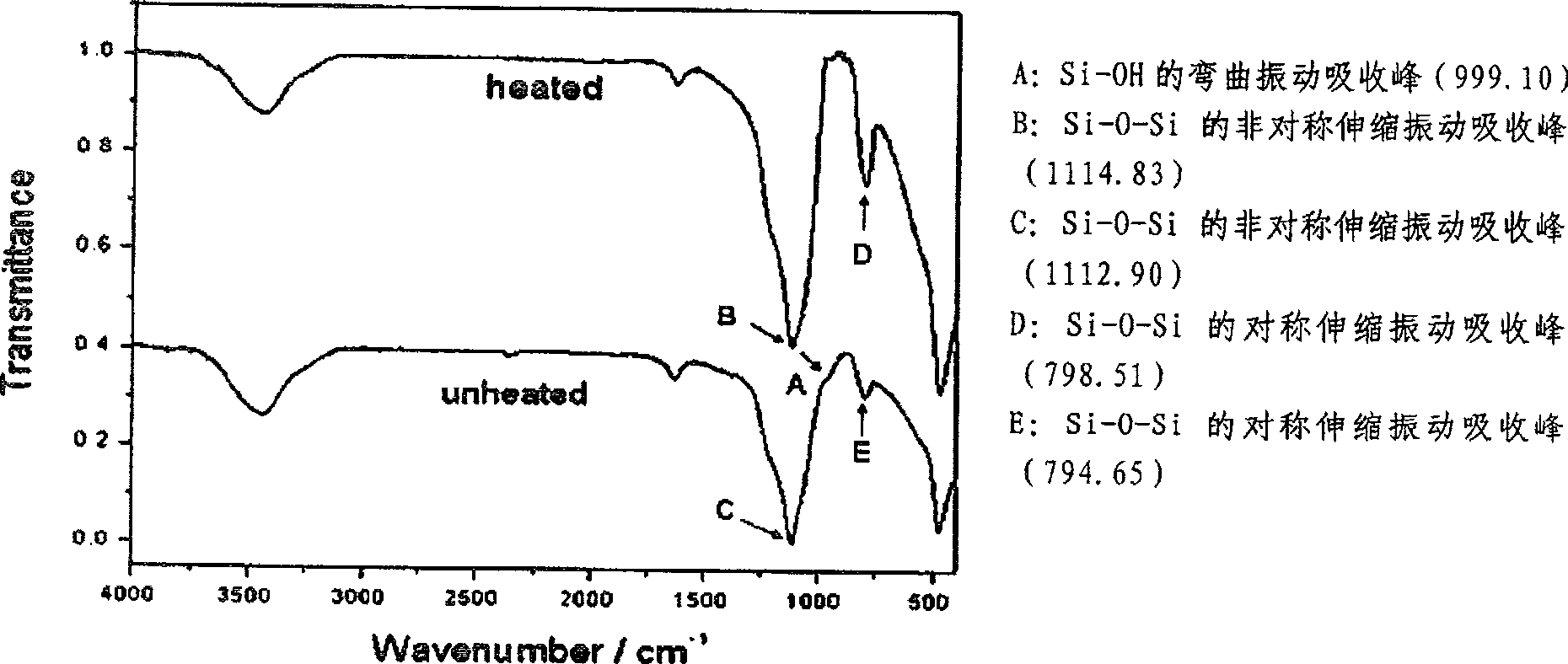

[0021] The sintering and glass infiltration of In-Ceram alumina ceramics (VITA, Germany) are completed in the laboratory in turn, and made into 10×5×1mm 3 The substrate was sandblasted with 110 μm alumina for 20 seconds at a place 10 mm away from the surface of the substrate under a pressure of 0.2 MPa, ultrasonically cleaned in anhydrous ethanol for 10 minutes, and then dipped in a small amount of nano-silica sol with a small brush with a width of 10 mm (so that the brush is wet but without liquid) Drop formation) along the long axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com