Low temperature valve performance measuring system based on computer data acquiring

A technology of data acquisition and testing system, which is applied in the testing of machine/structural components, liquid tightness measurement using liquid/vacuum degree, measuring device, etc. Discontinuity and other problems, to achieve the effect of facilitating unified storage and management, improving work efficiency, and ensuring personnel safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

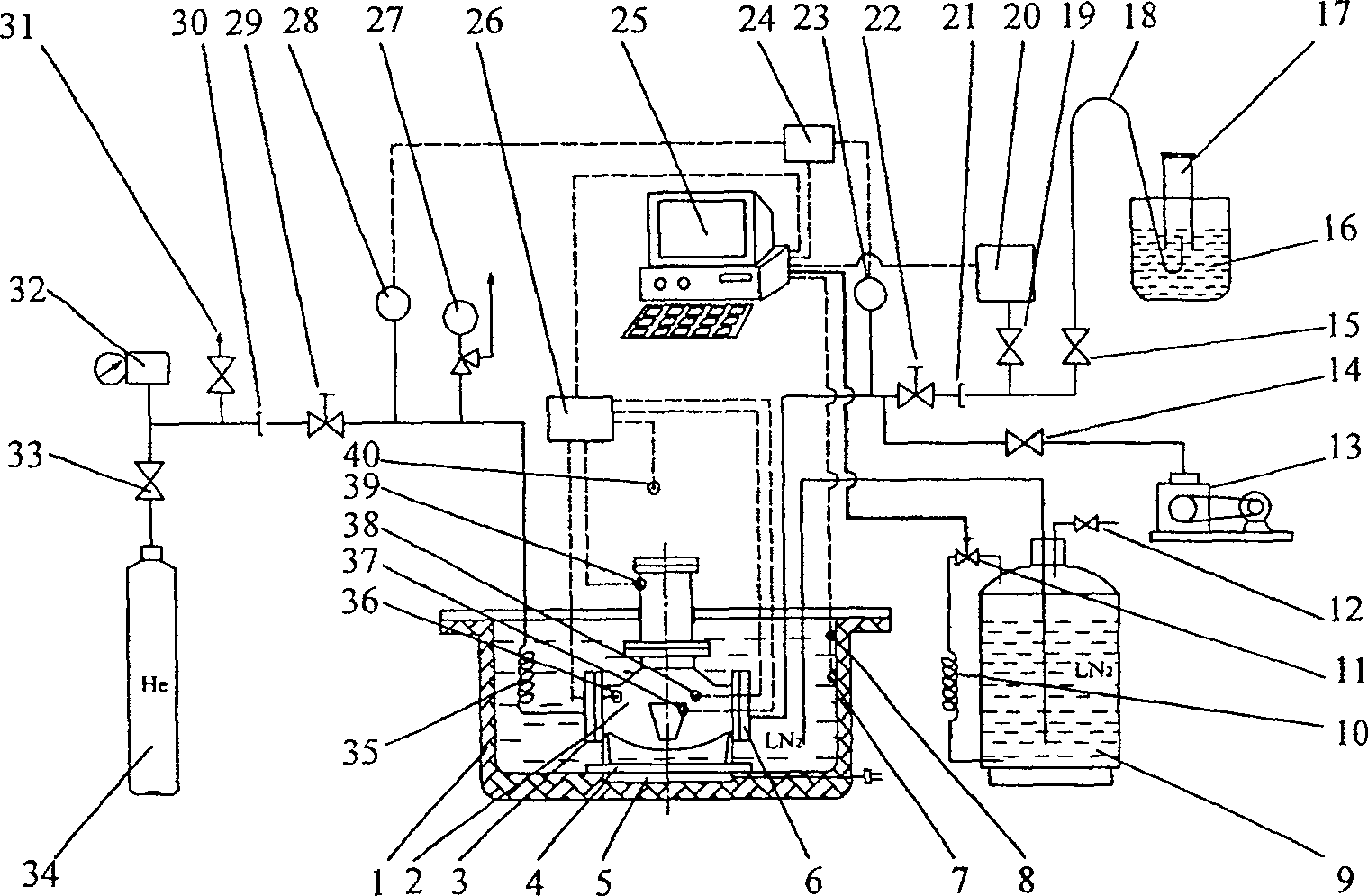

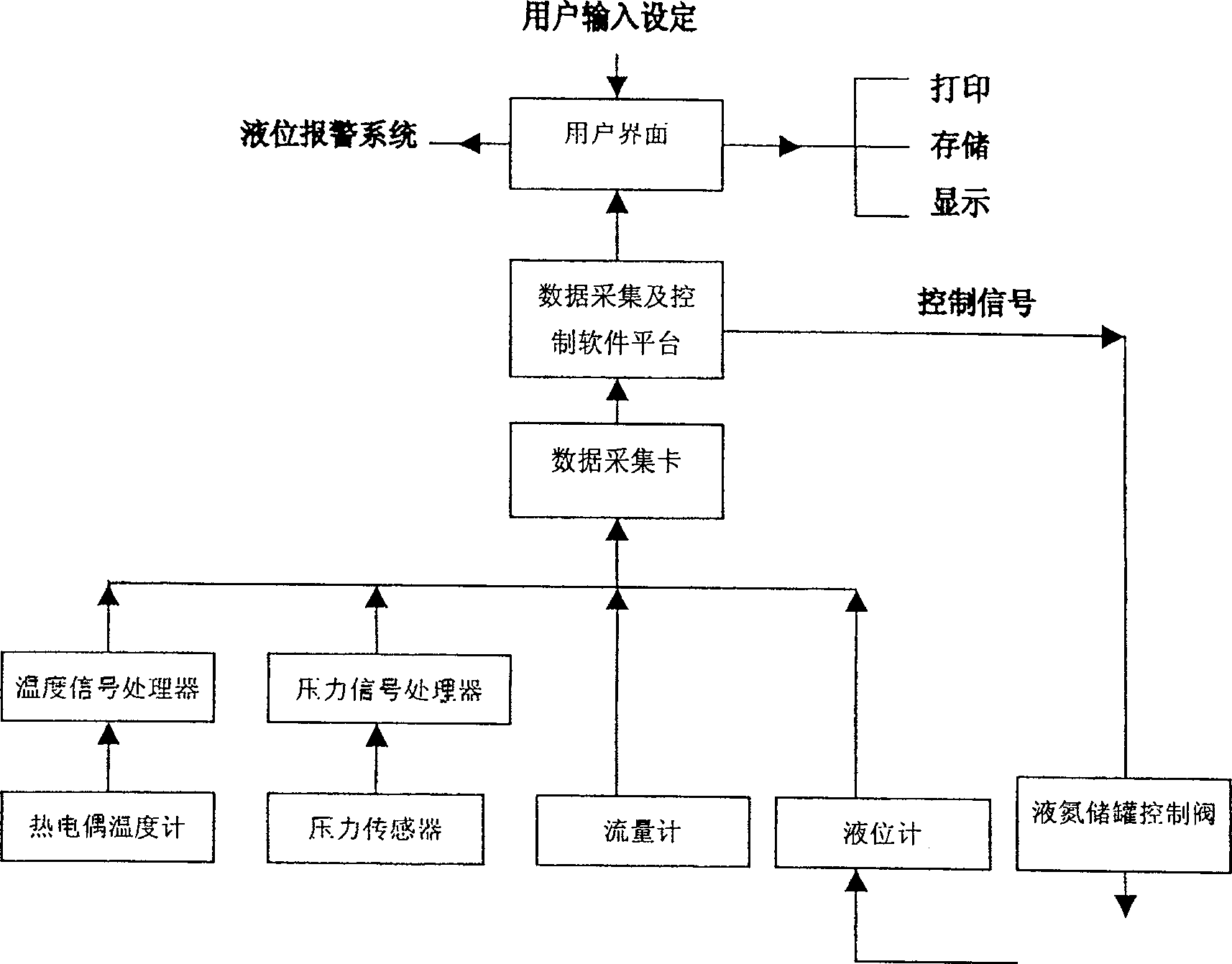

[0010] The low-temperature valve performance test system based on computer data collection has a low-temperature test tank 1. The low-temperature test tank 1 is fixed with a mounting base 4 and an electromagnet 5. The low-temperature test tank 1 also has an upstream method connected with the cryogenic valve 2 to be tested The flange end cover 3 and the downstream flange end cover 6 connected to the cryogenic valve 2 to be tested. The upstream flange end cover 3 is sequentially connected with the gas coil 35, the safety valve 27, the upstream pressure sensor 28, and the upstream pipeline stop valve 29 , Upstream quick connector 30, drain valve 31, pressure reducing valve 32, helium cylinder stop valve 33, helium cylinder 34; downstream flange end cap 6 is connected to downstream pressure sensor 23, downstream pipeline stop valve 22, downstream rapid Connector 21, shut-off valve 19, shut-off valve 15, hose 18, water tank 16, measuring cylinder 17, the other end of shut-off valve 19 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com