Vertical dry-cutting water-cooling plastic granulator

A vertical and granulator technology, applied in the field of vertical dry-cut plastic granulators, can solve the problems of high running speed of granules, short cooling time, difficult to remove, etc., and achieve uniform granule shape, good cooling effect and increased output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

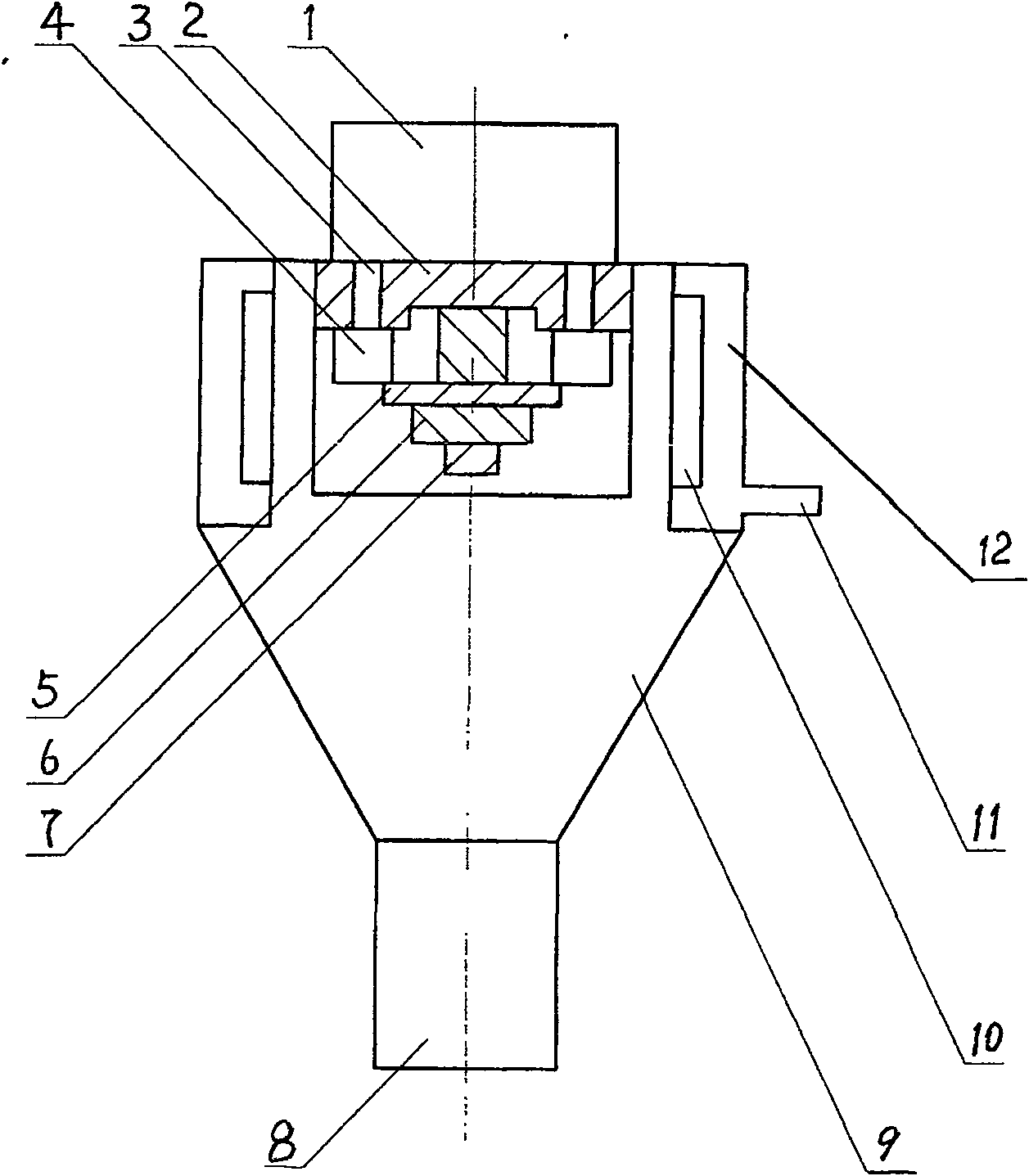

[0010] like figure 1 As shown, the embodiment of the present invention includes a machine head 1 with a power device, a discharge template 2 fixed on the machine head 1 and a cutter 4 fixed at the lower end of the machine head 1 . There are several discharge holes 3 on the discharge template 2 . Cutter 4 is installed on the cutter frame 5 . Cutter rest 5 is then installed on the head axis 7 by fixed nut 6.

