Laser processor

A laser processing machine and laser beam technology, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of time-consuming, workpiece 2 damage, increase production cost, etc., to reduce production cost, ensure processing range, The effect of increasing the processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

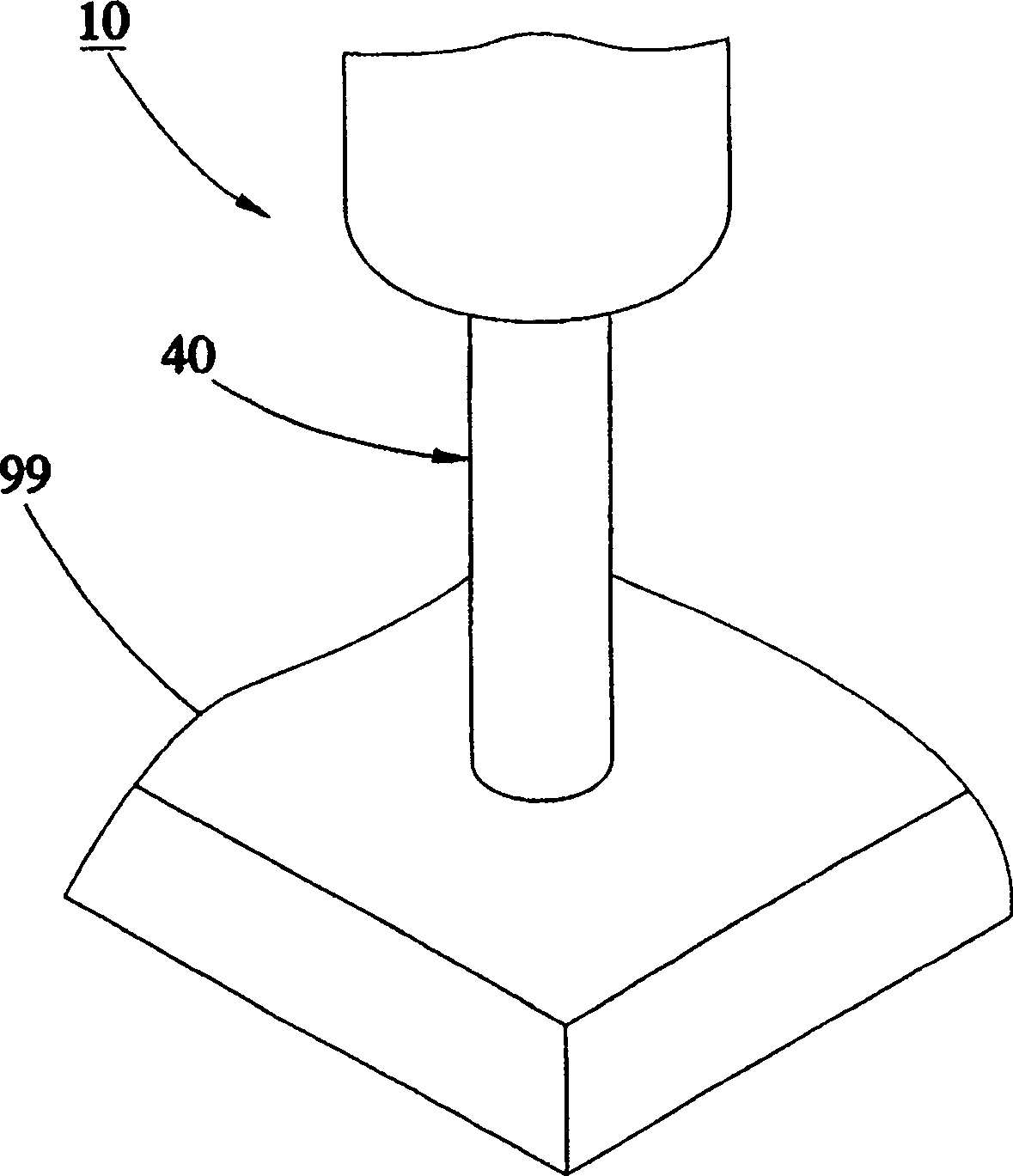

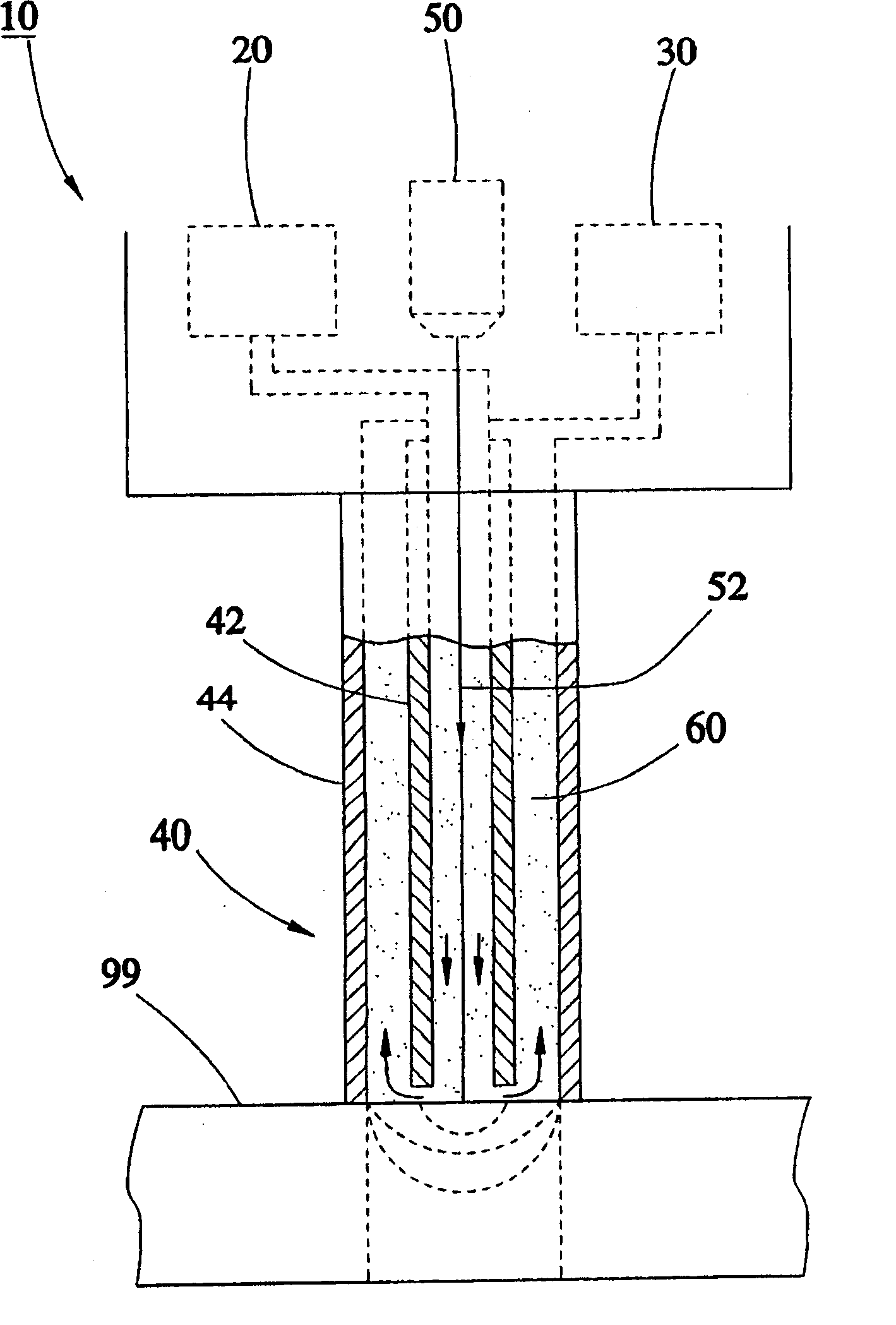

[0028] see Figure 2 to Figure 4 , the laser processing machine 10 provided by the first preferred embodiment of the present invention can process a workpiece 99, the laser processing machine 10 includes a supply device 20, a recovery device 30, an actuating device 40 and a laser device 50 .

[0029] The supply device 20 is used to output a fluid 60; wherein, the fluid 60 is selected from air, oxygen, carbon monoxide, carbon dioxide, nitrogen, inert gas, water or chemical liquid, and the chemical liquid is selected from One of the group consisting of sulfuric acid, hydrochloric acid, sodium nitrate, salts, sodium hydroxide, potassium hydroxide, and hydrofluoric acid. In this embodiment, the fluid 60 is selected as hydrochloric acid as an example.

[0030] The recovering device 30 is used for receiving the fluid 60 passing through the actuating device 40 and flowing through the workpiece 99 .

[0031] The actuating device 40 has a first guide part 42 and a second guide part 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com