Plate type cold trap for freeze-dryer

A freeze dryer and cold trap technology, which is applied in the field of plate cold traps for freeze dryers, can solve the problem that the power per unit surface area is not suitable for large freeze dryers, the heat exchange area is not fully utilized, and the tubular cold trap traps Water efficiency is low and other problems, to achieve the effect of shortening pre-evacuation time, shortening defrosting time, and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

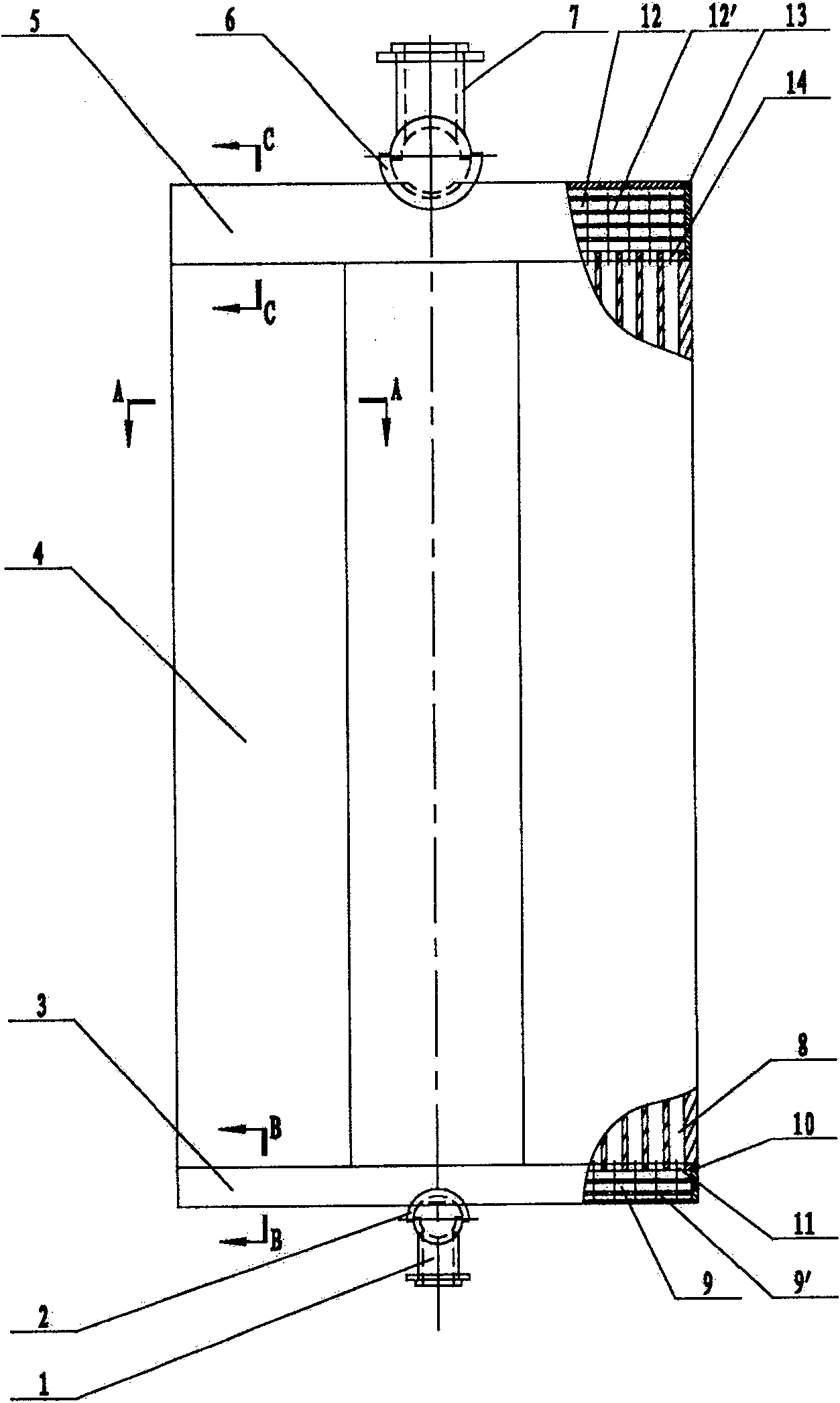

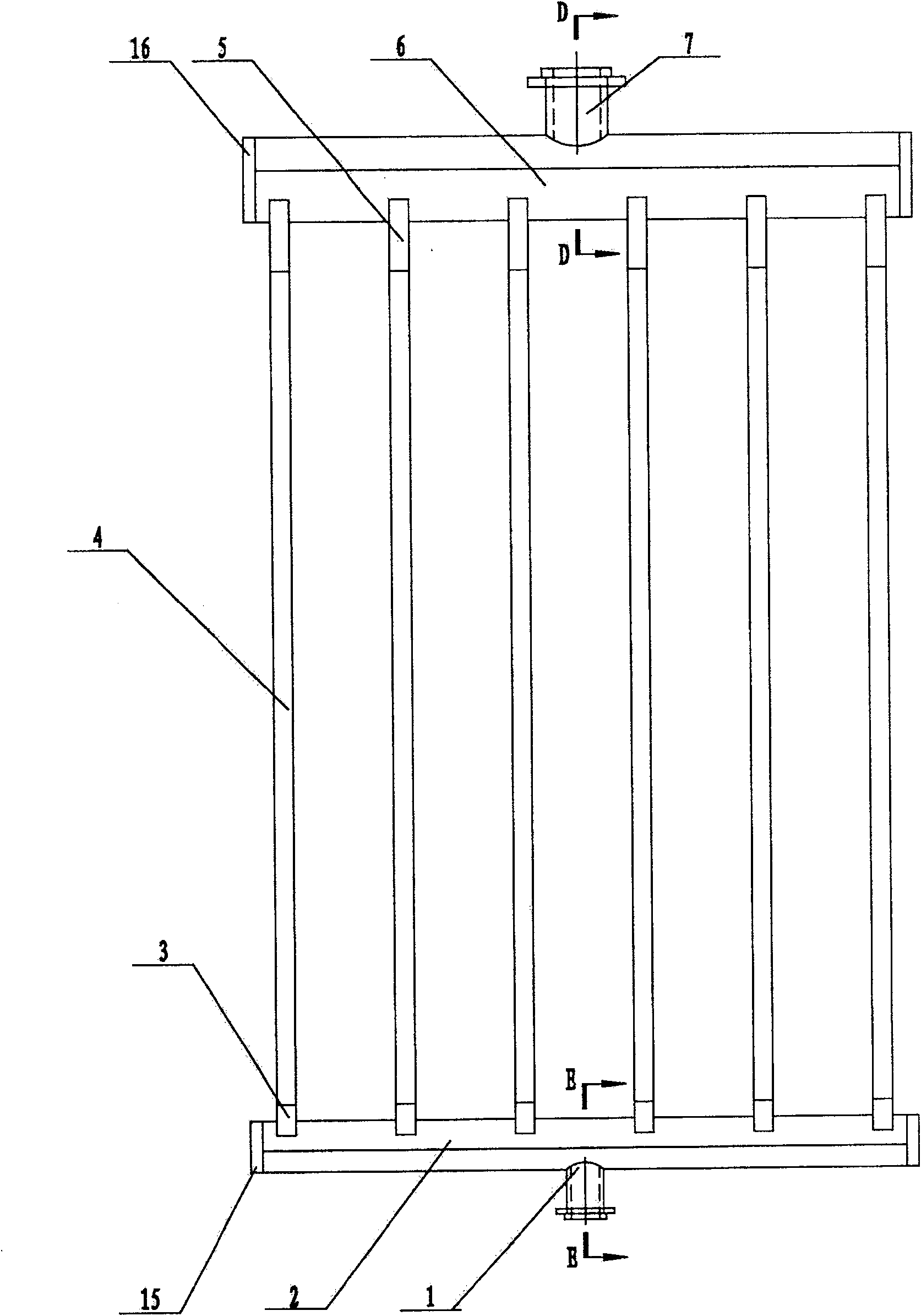

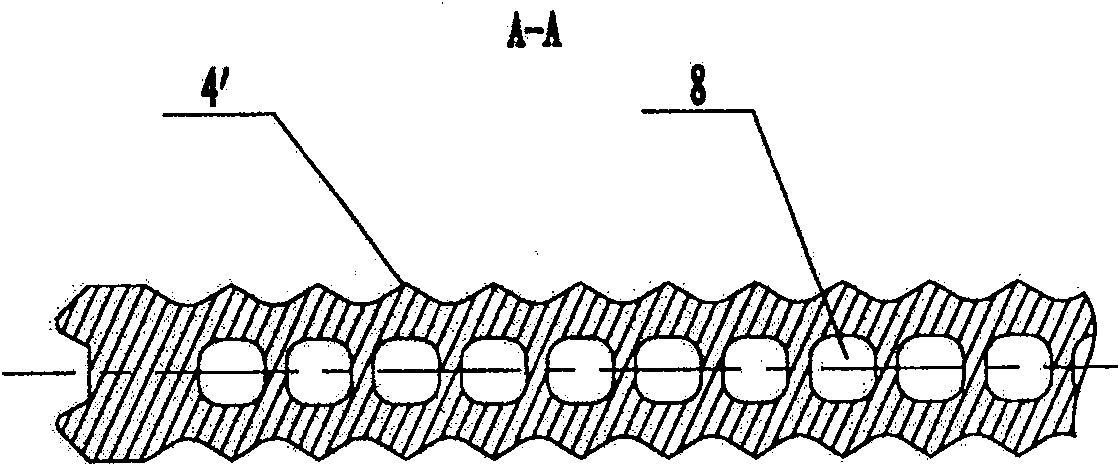

[0028] Such as figure 1 , 2 , is a schematic diagram of a plate-type cold trap for a freeze dryer, showing a liquid supply main pipe 1, a liquid supply cross header 2, a liquid supply small header 3, a cold trap main board 4, a return small header 5, a return flow Horizontal header box 6 and reflux main pipe 7; several cold trap main boards 4 are arranged in parallel and equidistant or fan-shaped. This scheme is arranged in parallel and equidistant. The lower ends of the small liquid supply headers 3 are installed on the liquid supply cross header 2, and the liquid supply main pipe 1 is installed on the lower side of the liquid supply cross header 2; the upper end of each cold trap main board 4 is equipped with a return flow box 5; the upper end of each small return header 5 is installed on the return cross header 6, and the return main pipe 7 is installed on the upper side of the return cross header 6; each piece has a flow channel inside, and each piece The flow passages a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com