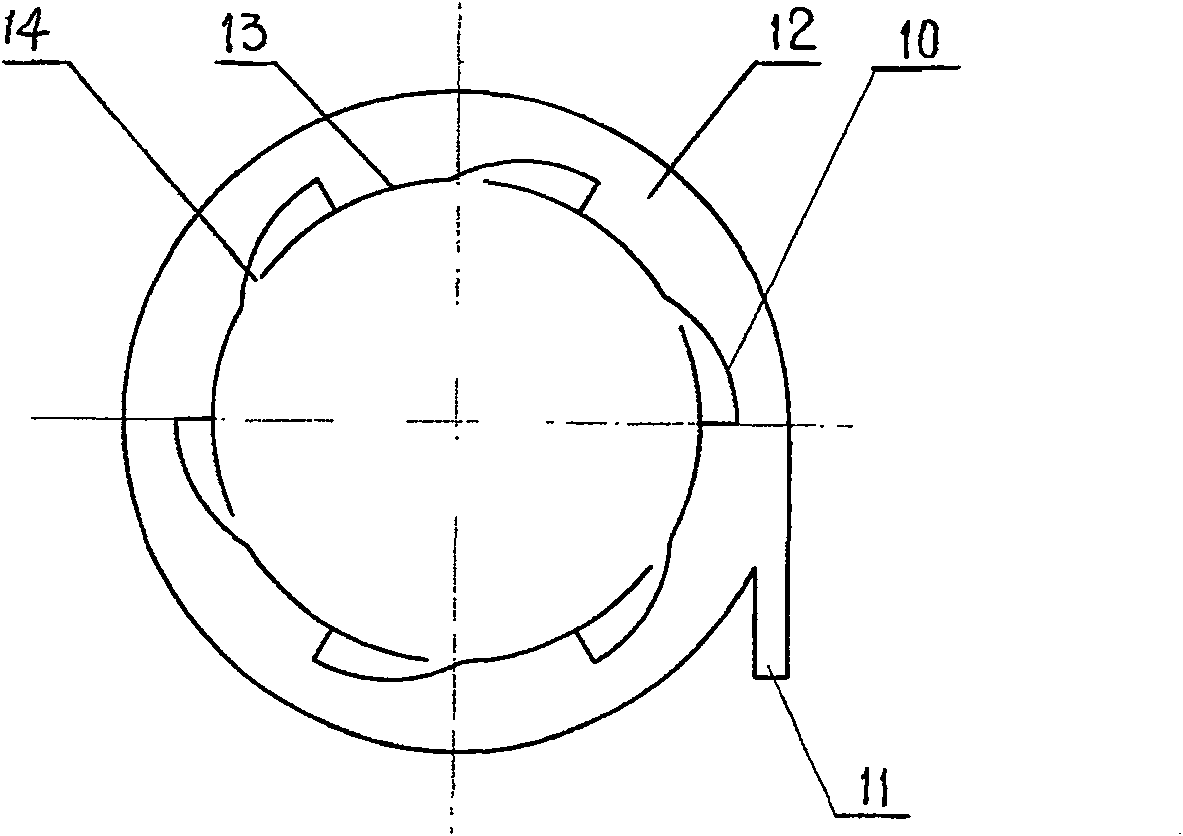

[0011] like figure 1 , 2 As shown, a pelletizing chamber 9 is arranged below the machine head 1 , the upper end of the pelletizing chamber 9 is closed, and the lower end has a pellet outlet 8 . The upper part of the cutting chamber 9, that is, a section around the cutting knife 4, is in the shape of a sandwich cylinder. The annular cylinder wall interlayer 12 has two closed end faces up and down and has a water inlet pipe 11, and several water spray slits 14 are evenly distributed on the inner cylinder wall 13, and these water spray slits 14 are all along the inner wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com