Thermosetting plastic injection transfer moulding method and its mould

An injection molding, thermosetting technology, applied in a molding method and the mold field used, can solve the problems of high material flow rate at the gate, poor labor conditions, low material utilization rate, etc., and achieves low injection resistance and accelerated curing. Forming, high mechanical strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

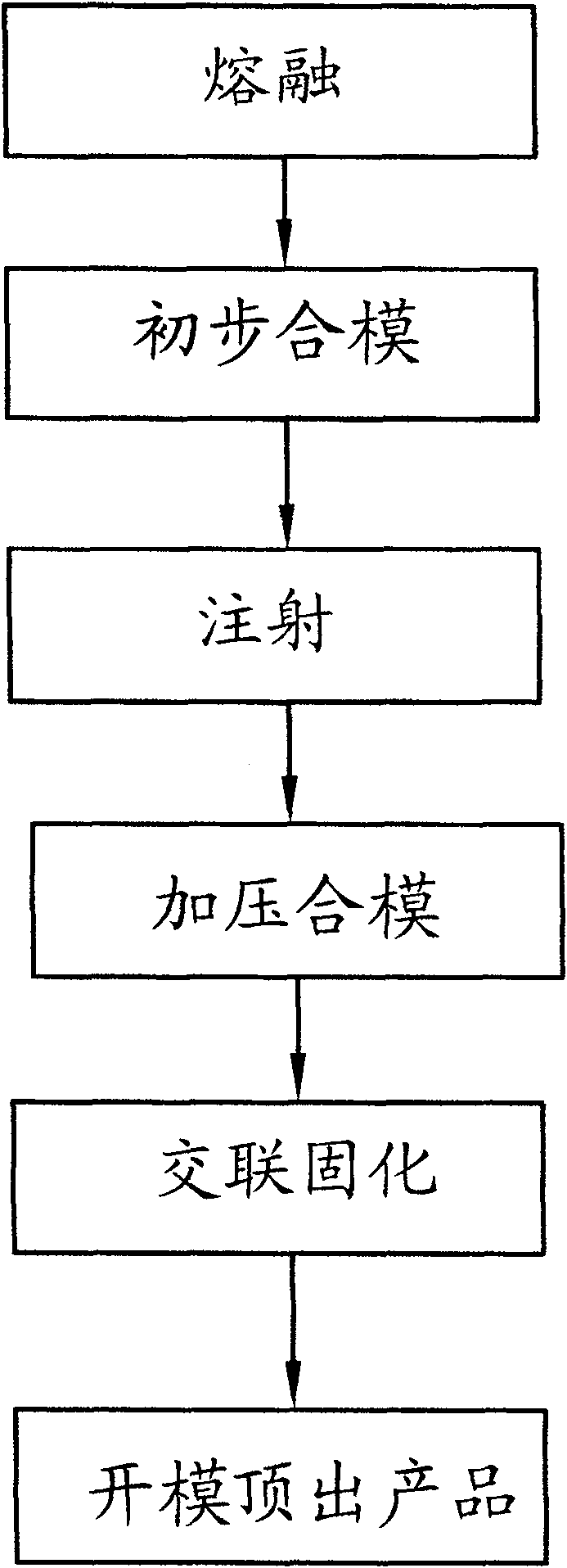

[0037] One: The production process of thermosetting plastic injection molding method; the material used is phenolic resin.

[0038] (1): Put the phenolic resin material into the barrel of the injection machine to heat and melt;

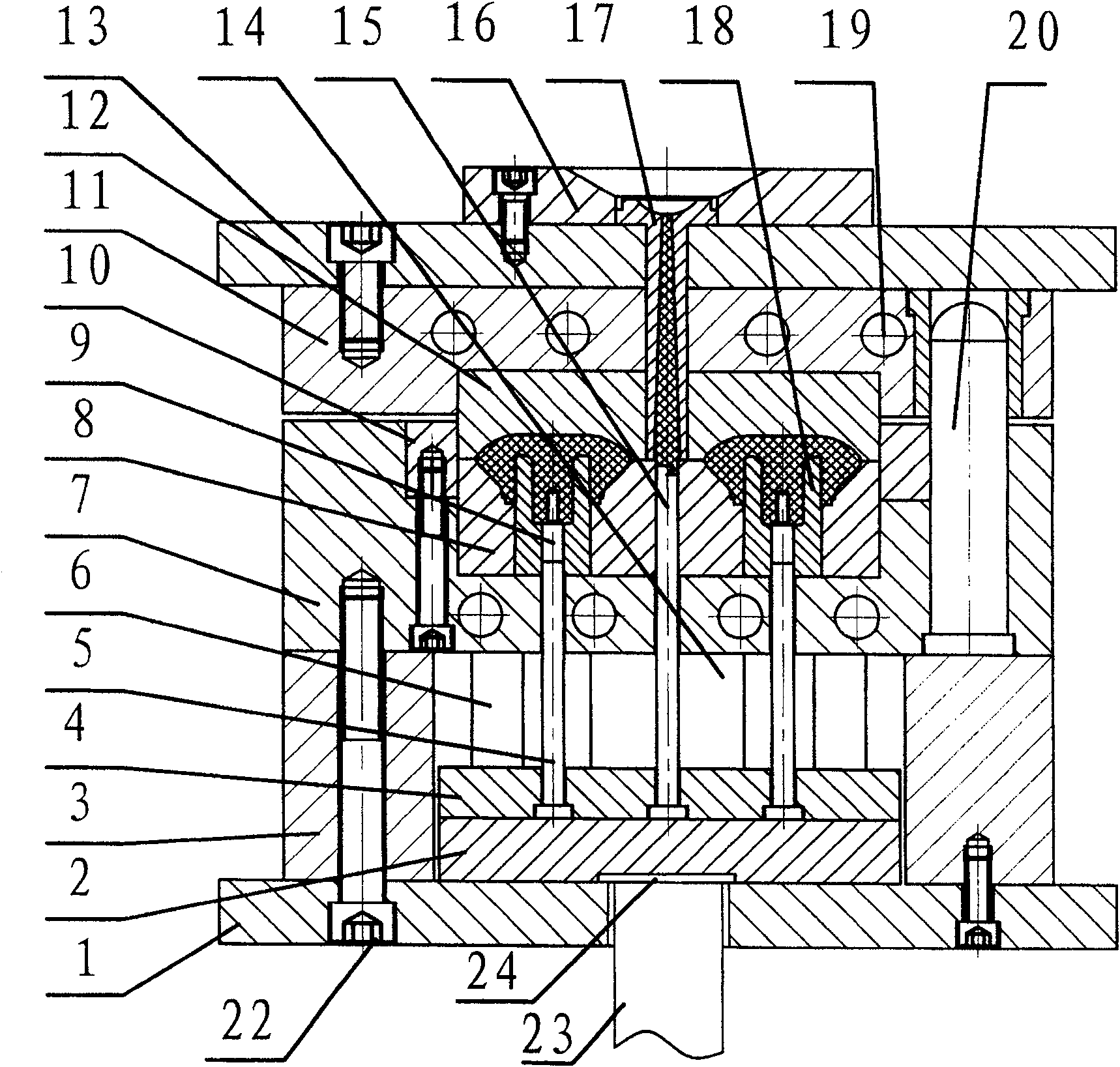

[0039] (2): After closing the mold, reset the ejector slider of the mold, slightly open the mold so that the upper mold core, lower mold core and material cavity insert ring of the mold form a closed feeding cavity; among them, the distance between the upper mold core and the lower template is controlled about 4mm;

[0040] (3): Inject the molten phenolic resin material into the feeding chamber through the nozzle of the injection machine; set the amount of injected phenolic resin according to the gross weight of the product;

[0041] (4): The upper mold core and the lower mold core of the mold are completely closed by pressing the mold to press the phenolic resin material in the feeding cavity into the cavity;

[0042] (5): Keep the phenolic resin m...

Embodiment 2

[0049] One: The production process of thermosetting plastic injection molding method; the material used is melamine.

[0050] (1): Put the melamine material into the barrel of the injection machine to heat and melt;

[0051] (2): After closing the mold, reset the ejector slider of the mold, slightly open the mold so that the upper mold core, lower mold core and material cavity insert ring of the mold form a closed feeding cavity; among them, the distance between the upper mold core and the lower template is controlled about 10mm;

[0052] (3): Inject the molten melamine material into the feeding chamber through the nozzle of the injection machine; set the amount of melamine injected according to the gross weight of the product;

[0053] (4): The upper mold core and the lower mold core of the mold are completely closed by pressing the mold to press the melamine material in the feeding cavity into the cavity;

[0054] (5): Keep the melamine material in the mold cavity at 170°C...

Embodiment 3

[0058] One: The production process of thermosetting plastic injection molding method; the material used is BMC (BMC is the abbreviation of bulk unsaturated polyester).

[0059] (1): Put the BMC material into the barrel of the injection machine to heat and melt;

[0060] (2): After closing the mold, reset the ejector slider of the mold, slightly open the mold so that the upper mold core, lower mold core and material cavity insert ring of the mold form a closed feeding cavity; among them, the distance between the upper mold core and the lower template is controlled about 7mm;

[0061] (3): Inject the molten BMC material into the feeding cavity through the nozzle of the injection machine; set the amount of injected phenolic resin according to the gross weight of the product;

[0062] (4): The upper mold core and the lower mold core of the mold are completely closed by pressing the mold to press the BMC material in the feeding cavity into the cavity;

[0063] (5): Keep the BMC m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com